Every person using or planning to use LEDs must have encountered the term ‘LED driver’ at least once. It is an essential part of any LED lighting system, but why it matters has often been ignored. In truth, LED drivers are necessary for any LED system’s efficiency, life, and operation. Instead, integrating LED technology in any personal or professional lighting design requires knowledge of LED drivers and, thus, unraveling the mysteries surrounding them. The drivers provide the essential tools in the constellation to make modern lighting systems functional and reliable. This guide will discuss LED drivers’ significant components and their respective functions. Subsequently, the required information will be provided regarding the scope and boundaries of the operational usefulness of a respectful LED driver.

What is an LED Driver and How Does it Work?

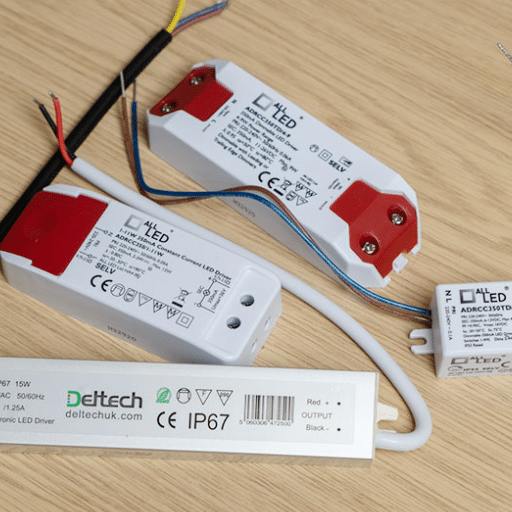

An LED driver manages the energy given to an LED or a collection of LEDs. Since LEDs need precise current levels to function well and avoid harm, the driver converts energy from the source (such as mains electricity) to ensure proper voltage and current. An LED without a driver can suffer from power surges which can cripple their performance. In basic terms, the LED driver protects the LEDs from malfunctioning by ensuring consistent performance.

Understanding LED Driver Functionality

Numerous elements fundamentally determine the efficiency, reliability, and integration of the driver LED systems, which influence the functionality of an LED driver. The foremost concern is power efficiency—most contemporary LED drivers have power efficiencies above 85%, which reduces performance degradation associated with energy loss. Current regulation capability is also significant; drivers must supply constant current to avoid brightness inconsistency and overheating damage. An example would include high-quality LED drivers that support current fluctuation tolerances (supported) of as low as ±1%, contributing to lighting output consistency.

Additional features include the ability to implement some form of dimming, the most basic of which is a simple CCR (Constant Current Reduction). More advanced drivers are capable of PWM (Pulse-Width Modulation) dimming. Analysis of chronicled driver specifications indicates that commercialized products boast PWM dimming (with) a dynamic range for some d limited to 1% to 100%, which can benefit both residential and commercial facilities (optimal). In addition, these drivers are also compliant with surge protection regulations, making them resilient to voltage spikes (4kv), which are common in many industrial models.

Incorporating these features enhances the longevity of LED lighting systems, and using the driver becomes vital for energy-efficient lighting systems.

The Role of Power Supply in LED Lighting

LED lighting systems are powered only once the required current and voltage is supplied, making the power supply the system’s most critical component. The LEDs themselves require low-voltage direct current (DC) to operate; therefore, the power supply transforms the high-voltage alternating current (AC) obtained from the mains power into usable energy. If the power supply unit is faulty or poorly designed, the LEDs will light flicker, produce inconsistent light output, or experience premature failures.

Manufacturers were concerned about the earlier issues, but now they aim to improve power supplies’ dependability and efficiency. Achieved data suggests that most modern power supplies for LED lights now enable energy conversion of over 90%, considerably shrinking energy waste and operational costs. In addition, many power supplies now offer intelligent systems in dimming controls and overload protection, allowing greater customization and protection from electrical hazards.

Heat management is also an essential aspect of LED power supplies. Excessive heat degrades an LED’s performance. Quality power supplies incorporate thermal management features like thermal shutdown to mitigate overheating and improve the longevity of LED systems. For example, industrial LED solutions frequently use power supplies designed to operate from -40°C to 85°C and thus specialize in extreme environment functionality.

Industry trends also emphasize the growing use of programmable power supplies. These newer constructions allow remote changes and real-time checking, thus improving convenience and efficiency for residential and commercial uses. Reliable power supplies are, therefore, necessary for improving conservation efforts and protecting the sustainability of LED technologies.

Decoding the Output Voltage of LED Drivers

The output voltage of LED drivers is one of the specifications that define compatibility with various LED modules. LED drivers are supposed to operate in a given range, usually within the forward voltage bounds of the LEDs. For example, a single white LED’s forward voltage is generally between 2.8V and 3.3V. Multi-LED arrays may require considerably higher voltages.

These days, LED drivers have constant voltage (CV) and constant current (CC) as the two main categories of output voltage. Constant voltage drivers are designed to give out a particular voltage value, like the standard 12V or 24V, which are suitable for LED strips where each LED has a resistor or driver. While constant current CC drivers maintain a certain current, they change the output voltage to suit the requirements of the LEDs connected to the driver.

The interaction of output voltage and power efficiency is also significant. When the output voltage of the LED driver is equal to or very close to the LED module’s forward voltage, energy losses will be at a minimum, and so will efficiency losses. On the other hand, too much variation in output voltage may cause additional thermal buildup, which, in extreme cases, will reduce the lifespan of the LEDs.

Recent developments in programmable LED drivers allow for flexible adjustments with dynamic range output scaling. For example, some drivers can operate across a wide voltage range, 10V to 54V so that they can be used for different lighting configurations. This flexibility is beneficial for mixed or changing LED configurations.

Considering the output voltage of LED drivers also assists in meeting electrical safety standards. Ensuring the voltage does not exceed the LED module’s maximum tolerance is crucial to avoid overheating and subsequent damage. The detailed specifications manufacturers provide help users make the right choice regarding the driver and other specific requirements.

How do you select the right LED driver power supply for your needs?

Selecting the ideal LED driver power supply requires consideration of several key parameters. First, check if the power requirements are suitable, including the voltage and current for the LED fixture and if it works with the driver. Power specifications are defined in the LED documentation and must be checked. Second, check the type of LED lighting being utilized to know the kind of driver; constant current and constant voltage LEDs use different drivers. Third, check if the driver’s power is above the total power consumption of the LEDs; if so, for optimal performance, choose a driver with a little more power than needed to achieve the best results. In addition, environmental conditions must be considered, and the LED driver should be checked to determine where it will be used. The driver should have adequate waterproofing and an appropriate IP rating for outdoor and damp areas. Lastly, mark it down if the driver allows for dimming and is compatible with the dimming system. If the driver is known to support dimming, that capability should also be checked.

Meeting these requirements with personal needs will result in a dependable LED driver power supply.

Factors in Selecting an LED Driver

Using additional information ensures selecting an LED driver that performs best for your use case. Below are some key aspects that should help in making a more informed selection:

Efficiency Ratings: Efficiency is one of the most important factors relevant to the functioning of LED drivers. Most models operate at over 90% efficiency, meaning energy loss and operational costs will be much lower. Increased efficiency also means less energy is consumed in heat, increasing the driver’s operational life and associated LEDs.

Power Factor (PF): A high power factor is a positive sign, and the LED driver should always be above 0.9 to be effective. A high PF indicates that the electricity used is used effectively without any wastage. This is important in larger installations because energy consumption can significantly increase operational costs.

Thermal Management: Overheating can degrade components of several devices to shorten their lifespan. Look for Drivers that have over-temperature protection features. Such mechanisms can overheat components and reduce the lifespan of the device. Advanced LED drivers are designed with superior thermal management features that help maintain safe operating temperature ranges.

Current and Voltage Regulation: Stringent control of current and voltage prevents LEDs from receiving power inconsistently, which can cause flickering or premature wear. High-end or delicate lighting systems are usually equipped with constant current drivers due to the accuracy and stability required to ensure optimal performance.

Flicker-Free Operations: Flicker-free drivers are essential in healthcare, workplaces, and photography environments. Most contemporary drivers now follow international standards because they provide steady illumination, which decreases eye strain and enhances comfort.

Certifications and Compliance: LED drivers must pass safety and performance checks to be certified by UL, CE, or FCC. Following these regulations ensures product credibility and allows them to be used in specific industries and regions.

Longevity and MTBF: Most manufacturers provide MTBF (Mean Time Between Failures), a standard related to the expected lifespan of the driver. High-quality drivers accompany an MTBF of over 50,000 hours, proving more economical.

Adaptive Technologies: Adding adaptive technologies such as programmable output currents or IoT Incorporation of the Internet of Things makes these drivers some of the newest, allowing for more innovative and flexible systems. These are incredibly beneficial to ever-changing settings like commercial and intelligent automation systems.

Every application differs, so considering the correct LED driver involves checking all of these technical aspects and your application’s requirements or needs. Understanding these components promotes optimal operational efficiency, reduced maintenance strain, and enhanced system lifespan.

Comparing Constant Voltage vs. Constant Current Drivers

Selecting the appropriate LED driver for your system requires understanding the difference between constant voltage and current drivers. While both are crucial components of any LED lighting system, their functionality and application areas are distinct.

Constant Voltage Drivers allow current to vary freely depending on the connected load while consistently delivering output voltage measures of 12V or 24V. These drivers find vast applications where LEDs operate in parallel configurations, like with LED strips or in systems where the LEDs are pre-current regulated. Signage and decorative lighting are other examples of constant voltage applications, as steady voltage helps ensure uniform component brightness. Their ease of installation further lends them to systems with low regulatory needs and complexity.

On the other hand, Constant Current Drivers maintain a steady current while the voltage changes according to the LED’s characteristics. This type of driver is usually described in terms of milliampere, for example, 350mA or 700mA, and is designed to supply current to LEDs (light emitting diodes) connected in series. Since LEDs require a well-defined current to work efficiently without thermal runaway, constant current drivers are used for high-power LED lighting such as downlights, spotlights, or other professional-grade luminaires. Research indicates that continuous current drivers can enhance the maximum output and longevity of LEDs by controlling overheating and avoiding overdriving.

Efficiency Comparison: Constant voltage drivers are less specialized than their constant current counterparts but can be inefficient because they consume excess energy while powering LEDs at different currents. Conversely, constant current drivers optimize energy use while relieving thermal issues, which is ideal for sensitive energy projects.

When choosing between the two, it is essential to evaluate the design of the LED system, its power needs, and performance benchmarks to select the relevant driver type for reliable performance and efficiency.

Understanding 24V and 12V Options

Understanding different advantages and application areas is extremely important when choosing between 24V and 12V options for your LED systems. A 12V system is often used for smaller installations with short cable runs because it is easier to use and cheaper. However, it can be inefficient in preventing voltage drops over long distances and unequal brightness among some LEDs.

A 24V system is preferable for larger projects with longer cable runs because of its excellent power handling and better energy distribution. Al1 24V setup usually has less voltage drop than a 12V system, meaning brightness will remain stable and consistent across all connected LEDs. In addition, systems greater than 12V support longer strips of LEDs, which lessens the number of required power supply locations.

To put it in context, a 12V system allows about 16 feet of LED strip to be connected before voltage drops impact performance. Depending on the setup and LED type, a 24V system can be extended to 32 feet or more, making it more suitable for architectural lighting, industrial applications, and outdoor installations.

When choosing between these two voltages, consider the scope of your project, the amount of wiring in feet, and the overarching goals of the design. A trade-off between cost, overall value, and uniform brightness will lead to the correct option for your requirements.

How Can You Dim Your LEDs?

Appropriate LED dimming requires you to have the right LED driver and dimmer. Make sure the LED driver supports dimming features. Standard dimming methods include TRIAC (leading-edge), PWM (pulse-width modulation), and 0-10V dimming. Ensure the driver’s dimming method is compatible with the dimmer to eliminate flicker or inconsistency. Also, confirm that the LEDs are dimmable; not all support this feature. Reliable and adjustable lighting control can be achieved with the right driver, dimmer, and LED combination.

Exploring Dimmable LED Driver Options

While choosing a dimmable LED driver, consider the following for better integration and enhanced functioning:

Dimming Technique Used: Choose a dimming technique that suits your application. TRIAC (leading edge), ELV (trailing edge), PWM, and 0-10V are standard options. Each technique caters on a case-by-case basis; TRIC and ELV are common at homes, and PWM and 0-10V are preferred for commercial purposes.

Wattage and Voltage Requirements: Check the ELV driver about your LED lights’ voltage and overall wattage. They should not exceed the data driver, which may lead to system failure. Conversely, insufficient loading can generate instability or flickering.

Cross Compatibility: Check that the driver and dimmer system can interface. Use their specifications to confirm compatibility by checking each against the other’s requirements. The wrong components may cause flickering, reduced dimming range, or complete failure.

Flicker-Free Operating Range: Get a driver that offers expansive dimming without noticeable flicker for cases precise with lighting like studios and medical facilities.

Surroundings and Certification: Consider the surroundings where the installation will go. For outdoor or damp parts, IP65 protective markings should be selected. Additionally, check for marking UL, CE, or FCC to ensure dependability and safety.

Considering all these factors will help you design and implement a fully functional and customizable lighting system that meets all your needs. Talk to reputable suppliers or consult an electrician for further details.

Using Triac and 0-10V Dimmer Systems

Triac dimmers are well-known in homes because they are easy to use and compatible with incandescent bulbs and some LED lights. They reduce the power delivered to the light source by cutting off a percentage of AC voltage, thus achieving smooth dimming. They are inexpensive, easy to set up and perform efficiently in forward-phase or leading-edge dimming systems. However, some compatibility checks must be made with LED drivers to avoid poor performance or flickering.

In comparison, 0-10V dimmers find applications in commercial and industrial areas that require precise control. These dimmers work by varying a command signal (0 to 10 volts) sent to the LED driver, thereby controlling the light output. 0 volts typically corresponds to lights being turned off, while 10 volts corresponds to them being at their brightest. 0-10V systems provide greater flexibility, and their broad applications include architectural lighting, offices, and retail spaces.

Ultimately, you decide whether to use Triac or 0-10V dimmer systems. This decision should be made by paying attention to the specific use case, financial plan, and required control over the system’s functions. Triac dimmers would be preferred for home applications or retrofits with compatible systems. 0-10V dimming systems, on the other hand, would be more appropriate for professional spaces requiring precise, scalable, and modern control over the lighting.

Integrating with Lutron and Leviton Systems

System specifications and interoperability issues are essential when coordinating lighting systems with Lutron and Leviton. Each manufacturer offers a broad selection of dimming methods, including Triac and 0-10V variants for varying uses. Lutron, Caséta, and RadioRA2 systems are best for residential applications as they integrate fully with smart home systems and can be controlled via mobile apps. Lutron’s Quantum systems offer advanced 0-10V dimming for centralized control in commercial installations.

Furthermore, Leviton has Triac systems for decentralized a la carte applications and Decora branded dimmers, which are easily incorporated into other existing systems. Their IllumaTech 0-10V dimmers also offer excellent control for professional environments such as offices or boardrooms.

Always verify your fixtures’ load and voltage constraints relative to the chosen dimmer type to ensure compatibility. Lutron and Leviton’s compatibility documents offer set-up assistance with electronic and component integration. Integrating smart hubs and building administration systems is simple when control protocols and wiring align correctly.

What Challenges Might You Face with High-Power LED Drivers?

Perhaps the most significant issues with high-power LED drivers are the management of heat generated and performance and heated longevity issues relating to how well that heat is dissipated. It can also be complicated to ensure interfaces with dimmer systems and that dimming remains smooth across all performance levels. High voltage also brings problems such as electrical noise, which would interefere with nearby sensitive equipment. These factors make sizing and positioning difficult, as high-power drivers need a lot of space for proper ventilation and installation.

Dealing with Output Power and Watt Requirements

Similarly, while considering output power and watt requirements, I track amplifier and driver power so that the LED arrangement is neither underpowered nor overloaded. Also, to ensure a reliable system, I determine active pulldown power to provide enough buffer for efficiency. Moreover, these devices must operate within their voltage and current ratings for optimal performance and guaranteed safety, meaning LED parameters must be followed. These considerations and factors create a proper balance between steady efficiency and the application’s demands.

Ensuring Compatibility with Constant Current LED Systems

Several critical factors must be optimized for performance and longevity to maintain compatibility with the Constant Current LED systems. Starting with power requirements, Current LEDs are operated at a fixed current ranging from 300mA to 1500mA based on the LED’s specifications. The driver selected needs to be at par with the output current and the voltage range required by the LEDs. For example, if an LED system needs 700mA and 36V forward voltage, a driver tailored to such specifications must be used to prevent thermal overload or flickering.

Another crucial element is Thermal management. During the operation of high-power LEDs, substantial heat is generated, which needs to be removed efficiently, or performance will suffer over time. Heatsinks and active cooling systems containing high heat conducting materials, such as aluminum and copper, would ensure that the junction temperature does not exceed critical levels. As an example, junction temperature in the vicinity of 85°C is often essential for extending the lifespan of the LEDs.

Pulse Width Modulation (PWM) or analog dimming capabilities must also be integrated if a dimming feature is needed. Compromise does not exist when using these methods, as they enhance the quality and efficiency of light emitted. For example, PWM dimming with high-frequency signals above 5kHz improves user experience by eliminating visible flicker.

Lastly, applying surge protection measures with proper wiring setups, such as series configurations for LED arrays, helps mitigate current spikes and power inconsistencies. With appropriate attention to these areas, constant-current LED systems can operate dependably and efficiently with precision standards and user expectations.

Solutions for Low Voltage and DC Power Issues

LED systems that experience problems with low voltage or DC power may result in dim lighting, inefficient system performance, and even damage to the components. Understanding the intricacies of the system’s power supply and methods to control and balance the system is crucial to implementing appropriate corrective measures.

Utilize High-Quality DC Power Supplies: Low-voltage situations can be rectified with constant-voltage drivers or superior-quality DC power supplies. For example, controlled DC supply switching improves consistency and removes supply fluctuations that may drop below operational levels. Furthermore, devices meeting IEC standards, such as those with short-circuit and overload protection, boost supply reliability, stability, and longevity.

Adopt Voltage Boost Converters: Incorporating voltage boost circuits or step-up DC-DC converters dramatically enhances the ability to compensate for low input voltage. For instance, many modern boost converters can raise voltages from as low as 5V to usable levels of 12V or 24V, which allows for adequate LED power without compromising operational efficiency.

Optimize Wiring Layouts: Proper gauge wiring according to the cable length minimizes power loss due to resistance. Low-resistance copper wires and parallel circuit layouts help stabilize voltage levels for systems that cover long distances.

Implementing Capacitor-Based Filtering: Voltage fluctuations can be decreased using capacitors merged with a DC circuit. For instance, transient voltage dips can be eased by discharging and storing energy through electrolytic capacitors close to the LED load.

Real-Time Monitoring System Voltage: One of the newest features includes applying real-time voltage monitoring with smart controllers or IoT devices. These systems alert the users, and therefore, quick steps can be taken to rectify the elimination of the anomaly for optimized operations. Some studies showed that these methods could reduce downtime by 30% with real-time control.

Combining these modern practices with dependable parts helps resolve low-voltage and DC power complications while guaranteeing reliable LED system performance under different conditions.

How to Integrate LED Drivers in a Lighting Project?

Acquiring optimum functionality and lifespan from the integrated LED drivers in a lighting project requires an orderly sequence of activities. First, gather the relevant power specifications of your LEDs, such as voltage and current ratings relative to the driver. Also, confirm what type of system your driver supports, such as constant current or voltage, based on your LED arrangement.

Determine the position of the LED driver to enhance its placement and minimize the wiring and voltage drop. Choose quality components and ensure adequate spacing between parts to prevent electrical interference, overheating, and shorts. Follow the manufacturer’s specifications, instructions, and relevant safety measures during installation. Test the system’s automated functions after installation to verify proper working conditions and general performance.

Planning Your Lighting System with LED Power

Installing an LED lighting system entails carefully calibrating its planning and schematics to ensure efficiency, increased lifecycles, and cost benchmarks. Compared to traditional lighting, modern LEDs offer an outstanding efficiency advantage. For example, when compared to incandescent lighting, LEDs consume 75% less energy, and their lifespan outlasts by up to 25 times, marking them as a preferred option.

As with any layout design, placement should consider the lumen output pertinent to the area. At the same time, ambient residential lighting revolves around 20 lumens per square foot, and kitchens and other task-oriented spaces demand as high as 50 lumens per square foot. When dealing with an LED driver, ensure it meets the combined wattage of the LEDs by accounting for a 10-20% buffer.

Moreover, the specific zone’s preferences in color temperature must also be factored in. Warm white envelopes in a living room or a bedroom (2700-3000K) are best, whereas task-oriented and commercial spaces are better suited with cool white (3500-5000K). Impact-proof, weatherproof LEDs are allowed for outdoor use, regardless of the weather.

Lastly, intelligent lighting controls, like motion sensors and dimmers, should be added to further boost flexibility and energy efficiency. Attention to these factors will guarantee optimized parameters alongside eco-friendliness while retaining full functionality.

Choosing the Right Converter for Your Needs

Choosing the right converter requires careful consideration of your efficiency benchmarks, application type, and input and output parameters. Understanding these elements guarantees peak performance and increased lifespan.

Input and output instructions: First, determine the voltage and current values at the input and output terminals. For example, confirm the required boost or buck voltage range with a DC-DC converter. Modern converters can cover many ranges, such as 12V to 5V or even 24V to 12V, so many systems can use them.

Efficiency Ratings: Converters with high-efficiency ratings repair energy wasted during conversion. This effectively cuts down waste heat released and improves overall system performance. Most converters today include resources with an efficiency rating of greater than 90%, which works best for energy-saving needs.

Power Rating: Check your application’s load requirements. Most converters are rated in Watts (W), and choosing one that covers your maximum power consumption is imperative. For instance, consumer electronics have converters with ratings ranging from 10W to 100W, and industrial applications use higher ratings.

Safety and Regulation Compliance: Pay special attention to the automotive and medical equipment industries, where compliance and dependability are vital. Ensure your converter maintains relevant certifications and adheres to safety standards like UL, CE, or RoHS.

Special Features: Certain converters also offer additional functions, such as overcurrent protection, thermal shutdown, or varying output voltage, that may make protecting devices easier.

Environmental Considerations: When considering the environment, incorporate exposure to vibration and other phenomena like humidity and temperature. Rugged industrial-grade converters help extend the lifespan of the equipment by shielding it from severe environments.

Every project has unique requirements: to ensure success, it is essential to make wise choices specific to the project’s goals. Among the many options available, compact converters for portable equipment and heavy-duty solutions for industrial systems offer increased flexibility when tailoring specifications to application needs, especially in terms of efficiency, reliability, and value.

Ensuring IP67 and UL Compliance in Installations

Compliance with IP67 and UL standards is critical to maintaining electrical and electronic systems’ safety, longevity, and dependability in different settings. The IP67 rating indicates that a device is entirely impervious to dust and can be immersed in water up to one meter for 30 minutes without damage. Such protection is of the utmost importance for outdoor installations, industrial purposes, and areas subjected to extreme weather.

The UL (Underwriters Laboratories) certification concentrates on safety concerning a product’s materials, performance, and construction details. Bearing a UL mark shows that the equipment is safeguarded against fires, triggers auxiliary electrical failures, or even triggers non-dangerous shocks while seamlessly operating during electric load demand tests, and is safe for the immediate surrounding environment. For example, UL-listed enclosures or components are finely scrutinized for electric shock, fire, and mechanical failure.

Innovations in shifts of recent years have permitted incorporating IP67 and UL-certified features into smaller, lighter, and low-power-consuming devices. For instance, combining IP67-rated seals with UL-certified enclosures greatly enhances device protection in remote and heavy-duty settings, making them trustworthy for use in extremely harsh conditions. A study conducted in 2022 showed over 83% of companies that incorporated IP67 and UL-rated parts claimed a reduced environmental failure rate in industrial setups.

To achieve proper compliance, consider installing seals, inspecting the connections, and using manufacturer’s enclosures. These measures can improve compliance from a certified calibrated enclosure. Documentation combined with periodic audits ensures that compliance is being met over time. Following these observations reduces the risk of demanding applications while ensuring safety and longevity.

Reference Sources

The following is a summary of papers and research related to LED drivers 1:

Comprehensive Evaluation System for LED Drivers Concerned with Visual Comfort

Authors: Jieqiong Song, Liqing Tong, Minhua Qian, Yaojie Sun, and Yandan Li

Published by: Fudan University, China

Key Findings 2:

Research has built a detailed assessment framework for LED drivers, concentrating on the relevance of visual comfort.

It demonstrates the effect of driver current, dimming, and driver modes on the LEDs’ Spectrum Power Distribution (SPD), color, and visual comfort.

This evaluation system is based on three elements: system evaluation, driver evaluation, and visual evaluation, which are integrated through the AHP (Analytic Hierarchy Process) method.

The study evaluates the visual comfort impact of driver waveforms and current fluctuations through the dimming process.

A case study of two dimming methods, PWM dimming and SCR dimming, was conducted. The findings indicate that PWM dimming is optimal for studio lighting settings requiring high levels of visual comfort.

Methodology 3:

The study uses AHP, which creates a multi-factor evaluation model.

It incorporates measurable and non-measurable factors like the stability of dimming color and linearity of dimming current concerning time.

An LED driver assessment and comparison are performed using a fuzzy comprehensive evaluation method.

Frequently Asked Questions (FAQs)

Q: What is an LED driver, and why is it important for LED lighting?

A: An LED driver is a self-contained power supply that regulates the power required to drive an LED or a string of LEDs. It is crucial because it ensures that the LEDs receive a constant current to the LED, preventing fluctuations that could damage them.

Q: How do I choose the right LED driver for my LED strip?

A: To choose the right LED driver for your LED strip, consider the total power requirements (wattage), the input voltage available, and the desired output voltage, such as 12vdc or 24vdc. Ensure the driver can deliver the maximum output power required by your LEDs.

Q: What is the difference between constant voltage and constant current LED drivers?

A: Constant-voltage LED drivers provide a fixed output voltage to the LEDs, such as a 12vdc or 24vdc power supply, whereas constant-current LED drivers deliver a constant current to the LED, adjusting the voltage to maintain the specified current output.

Q: Can I use a dimmable power supply with my LED lights?

A: You can use a dimmable power supply with LED lights. Ensure the power supply is compatible with dimming methods like PWM or 1-10v, and check if your LEDs are dimmable. A wall dimmer can be used to adjust brightness levels.

Q: What does Class 2 mean about LED drivers?

A: Class 2 refers to design standards for LED drivers that limit the output power and voltage, ensuring safety and reliability. It often implies that the driver will not pose a risk of electric shock or fire under normal operating conditions.

Q: How does a backpack differ from other LED drivers?

A: A backpack is an LED driver known for its efficiency and ability to provide a constant current to the LED. It is often used in applications requiring a compact and efficient solution for driving LEDs.

Q: What should be considered when using a 60w 12v LED driver?

A: When using a 60w 12v LED driver, ensure the total wattage of your LED setup does not exceed 60 watts. Confirm that the driver provides a fixed output voltage of 12vdc and that the LED lights are compatible with this voltage.

Q: Can I use a 96w 24v dimmable LED driver for high-power applications?

A: Yes, a 96w 24v dimmable LED driver is suitable for high-power applications as long as the total power consumption does not exceed 96 watts. Ensure the LEDs are dimmable and compatible with 24vdc.

Q: How do I calculate the necessary power supply for tape lights?

A: To calculate the necessary power supply for tape lights, determine the total wattage by multiplying the wattage per foot by the total length of the tape lights. Choose a power supply that matches or exceeds this wattage with the appropriate input voltage, like 12vdc or 24vdc.

Q: What is the role of a resistor in an LED circuit?

A: A resistor in an LED circuit limits the current flowing through the LED to prevent it from drawing too much current, which could damage it. It helps deliver a constant current to the LED by maintaining a safe current output level.