Efficiency is critical in the fast-moving world of modern manufacturing. The ever-changing global business environment pushes companies to streamline production and optimize workflows. Enter ‘CNC horizontal machining centers,’ an engineering marvel that revolutionizes parts production. These advanced machines have swiftly become essential to modern manufacturing because they are engineered to provide precision, speed, and versatility. But what differentiates them from vertical machining centers, and how can they transform your production processes? This blog will focus on the key benefits of CNC horizontal machining centers, with special attention to their efficiency, cost-saving, and value-creating capabilities for businesses in different sectors. From industry veterans to those new to the world of machining solutions, this guide aims to highlight the potential of these high-performing machines. Get ready to learn how CNC horizontal machining can transform your operational outlook.

What is a Horizontal Machining Center?

Horizontal machining centers are CNC machines built with great precision. The spindle of each center is oriented horizontally, which means that the cutting tool approaches the workpiece laterally. This design facilitates machining on several sides of a piece at once. Horizontal machining centers are commonly used for high-volume production, parts with complex geometries, a higher stability value, enhanced cycle duration, and the capability to manage more massive workpieces.

Understanding the Basics of Horizontal Machining Centers

Horizontal machining centers are well-known for their accuracy, efficiency, and flexibility; therefore, they are critical in the contemporary manufacturing environment. It most often features a horizontal spindle arrangement whereby the spinning tool can approach the workpiece from many angles, providing it easier accessibility, particularly for intricate 3D shapes. The following are some of their features:

Incrementing productivity: Their first and foremost advantage is enhanced efficiency. HMCs can execute numerous procedures in a singular setup without repetitive repositioning of the workpiece. This is made possible by using rotary tables or pallet systems, which improve the process flow and reduce cycle time. Research shows that HMCs can offer up to 40 Percent more productivity in large batch production than vertical machining centers.

Improved chip removal: Designed horizontally, it allows for natural chip removal, which improves tool life and machining accuracy. Chip removal is necessary and advantageous when machining ferrous and non-ferrous metals for long durations.

Strength and Load Bearing: Due to their HMC construction, they are ideal for more extensive and heavier workpieces. The latest models feature work tables that withstand loads above 1,000 kilograms during stable high-speed machining.

High Accuracy and Integration of Automation: Modern HMCs incorporate technologies such as tool changers, probing systems, and robotic interfaces, achieving unmatched accuracy and repeatability. Manufacturers can now achieve tolerances within microns, fulfilling the intricate requirements of aerospace, automotive, and medical device industries.

HMCs also have reduced operational costs because of increased material removal rates, less downtime, and decreased labor expenses. Although the initial investment in an HMC is higher than that of other machining centers, the long-term value often exceeds the cost.

Incorporating these features allows horizontal machining centers to enhance productivity while significantly sustaining high-quality benchmarks in stringent industries. The latest HMC models integrated with innovative manufacturing technologies and IoT exemplify the HMC’s role in the evolution of manufacturing.

How Do CNC Horizontal Machining Centers Differ from Vertical Machining Centers?

HMCs and VMCs differ in spindle orientation, versatility, and applications. The spindle on horizontal machining centers is oriented horizontally, allowing cutting tools to approach the workpiece from the side. This makes HMCs efficient with bulky parts because they can be heavy and deep. Also, HMCs permit chip evacuation because of gravity-driven downward chip flow. Vertical machining centers have vertically oriented spindles, making VMCs better for lighter and more compact parts.

Strategic advantages of HMCs include accommodating larger workpieces, multi-face machining, and a single setup. All of these factors significantly reduce repositioning and tool change time. Studies suggest manufacturing cycle times can be reduced by 25-30% with HMCs compared to VMCs for high production workflows. Many HMCs are equipped with pallet changers, which enhances productivity because operators can unload and load parts while the machine operates.

Conversely, VMCs benefit low-volume production businesses or need individual prototyping parts. They offer cost advantages for companies with limited space since they have a smaller footprint and simplified setups. Nevertheless, VMCs may have difficulties with chip evacuation within deeper or more intricate cavities, which may impact surface finish and tool life.

Ultimately, the choice between HMCs and VMCs is determined by the size of the components, the intricacy of machining operations, and the production volume. The two types of machines are invaluable to many industries, including automotive, aerospace, and medical device manufacturing, and they have become even more capable with the rise of automation and innovative technologies.

The Evolution of Horizontal CNC Machines

Since their emergence, the development of horizontal CNC machines has evolved dramatically, further advancing the precision, efficiency, and flexibility of manufacturing processes. Early horizontal machining centers were mainly suited for mass production of simple components, but modern horizontal machining centers can now effortlessly handle intricate geometries and demanding materials.

A significant step in their development is the introduction of multi-axis features. Modern machines often include 4-axis- or 5-axis machining, significantly improving flexibility and allowing more complex parts to be manufactured in one setup. This feature has greatly benefitted the aerospace and automotive industries by reducing setup time and increasing efficiency.

Another significant development is the introduction of automation. Horizontal CNC machines are often used with pallet changers, robotic arms, and advanced tools management systems for continuous operation. This automation method targets the ever-increasing need for high production rates with minimal downtime. For example, automated systems are proven to enhance machine utilization by 80%, depending on the specific automated setup.

Integrating innovative technologies and the Industrial Internet of Things (IoT) has lifted horizontal CNC (Computer Numerical Control) machining to even greater heights. Adding real-time monitoring, predictive maintenance, and artificial intelligence (AI) programming further improves machine efficiency, reducing costs. One study from 2022 found that manufacturers with innovative CNC systems reported as much as 25% reduction in unplanned downtimes.

Such advancements are in line with the rising focus on sustaining the environment. Modern horizontal CNC machines are designed to reduce energy consumption while strategically using materials to minimize waste and carbon footprint.

Together, the development of horizontal CNC machines demonstrates the fantastic progress in machining technology and how important they are for advancing manufacturing industries worldwide. The ongoing development of these machines strengthens their value as tools in the precision and efficiency-driven world.

How to Choose the Right Machine Tool?

Selecting any machine tool is a process that involves understanding your prerequisites thoroughly. First, define the types of materials you will be working on and what specific machining operations like cutting, drilling, or milling will be required. Determine the accuracy level and the production volume, establishing whether a high-speed or heavy-duty machine is appropriate. Also, consider the dimensions of the available workspace. Other important considerations are its dependability, how simple it is to service, the amount of energy needed to operate it, and its efficiency. Lastly, prioritize businesses that manufacture quality products like customer support, warranty, and proven lasting dependability and performance, claiming a trustworthy position in the market. Expand on the entire supplied answer.

Key Features to Look for in a CNC Horizontal Machining Center

Spindle Speed and Power: The accuracy and performance of machining operations greatly depend on the spindle. Most CNC horizontal machining centers have spindles capable of 10,000 to 20,000 RPM and 50 to over 100 HP power. Balance spindle selection with your material and application requirements, as greater power and speed enhance cutting efficiency, notably with more rigid materials such as titanium or hardened steel.

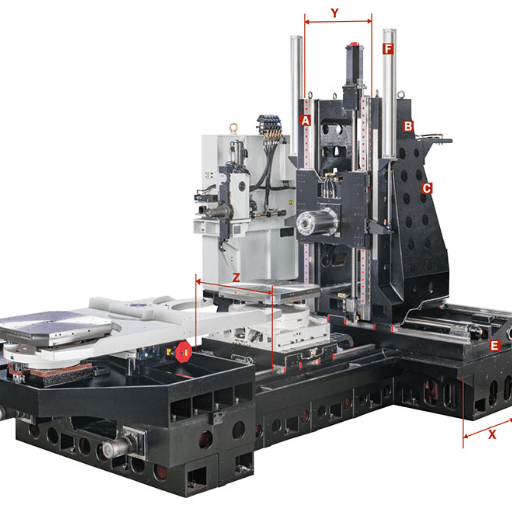

Axis Travel and Work Envelope: A machining center’s work envelope defines its capability for specific part sizes and shapes. Search for further extended travel in the X, Y, and Z axes—many advanced centers offer at least one travel over 1,000 mm. This benefit enhances precision when working on more significant parts because the need for repositioning is eliminated.

Tool Capacity and Magazine Type: For high-variety, low-volume production systems, select a machine with an expansive tool magazine. Advanced models offer 60—to 200-tool capacity options alongside automated tool retrieval systems. Some are equipped with dual-arm tool changers, improving cycle times and ensuring operational efficiency and uninterruptible, steady workflow.

Precision and Thermal Stability Technologies: Accuracy is vital in aerospace and medical applications. Advanced CNC machines include thermal control, precision encoders, and linear scales, which mitigate environmental and operational heating. These features reduce the inaccuracy caused by thermal expansion to ensure constant operational tolerance accuracy even during extended production run cycles.

Automation and Pallet Systems: Modern machining centers are increasingly fitted with multi-pallet systems and robotic automation. Multi-pallets improve productivity by allowing continuous work by automatically swapping workpieces. When paired with robotic arms for loading and unloading, manufacturers can achieve lights-out machining with little operator interaction.

High-Quality Construction and Rigidity: A machine’s material affects its construction quality. Cast iron or Meehanite increases vibration dampening and structural stability. Rigidity is critical during high-speed cutting operations to maintain the spatial accuracy needed while improving the tool’s lifespan and minimizing the chances of workpiece error.

Control System and Connectivity: Complex and fluid operations rely on robust control systems, including those from FANUC, Siemens, and Mitsubishi. Remote monitoring and data analytics greatly enhance real-time machine performance tracking and uptime maximization. Modern CNC horizontal machining centers also have IoT connectivity and offer industry 4.0 technology compatibility.

Energy Sustainability and Efficiency: Sustainable development is becoming a significant daily concern. Newer machine designs aim to alleviate environmental impacts, including energy spindle motors, regenerative braking, and lower pneumatic demand as a prerequisite standard. These advancements will sustain air production and maintenance operations without any shift in output quality.

Addressing these strategic attributes using sophisticated technological methods, producers still have the option to choose the right CNC horizontal machining centers, which will fulfill their individual production needs and improve organizational productivity, accuracy, and profit margins.

Comparing 5-Axis Horizontal Machining Centers

The following aspects stand out when deciding which 5-axis horizontal machining centers to go with due to their impact on decision-making. Due to their unrivaled capabilities in simultaneous multi-axis operations, these machines offer the best value when used in highly complex and precise industries. The following is the most critical consideration when making comparisons between these sophisticated machining instruments:

Precision and Accuracy: Among the many machining operations, 5-axis horizontal machining centers stand out because they can be operated accurately and precisely. In some cases, the precision achieved by these devices is as good as ±0.0001 inches. Sophisticated control systems like FANUC or Siemens and other analogous controllers assure dependable and repeatable performance, irrespective of the complexities involved. The most sophisticated geometrical shapes perform with repeatable precision.

Work Envelope and Table Capacity: Different machine models differ significantly in the size of the work envelope and the rotary capabilities of the table. For example, rotary tables on some machines can accommodate workpieces with diameters as large as 1000 mm and masses exceeding 1500 kg. Such versatility allows enterprises to handle more significant, complicated parts in the automotive and aerospace industries.

Spindle Speed and Power: Modern 5-axis horizontal machining centers offer high-speed spindles ranging from 10,000 to 30,000 RPM, depending on the application. Machines with direct-drive spindles achieve smoother overall operations and have reduced vibrations, which is critical for high-precision machining. In addition, spindle power is often more than fifty horsepower for processes with more rigid materials like titanium and steel alloys.

Automation and Integration: These machines integrate automation solutions such as pallet systems and robotic arms in single-piece flow production cycles. Integrated tool changers with over one hundred tools for efficient productivity automate foreseen and unforeseen downtimes. Most models also support Industry 4.0 standards of real-time tracking and predictive maintenance.

Energy Efficiency and Environmental Considerations: Manufacturers are addressing sustainability aspects of 5-axis machining centers. Economic motors, rationalized coolant supply, and regenerative braking energy recuperation lower operational costs without throttling the machine’s performance. Some reports claim these models achieve over thirty percent relative to previous generations.

Industry-Specific Examples: Due to stringent tolerances and high surface quality requirements, the aerospace industry frequently uses 5-axis machining centers, particularly for turbine blades and structural components. On the other hand, automotive manufacturers use these for lightweight, strength-demanding components like engine blocks and suspension components.

Through careful analysis of these attributes, manufacturers and operators can select the 5-axis Horizontal Machining Centers that meet their production objectives and gain a competitive edge in precision, efficiency, and cost-effectiveness.

Factors to Consider for Precision Machining

Selection of Materials: In precision machining, the choice of material is essential. Some materials, such as titanium, high-performance alloys, and hardened steels, are used due to their strength and wear resistance. For example, titanium is used in aerospace and medical industries because of its strength-to-weight ratio and biocompatibility. The material’s machinability (capability of being worked on, thermal properties, and tensile strength should be known for precise results.

Tooling and Cutting Parameters: The cutting tools used and how they are set, such as the feed rate and spindle speed, also affect the machining accuracy, so care should be taken. For example, Carbide or diamond-coated tools significantly increase wear resistance and life of the tools used in rough and challenging jobs, so they are an advancement in tooling technology. Some research has shown that cutting tool parameters have increased the cycle time to 30% while keeping the component quality the same.

Machine Accuracy and Stability: The equipment and machine used in the process should also be stable and accurate for proper precision machining. Thermal stability, how the machine shakes, and how rigid the spindle is will all affect the tolerances possible. Machines with good thermal compensation features and rigid structures will achieve good precision even running at high speeds (high RPMs), giving good results. Benchmarks from the industry suggest the latest 5-axis horizontal machining centers can achieve ± 0.002 inches on intricate geometries.

Software and Automation: Precision enhancement heavily relies on CNC programming and sophisticated software. Modern machining centers with CAD/CAM software allow simulation, optimization, and error mitigation before production. Automation technologies, such as robotic loading systems and adaptive control, enhance consistency and efficiency, reducing human error. In some sectors, productivity is boosted by 25% due to these innovations.

Coolant and Lubrication Systems: Effective cooling and lubrication preserve tool life and surface integrity. Advanced coolant delivery methods, such as high-pressure or through-spindle cooling, greatly enhance the performance of modern tools. These methods assist in preventing thermal distortion, maintaining dimensional stability, and reducing tool wear.

Inspection and Quality Control: The very basis of precision machining relies on strict quality control processes. Industrial metrology has evolved with the development of CMMs and laser scanners, which enable the verification of products against defined tolerances. Specific industries, especially aerospace, require 100% inspection for critical components, while automated inspection enhances throughput without compromising precision.

Strategically tackling these highlighted matters helps manufacturers achieve unrivaled precision in techniques and processes tailored to industry-specific standards while optimizing production efficiency.

What are the Benefits of Horizontal CNC Milling Machines?

Horizontal CNC milling machines yield improved productivity and flexibility for different manufacturing processes. They are particularly appreciated for their ability to handle large and heavy workpieces due to their robust construction and horizontal spindle arrangement. These machines enhance productivity by reducing heat buildup, tool wear, and chip removal during machining, ensuring long, uninterrupted production runs. Likewise, they allow multi-sided machining in a single setup, thereby minimizing production time and increasing precision. Their rigid construction dampens vibrations, improving surface finishes and prolonging tool life, making them ideal for complex machining and high-volume manufacturing.

Boosting Productivity with Horizontal Machines

Horizontal machining centers (HMCs) are now a predominant piece of equipment in the manufacturing industry because of their versatility and efficiency. One of the most important benefits is that they can handle large-scale production requirements while achieving high levels of accuracy. Recent developments in technology and tooling have further improved their performance. For example, HMCs can reduce cycle time by 25 to 30 percent compared to vertical machines due to rapid tool changes and multi-sided machining.

Also, when machining rigid or high-volume materials, horizontal spindle orientation improves chip evacuation and reduces tool wear, heat, and downtime, enhancing tool life. In addition, HMCs dramatically improve the quality of surface finishes and repeatable accuracy needed for complex geometric shapes in the aerospace and automotive industries.

HMCs’ seamless integration with automation tools such as pallet changers and robotics enables other productivity improvements and facilitates lights-out manufacturing, drastically increasing output while decreasing labor costs. The advanced durability and innovations, coupled with improved compatibility with innovative manufacturing systems, make horizontal machining centers crucial for companies striving to remain relevant in today’s rapidly evolving manufacturing landscape.

Advantages of Automation in Horizontal CNC

Horizontal CNC system automation offers considerable advantages concerning the new trends in the competitive environment of modern manufacturing. One of the primary advantages is the boost in productivity. Research indicates that automated horizontal machining centers (HMCs) can improve efficiency by up to 30% because they minimize downtime and allow for nonstop operations such as lights-out manufacturing.

Another advantage is greater precision and accuracy. Horizontal CNC machines can manufacture complex components with minimum human interaction, using robotics and automation to diminish the likelihood of human error. This ensures high-quality production standards during sustained production cycles.

Cost-effectiveness is also essential in this scenario. Investing in automation might seem expensive, but in the long run, the reduction in labor costs and acceleration in production delivers a dramatic ROI. For example, HMCs with automation are said to reduce operational costs by 15–20% over time due to a decrease in wastage, streamlined operational flows, and better materials utilization. In addition, contemporary automation systems have incorporated AI analytics and real-time monitoring, enabling manufacturers to track performance and anticipate maintenance needs. Predictive maintenance alone can reduce downtime by 50%, guaranteeing continued production and improving efficiency.

With the advanced technology integration and automation frameworks, horizontal CNC machining centers allow manufacturers to respond to growing needs while ensuring cost-effectiveness, reliability, and quality.

How Do Tool Changers Improve Efficiency?

Changeover tools increase efficiency by reducing downtime in the machining process. Tool changers enhance automation by allowing automatic tool swaps, thus minimizing the time spent on manual tool changeovers. Automation ensures that machines run for extended periods without having to stop. They also automatically improve precision through the tools’ repeatable, relative, axiomatic positioning, resulting in lower error rates and enhanced productivity. Manufacturers can shorten production cycle times and operational efficiency through optimized tool change procedures.

The Role of ATC in Modern Machine Shops

The introduction of Automatic Tool Changers (ATC) into contemporary machine shops is a clear testimony to their effectiveness in improving the operational flexibility and efficiency of the shop. ATCs and advancements in the CNC frameworks allow machines to perform various tasks automatically without any manual intervention. For example, a modern CNC machine with an ATC can hold more than 120 tools and can interchange tools automatically as per the requirements of the different stages of complex projects. This feature of ATCs reduces downtime remarkably, which studies claim is as high as 40% in idle time in manual tool changes.

ATCs provide a competitive advantage over time; cost advantage is equally essential. Estimations reveal a cost efficiency resulting from the increase in the ATC system’s tool change speed, reduction in the time needed for rework, and decreased cost of materials due to the precision of systems and efficient production. Moreover, better ATC supports other manufacturing processes, like 5-axis machining, which requires fast and exact tool changes because of complicated parts.

The use of ATCs has further enhanced machine shop safety. With ATC automation, the risks of manual tool changes are significantly reduced, as operators no longer have to be physically present to perform tool changes. Moreover, the consistent placement of tools contributes to considerable improvement in the accuracy and quality of the production process.

The incorporation of innovative technologies like sensors and data analytics has improved the roles played by ATC systems even further. Predictive technology that anticipates tool wear and optimizes tool usage may reduce tools’ associated and operational costs while ensuring peak performance. Overall, the integration of ATC in industrial and small-scale manufacturing reinforces the importance of ATC technology in maintaining modern machine shops’ competitiveness and efficiency.

Enhancing Spindle Speed and Axis Travel

In modern machining, there is an emphasis on increasing spindle speed, and the rate of axis travel to fulfill the requirements of high precision and efficiency manufacturing. The speed of the spindle now exceeds 20,000 RPMS in advanced CNC machines. This improvement permits smoother finishes and increased productivity when dealing with complex erosive materials such as titanium and composites. Moreover, optimizing the axis travel improves the working range of the machine tool in the x, y, and z directions. Productivity and flexibility with larger, more complex workpieces can also be achieved. Some high-performance models currently have increased axis ranges of over 1,200 millimeters, which allow accurate machining of large parts for precise aircraft, automobile, or energy components.

To advance these technologies, manufacturers are adding sophisticated motion controls and linear drive systems that further boost acceleration and deceleration rates, minimizing cycle times and energy used. Industry studies show that these machines with enhanced spindle speed and greater axis travel significantly reduce operational efficiency by upwards of thirty-five percent while also minimizing material waste. This is in tandem with the need for flexible and modular systems that broaden the scope of responsive machining and enable swift adaptation to changing technological and market requirements.

What Industries Benefit from Horizontal Machining Centers?

Due to their versatility, horizontal machining centers are advantageous to many industries. They are economically essential for the automotive industry to engine parts and transmission components, aerospace for high-precision structural and turbine components, and the medical field for manufacturing surgical tools and implants. In addition, these machines are essential in the oil and gas sector, heavy equipment manufacturing, and general commercial manufacturing for precise and intricate mass production. Their role in precise, high-volume workloads makes them indispensable, where stringent standards and high productivity are mandatory.

Applications of HMCs in Aerospace

In the aerospace industry, Horizontal Machining Centers (HMCs) assist in crafting delicate components needed in aircraft, spacecraft, and other aviation systems with great precision and efficiency. Their unmatched capabilities make them perfect for machining materials within the aerospace industry, which requires exceptional tolerance and material machinability. Moreover, titanium and aluminum alloys, often used in the aerospace industry because of their strength-to-weight ratio, are expertly machined with HMCs.

One aerospace application where HMCs are critical is manufacturing the structural elements of an aircraft, such as wing spars, fuselage frames, and landing gear assemblies. These parts are safety-critical and high-precision, making HMCs a perfect fit to ensure accuracy. Moreover, HMCs are utilized to produce turbine blades for aircraft engines. The components must be designed and manufactured with intricate features and smooth surfaces to the best possible standard to maximize aerodynamics, heat resistance, and efficiency.

Multi-axis HMCs significantly improve productivity and operational costs when coupled with automation systems. The HMCs allow for the completion of complex geometries in one single setup, considerably reducing the time and effort spent on rework. With the sensitive cost factors in the aerospace industry, these advantages are crucial.

Reports from different industries emphasize the accelerating integration of HMCs in aerospace, spurred by the growing need for lightweight aircraft and fuel-efficient technologies. These drivers further prove HMC’s significance as a powerful means to sustain a competitive edge and adapt to ever-changing industry demands.

The Impact on the Automotive Sector

Horizontal machining centers (HMCs) have transformed the automotive industry by improving its manufacturing process’s precision, efficiency, and scalability. As the demand skyrockets for electric vehicles (EVs) and autonomous driving technologies evolve, the automotive sector now more than ever requires high-performance machining equipment to adhere to stringent production requirements. HMCs aid in fabricating complex parts, such as lightweight chassis and sophisticated engine components, with unmatched precision and in remarkably short times.

Recent industry data shows that the worldwide automotive machining market is estimated to grow significantly in the following years because of the increasing EV production and the demand for lightweight constituents to enhance fuel efficiency. For example, there has been a sharp increase in the usage of aluminum and composite parts, which need to be machined with precision and reliability, which only HMCs can offer. Furthermore, HMCs enhance productivity due to reduced material waste, an invaluable advantage as manufacturers focus on resource optimization to maintain competitiveness.

Today, HMCs enable automotive manufacturers to optimize workflows and streamline quality control processes by integrating intelligent automation technologies alongside real-time monitoring systems. This is especially important for the safety and reliability of various vital automotive components. The developments in these areas place HMCs as a cornerstone in the advancing automotive industry, allowing manufacturers to respond to the challenges of innovation and sustainability.

Case Studies from Modern Machine Shops

Through the integration of predictive maintenance with AI analytics, a renowned automobile manufacturer was able to optimize the operational workflows of its horizontal machining centers (HMC) to a remarkable degree. Predictive maintenance empowered the company to foresee machine failures utilizing AI analytics and advanced sensors, resulting in a 30% reduction in unscheduled downtime. This method also delayed replacing important parts, reducing maintenance expenditure by 20% during the year. Better uptime also increased overall production capacity by 15%, improving responsiveness to market demands.

Case Study: Sustainable Manufacturing through Adaptive Machining

A precision engineering firm adopted adaptive machining practices by implementing real-time monitoring and advanced control algorithms in HMCs. This led to improvements that were aligned with sustainability objectives concerning material and energy consumption. The firm reported a 25% reduction in material waste due to more efficient cutting and lower rework rates. Additionally, energy consumption per unit was reduced by about 18%, directly contributing to a smaller carbon footprint. These operational improvements enhanced the company’s profitability while simultaneously meeting increasing environmental compliance requirements.

Case Study: Improving Quality With Automated Inspection Systems

A company focused on high-precision aerospace components also encountered a prominent case with automated in-machine inspection systems, which incorporate laser scanning and high-resolution imaging to check geometries while parts are still in the HMC. The improvements brought unprecedented results, decreasing the proportion of defective components by almost 40% and increasing customer satisfaction. Moreover, the implementation streamlined quality assurance workflows, resulting in a 10% faster delivery cycle, making the business more competitive in a highly dynamic environment.

These case studies demonstrate the potential of HMCs to fundamentally transform manufacturing in various sectors by enhancing operational productivity, green compliance, and product excellence.

This shows how industry leaders are adopting new technologies and devising new strategies to keep up with changes in the industrial landscape.

Reference Sources

I’ve gathered and reviewed several recent studies related to horizontal machining centers. Here’s a summary of their key findings and methodologies:

-

Dynamic Performance Analysis and Optimization5:

Key Findings: This study’s analysis and optimization method for horizontal machining centers is based on applying contact theory. The study optimized sensitive parameters of some weak parts, discovering enhanced improvements in modal flexibility alongside natural frequencies. For example, the first natural frequency was improved by 26.64%.

Methodology: The study used static flexibility analysis, modal flexibility evaluation, potential energy distribution assessment, and experimental validation to evaluate the proposed contact stiffness models.

-

Improved Measuring Device for Free Form Surfaces2:

Key Findings: The study further developed a self-measuring device meant for the free-form surfaces of machining centers. A new sensing method, an AC servo motor for improved motion, and a laser displacement detector with an extended scope of use were added. These modifications increased the accuracy and efficiency of measurements obtained.

Methodology: The verification testing performed on the other materials was sufficient to demonstrate the device’s practical performance, thus confirming its effectiveness in the benchmark.

-

Tool-to-Workpiece Vibrations During Chatter Development3:

Key Findings: This research looked into chatter and the accompanying oscillation or vibration in a milling spindle. It determined that velocity measurements are reliable markers of chatters’ progression since they depict tool and workpiece vibrations.

Methodology: The research utilized inductive sensors and accelerometers to capture vibrational data and perform frequency analyses to determine and isolate frequencies associated with chatter.

The research contributes to developing horizontal machining centers’ productivity, measurement precision, and operational stability.

Frequently Asked Questions (FAQs)

Q: What are CNC Horizontal Machining Centers?

A: CNC Horizontal Machining Centers are advanced machine tools that utilize a horizontal orientation to perform high-precision machining. These centers are numerically controlled and are renowned for their efficiency and accuracy in large production runs.

Q: How do CNC Horizontal Machining Centers differ from vertical ones?

A: The key difference lies in the spindle orientation. Horizontal machining centers have a horizontal orientation, which allows chips to fall away from the workpiece, improving part quality. This contrasts with vertical machining centers (VMC), where the spindle is vertically oriented.

Q: What are the benefits of using a pallet in CNC Horizontal Machining Centers?

A: Pallets in CNC Horizontal Machining Centers streamline the machining process by allowing for quick pallet changing. This setup reduces downtime and enhances efficiency and accuracy during production.

Q: Why is high torque important in horizontal milling?

A: High torque is crucial for horizontal milling. It enables the machine to handle heavy-duty cutting operations quickly and precisely, ensuring consistent accuracy and precision in machining tasks.

Q: What should I consider when finding the right machine for my needs?

A: When finding the right machine, consider factors such as pallet size, the complexity of the parts, torque requirements, and whether you need 3-axis, 4-axis, or b-axis capabilities for your specific machining solutions.

Q: How do horizontal machining centers deliver efficiency and accuracy?

A: Horizontal machining centers deliver efficiency and accuracy through advanced design, allowing optimal tool access and precise control over the machining process. Their ability to handle complex parts and large production runs adds to their effectiveness.

Q: What is the advantage of using a b-axis in horizontal machining?

A: The b axis in horizontal machining provides enhanced flexibility by allowing the spindle to rotate around a horizontal axis. This enables complex angle cuts and improves the versatility of the machining process.

Q: Can CNC Horizontal Machining Centers handle horizontal and vertical machining tasks?

A: While CNC Horizontal Machining Centers are optimized for horizontal milling, many models can also perform vertical tasks, making them versatile for various machining requirements.

Q: Why might CNC Horizontal Machining Centers come with a higher price tag?

A: CNC Horizontal Machining Centers often have a higher price tag due to their advanced features, such as pallet changing systems, high torque capabilities, and the ability to perform complex machining with high precision, ultimately enhancing part quality.

Q: How do these machining centers manage tool access and chip removal?

A: CNC Horizontal Machining Centers are designed to provide optimal tool access for efficient machining. Their horizontal orientation allows chips to fall away from the workpiece naturally, reducing the risk of re-cutting and improving overall machining quality.