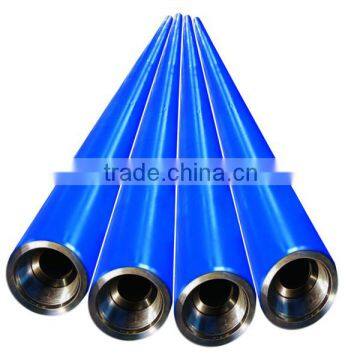

Chinese New Product API SPEC Drill Collar

Useage:

Drill collar is one of the most inportant elements of drill stem.It can provide drilling pressure of the bit and improve drill stem rigid.

Feature of product

Effectively control the trace element of the material which was selected with high quality and unique method. Adopt special intermediate frequency heat treatment method and advanced ultrasonic and magnetic particle inspection method and holding higher mechanical property. According to the shape and material dill collar was divided into three forms:

1. Type A (cylindrical): To be made of ordinary alloy steel, with circular cross section inside and outside the drill collar.

2. Type B (Spiral): To be made of ordinary alloy steel, with spiral grooves on the outer surface of drill collar.

3. Type C (Nonmagnetic): To be made of low magnetic permeability alloy steel,with circular cross section inside and outside the drill collar.

Drill collar Specifications

| Nominal size | OD | ID | L(mm) | Bevel Diameter(mm) | Bending Strength Ratio | ||

| mm | in | in | |||||

| NC31-41(2 7/8IF) | 104.8 | 4 1/8 | 50.8 | 2 | 9150 | 100.4 | 2.43:1 |

| NC35-47 | 120.7 | 4 3/4 | 50.8 | 2 | 9150 | 114.7 | 2.58:1 |

| NC38-50(3 1/2IF) | 127 | 5 | 57.2 | 2 1/4 | 9150 | 121 | 2.38:1 |

| NC44-60 | 152.4 | 6 | 57.2 | 2 1/4 | 9150 | 144.5 | 2.49:1 |

| NC44-60 | 152.4 | 6 | 71.4 | 2 13/16 | 9150/9450 | 144.5 | 2.84:1 |

| NC44-62 | 158.8 | 6 1/4 | 57.2 | 2 1/4 | 9150/9450 | 149.2 | 2.91:1 |

| NC46-62(4IF) | 158.8 | 6 1/4 | 71.4 | 2 13/16 | 9150/9450 | 150 | 2.63:1 |

| NC46-65(4IF) | 165.1 | 6 1/2 | 57.2 | 2 1/4 | 9150/9450 | 154.8 | 2.76:1 |

| NC46-65(4IF) | 165.1 | 6 1/2 | 71.4 | 2 13/16 | 9150/9450 | 154.8 | 3.05:1 |

| NC46-67(4IF) | 171.4 | 6 3/4 | 57.2 | 2 1/4 | 9150/9450 | 159.5 | 3.18:1 |

| NC50-67(4 1/2IF) | 171.4 | 6 3/4 | 71.4 | 2 13/16 | 9150/9450 | 159.5 | 2.37:1 |

| NC50-70(4 1/2IF) | 177.8 | 7 | 57.2 | 2 1/4 | 9150/9450 | 164.7 | 2.54:1 |

| NC50-70(4 1/2IF) | 177.8 | 7 | 71.4 | 2 13/16 | 9150/9450 | 164.7 | 2.37:1 |

| NC50-72(4 1/2IF) | 184.2 | 7 1/4 | 71.4 | 2 13/16 | 9150/9450 | 169.5 | 3.12:1 |

| NC56-77 | 196.8 | 7 3/4 | 71.4 | 2 13/16 | 9150/9450 | 185.3 | 2.70:1 |

| NC56-80 | 203.2 | 8 | 71.4 | 2 13/16 | 9150/9450 | 190.1 | 3.02:1 |

| 6 5/8REG | 209.6 | 8 1/4 | 71.4 | 2 13/16 | 9150/9450 | 195.7 | 2.93:1 |

| NC61-90 | 228.6 | 9 | 71.4 | 2 13/16 | 9150/9450 | 212.7 | 3.17:1 |

Workshop

Drill collar Processing Equipment

Drill collar production process charge

Certificate

International advanced manufacture facilities and production technology was adopted in our factory. We hold one advanced pipe-end upset line; one pipe heat treatment line; two friction welding lines with two sets of inertia friction welding machines made by MTI; one set of tubing and casing production line; one drill collar production line. The annual output of drill pipe reaches 50,000 tons; drill collar reachs 5000 pieces; various oil well pipes reach more than 100,000 tons.

Process flow is strictly controlled in accordance with the requirement of API Q1 quality management system. We establish a set of control system which includes raw material inspection control, production process flow control, products parameter control, semi-finished and finished products transfer control. We have equipped with the most advanced automatic ultrasonic testing, magnetic particle testing, and magnetic flux leakage testing equipment. Our physical chemistry laboratory has the most complete sets of physical and chemical quality testing equipment, including tensile testing machine, hardness testing machine, impact testing machine, and imported metallographic analysis inspection machine for chemical composition test.

We set special R & D center in our company and have strong teams with dozens of senior engineer, general engineer, senior technician and many skilled workers. Our experts focus their effort s on R & D of product performance and new material to make products be more resistant to torsion and sulfur. We are always insisting that survive by quality, develop by credibility. We have received the following certificates: AP1 Q1, API SPEC 5DP, API SPEC 5CT, API APEC 7-1, ISO/TS 29001, ISO 9001, ISO 14001, OHSAS 18001 and HSE standard certificates awarded by CNPC and Sinopec. Shandong mingzhu would work with our clients all over the world to create a better prospect of business.

We will continue to R & D to enhance production capacity with the growing good reputation in the petroleum equipment market. We shall satisfy you with good quality, favorable credit and satisfactory service by the first-class management, first-class talent, first-class equipment, first-class process, and first-class quality.

Exhibition and Cooperation

Send Inquiry to This Supplier

You May Also Like

-

HRC58-65 HRC60 Weld Overlay Wear Resistant Bimetallic PlateUS$ 299.69 - 299.69MOQ: 1 Square Meter

-

6805150 Tilt Cylinder Bushing for BobcatNegotiableMOQ: 1

-

Robot Hardware Accessories Manufacture Thickness≤0.35mmNegotiableMOQ: 1 Set

-

Sofa CoverNegotiableMOQ: 1 Meter

-

Custom CNC MachiningNegotiableMOQ: 1 Meter

-

Drilling Equipments Drilling Fluids Vacuum DegasserNegotiableMOQ: 1 Set

-

Good Quality Tungsten Carbide Button InsertsUS$ 1 - 5MOQ: 100 Pieces

-

Airless Truck Tire Solid Vehicle Tire 17.5-25 20.5-25 for Mining Machine PartsUS$ 16 - 200MOQ: 1 Piece

-

Ball Mill Plant Used Automatic Feeding Electromagnetic Vibrating FeederUS$ 650 - 800MOQ: 1 Set

-

Api Oil and Gas Christmas Tree, Wellhead and Christmas Tree/X-mas Tree for Oil Well ControlUS$ 3000.00 - 3000.00MOQ: 1 Set