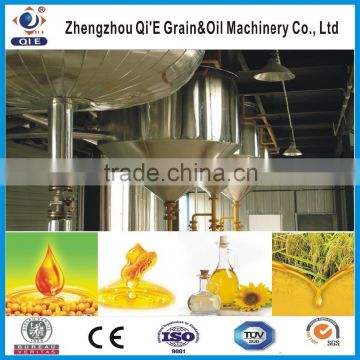

Edible Soybean Oil Refinery Plant.edible Oil Refinery Plant,cooking Cooking Oil Refinery Plant

edible soybean oil refinery plant

Refining process of edible soybean oil refinery plant

Crude oil → Degumming section → Decolorizing section → Deodorization section → Filter → End product oil

*** Degumming section: under 60-70°C,it occurs acid-base neutralization reaction with sodium hydroxide ,After stirring by reduction box,it can decrease the acid value in oil and separate the impurity ,phospholipid which will enter into soap stock.The oil can be refined further.

*** Decolorizing section:it removes water from oil by vacuum.The bleaching earth is breathed into bleaching pot ,after stirring,filtrated by filter and change the color of the oil.

*** Deodorization setion: The qualified decolored oil enters into the spiral plate heat exchanger to recover most of the heat, and next goes to high pressure steam heat exchanger to be heated to the process temperature (240-260°C) and then enters the deodorization tower. The upper layer of combined deodorization tower is the packing structure which is mainly used to remove the odor producing components such as free fatty acid (FFA);the bottom layer is the plate tower which is mainly for achieving the hot decoloring effect and reducing the peroxide value of the oil to zero.

Refining method of edible soybean oil refinery plant

| 1 | Chemical refining |

| 2 | Physical refining |

| 3 | Chemical and physical refining |

Final oil quality of edible soybean oil refinery plant

| 1 | Grade one for salad oil |

| 2 | Grade two for high quality cooking oil |

| 3 | Grade three and four for cooking oil |

Send Inquiry to This Supplier

You May Also Like

-

Hot Selling Electric Feed Pusher High Productivity Core Motor Grass Pushing Machine New Management Equipment for Livestock FarmsUS$ 4650.00MOQ: 1 Set

-

New Household Electric Corn Grinder With Chili Seasoning Production Line Maltose Jujube Kernel CrusherUS$ 1050.00MOQ: 1 Piece

-

Hay Cutting MachineUS$ 1000 - 2000MOQ: 1 Set

-

Portable / Mobile Grain Suction Machine With Soft PipesUS$ 490 - 1,500MOQ: 1 Set

-

Corn Straw Small Animal Feed Grinder, Small Corn Mill Grinder for Sale, Small Corn Mill Grinder for SaleUS$ 1,000 - 1,200MOQ: 1 Set

-

Farm Machinery / Cultivator / Rotavator / Rotary TillerUS$ 600 - 900MOQ: 6 Units

-

CBRL Farm Machine Ginger HarvesterUS$ 100 - 200MOQ: 1 Piece

-

YULONG Counter Flow Animal Feed Pellet CoolerUS$ 3,800 - 21,000MOQ: 1 Set

-

Electrical Motor and Diesel Hammer MillUS$ 870 - 870MOQ: 1 Set

-

Ring Die Pellet Mill Die Roller 300US$ 50 - 500MOQ: 5 Sets