Cars can do motion work thanks to the collection of parts that comprise the engine. Commencing from the engine, their working is highly sophisticated. However, the structure looks relatively bright as one understands them calmly and incorporates one step after another. This guide will take you through the essential ‘parts of car engines’ stepwise, so you won’t miss any significant detail while reframing the complexity. Be it a newly licensed driver wishing to learn comprehensively, a passionate auto mechanic, or a curious individual, read on, and we will explain how cars function by illuminating every critical component, starting from spark plugs and ending on pistons. Once we part from this session, we guarantee you will engage more car engines and become more confident in talking or maintaining them.

What Are the Main Engine Parts in a Car?

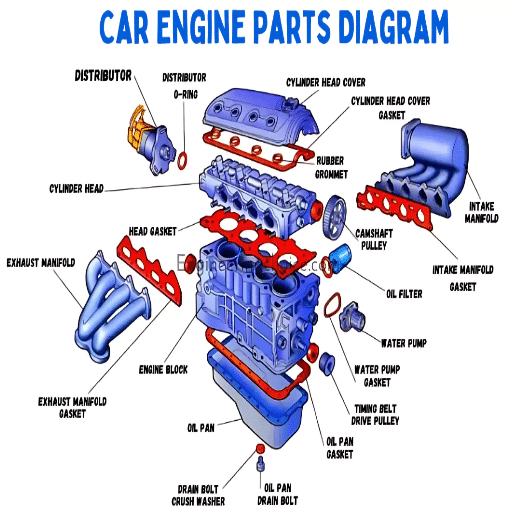

The primary components of an automobile engine are listed as follows:

Cylinder Block: As the engine’s foundation, it contains the key components such as the cylinders, the pistons, and the crankshaft.

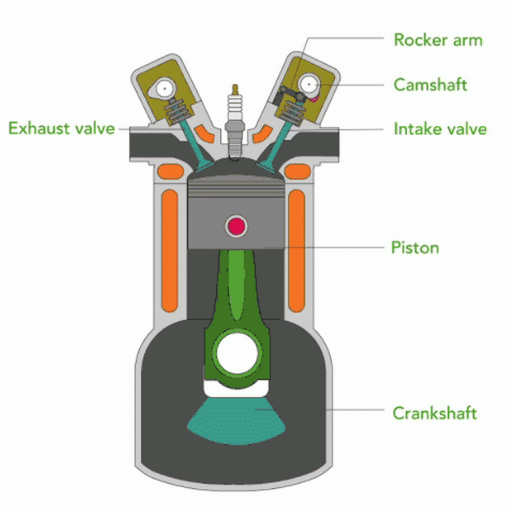

Pistons: To generate power, the vehicle requires a specific type of motion, vertical motion, achieved by the pistons moving up and down within the cylinders.

Crankshaft: The crankshaft is attached to the pistons and is responsible for transforming the vertical motion of the pistons into the rotational motion of the crankshaft, which turns the wheels.

Camshaft: This component also ensures proper fuel and air intake while the camshaft performs exhaust release.

Spark Plugs: These generate power by igniting the combustion air-fuel mixture within the catalysts.

Valves: Intake and exhaust valves control the flow of fuel and air to the cylinders and the exhaust gas.

Timing Belt/Chain: This synchronizes the crankshaft and camshaft, ensuring perfect alignment for efficient functioning.

Fuel Injectors: These mechanisms inject an exact volume of fuel required for combustion.

An effective engine works seamlessly and efficiently in conjunction with every single part of it. Every part listed above works in unison and produces the mechanical energy necessary to power the vehicle.

Exploring the Engine Block and Its Importance

The engine block is often called an internal combustion engine’s heart. Made of cast iron or aluminum alloy, it provides structural support for critical components like the cylinders, pistons, and crankshaft. Modern blocks are contemporaneously made with considerations of strength, heat retention or dissipation, and efficiency, with contemporary practices providing the necessary machining accuracy to ensure quality and reliability.

The engine block’s most significant contribution is structural strength. Physically, the block must restrain the cylinder from moving while simultaneously supporting the combustion pressure and heat. Performance engines often add extra cooling passages or sleeves to the block to improve the engine’s operational temperature. For example, the engines installed in everyday vehicles have an operational temperature range of 195°F to 220°F. With these values, the block must help circulate and remove heat effectively.

Cutting-edge materials science technology has led to the development of lighter engine blocks that maintain their structural integrity. Take aluminum blocks, for example. They significantly decrease the vehicle’s weight, improving fuel efficiency and handling. An automotive survey conducted in 2023 stated that aluminum engine blocks have the potential to reduce a vehicle’s weight by 50 pounds relative to a cast iron block, which could increase fuel economy by about 2-3 percent.

In addition, several engine block design features like bore and stroke measurements directly affect the power produced and the fuel burned. Fuel efficiency and power output are enhanced with the addition of powerful technologies such as turbocharging or direct fuel injection, which advanced block designs can utilize. In summary, the engine block is more than just another component in a vehicle’s engine; it is an intricately designed piece of machinery and, like the rest of the engine components, is essential to the vehicle’s operational dependability and performance.

The Role of the Piston in Internal Combustion

In an internal combustion engine, the piston converts energy from fuel combustion into practical mechanical work. The piston sits inside the cylinder and moves vertically (up and down) in a specific synchronization, owing to the pressure created from each combustion event. Moreover, this upward and downward movement generates a force on the crankshaft through the connecting rod, changing the linear motion into rotational motion with helpful energy.

In today’s automobiles, pistons are made out of light and strong material and relatively enduring to the combustion of heaters, such as aluminum alloys, in extreme temperatures and pressure. For example, during operation, combustion temperature may shoot up beyond 2,500°F, and pressure may go above 1,000 psi. Furthermore, specially engineered coatings with low friction and wear-resistant surfaces enhance performance and durability. Achieving the compression ratio has a significant bearing on the power output, fuel efficiency, and emissions, and it is designed with the required geometric precision in the engine.

Piston capabilities are modified with more advanced options, such as variable compression ratio systems. These systems permit the piston to undergo changing and complex movements concerning the cylinder, making the engine much more powerful and flexible. For instance, the variable compression ratio is set between 8:1 and 14:1, enabling it to enhance fuel consumption in some conditions by 30 percent.

A piston’s role goes beyond only converting combustion energy; it is vital for accomplishing the performance and efficiency of modern internal combustion engines. New advances in design and materials are improving automotive technology’s power, dependability, and eco-friendliness.

Understanding the Functions of the Crankshaft

The crankshaft serves as the centerpiece of an internal combustion engine. It is essential for converting the linear energy of the vehicle’s pistons to rotational energy, which propels the car. The crankshaft rotates in a circular motion to give the drivetrain power while also being meticulously coupled to the pistons via connecting rods. The combustion process then makes the pistons move up and down in the cylinders, rotating the crankshaft.

Modern crankshafts are made of high-strength steel or cast iron to withstand the violent forces of combustion. Reliability and precision depend on the manufacturing process used; therefore, modern factories employ forging and machining. The balance of a crankshaft must be placed in the optimum range to avoid the risk of wasteful and excessive vibration, wear and tear on the mechanical parts, and low efficiency.

The specific designs of crankshafts can also affect an engine’s performance and durability. Lightweight crankshafts optimize responsiveness and support elevated RPMs in high-performance engines. Some crankshafts are designed with added counterweights and harmonic balancers to reduce vibration shocks and enhance the smoothness of the crankshaft rotation when the vehicle is moving at a high speed.

Moreover, contemporary crankshaft design incorporates features to improve fuel economy and emissions. For example, low mass and friction designs help mitigate energy dissipation and enhance the engine’s performance, which is critical for engine functionality. The precision manufacturing processes used to create the crankshaft help achieve lower carbon emissions, which is part of the more significant focus on green automotive engineering.

Industry reports indicate that the specific alloys and manufacturing processes employed in producing crankshaft shafts can improve their operational lifespan by as much as sixty percent over older designs. With further refinement, crankshafts are one of the most essential parts in improving fuel economy, engine performance, and sustainability in internal combustion engines.

How Do Internal Combustion Engines Work?

Mechanical power in internal combustion engines is obtained through air and fuel combustion. The process occurs in the following steps:

Intake: Air and fuel are drawn into the combustion chamber. Compression: The piston compresses the air-fuel mixture to prepare it for ignition. Combustion: A heat source or spark ignites the mixture, forcing the piston downward. Exhaust: The exhaust valve releases the burnt gases from the chamber.

The pistons’ movement continually repeats this cycle, providing the needed rotational power to the vehicle via the crankshaft. Engine performance relies on how efficiently and properly each step is executed, especially in sequence.

The Basics of the Combustion Chamber

The combustion chamber is an integral part of an internal combustion engine that mixes fuel with air so that it can be ignited to produce combustion. Modern internal combustion engines have enhanced combustion chamber designs to achieve better operational performance, fuel economy, and reduced emissions. The chamber’s geometry, dimensions, and the materials used in its fabrication are critical for meeting these objectives. As is the case in many internal components of an engine, combustion chambers are typically made of materials that can withstand elevated temperatures, such as cast iron or aluminum alloys, due to the intense heat and pressure they are subjected to during operation.

Modifications in other areas have also directly impacted combustion performance efficiencies, including the ability to control combustion air-fuel ratios with greater precision, like direct fuel injection and variable geometry turbochargers. For instance, in some modern systems, fuels can be injected at pressures up to 5,000 psi, ensuring adequate mixing in the chamber and improved burning efficiencies. Also, turbocharging compresses the incoming air, raising the oxygen concentration for combustion inside the chamber.

Contemporary designs of combustion chambers pay a great deal of attention to reducing harmful emissions, too. The low-swirl and high-swirl combustion systems are designed to facilitate positive air circulation, which improves fuel combustion, thereby reducing the emission of pollutants. For instance, the advanced engines today can perform with thermal efficiencies greater than 40%, thereby significantly lessening the emission of greenhouse gasses in comparison with older designs.

In addition, developing computers with sophisticated simulation capabilities and improved sensors has allowed engineers to accurately refine combustion dynamics in real-time, functioning under optimized performance regardless of operating conditions. All these innovations illustrate the necessity for the practical evolution of the innovations combustion chambers undergo in their design and functions.

How Spark Plugs Ignite the Air-Fuel Mixture

Spark plugs are essential for starting the combustion process in the engine. They create a high-voltage electric spark that jumps the space between two electrodes. Under the right conditions, this spark ignites the compressed air-fuel mixture in the combustion chamber of the vehicle’s engine, generating energy to power the car.

Modern spark plugs are composed of newer materials, such as iridium and platinum, which are more durable, conduct better, and have higher melting points. Because of this, these spark plugs function well at very high temperatures—often over 2000°F (1100 °C)—inside the engine, which has extreme pressure. The low end of creating a spark is usually around 12,000 volts, and the upper end is 45,000 volts for performance-based vehicles.

This process requires precision with timing; otherwise, it would not be efficient, and this is termed ignition timing. To ensure combustion happens at the right point of the engine cycle, the spark has to be set off at a specific phase to maximize energy and minimize emissions. Modern vehicle management systems can execute timing control with incredible precision using real-life data from sensors, which is advantageous for performance-based vehicles.

Moreover, the development of spark plug technology has enhanced fuel economy and decreased carbon emissions. For example, fine-wire electrode configurations produce more potent, more concentrated sparks, resulting in better ignition of the air-fuel mixture. This improves engine performance and reduces unburnt hydrocarbons and nitrogen oxide emissions in compliance with stricter environmental regulations.

As mentioned, the primary purpose of a spark plug is to convert electrical energy into mechanical power by producing a spark sent to an engine. They enable strategic engine combustion through controlled timings. Meeting the challenge of contemporary engines requires relentless innovation to guarantee dependable ignition, bolster efficiency, and minimize environmental impact.

The Function of the Ignition Coil in Starting the Engine

The ignition coil transforms low-voltage electric energy from the car’s battery into high-voltage current capable of igniting the air-fuel mixture in the engine’s cylinders. It functions as a transformer, increasing the battery’s 12-volt charge to 20,000 to 40,000 volts, creating enough spark to jump across the spark plug.

Advancements in modern ignition coils have made these components more efficient and reliable than their predecessors. These systems include coil-on-plug designs; ignition coils are provided for each cylinder, optimizing spark phasing and minimizing wasted energy. Such improvements improve fuel economy, enhance engine output, and diminish waste products. Moreover, data shows these high-performance coils significantly impact engine efficiency by 5-7%, a critical enhancement in meeting emission regulations and fuel economy standards.

Modern ignition coils are vital for supporting emission regulations and fuel economy standards. They are no longer passive elements but key players enabling the engine to start and run. The reliability of the ignition coil affects the overall vehicle performance; modern automotive engineering, therefore, strives to create reliable and efficient coils.

What are some common engine problems?

Problems within the engine can stem from a range of issues, with the following listed below as some of the more common ones:

Overheating: Left untreated, it can burn up and damage the engine. It is caused by low coolant levels, broken radiators, or even faulty thermostats.

Oil Leaks: Worn gaskets and seals can lead to insufficient engine lubrication, drastically increasing the likelihood of engine wear.

Ignition Issues: Prevent the smooth starting or functioning of the engine due to problems with spark plugs, ignition coils, or the battery itself.

Timing Belt Failure: When a timing belt is damaged or broken, it can completely disrupt the engine’s operation. Some form of severe internal damage usually accompanies this.

Reduced Fuel Efficiency: Dirty air filters, oxygen sensor failures, and clogged fuel injectors may negatively impact performance and fuel economy.

Observing warning signs and performing regular maintenance tends to resolve potential risks, allowing problems to be avoided.

Identifying Signs of a Cracked Engine Block

A split engine block can lead to significant engine destruction, so it is essential to deal with it quickly. The proper repairs will be costly. Here are some general symptoms:

Remember to check if you notice the car overheating. Cars begin to overheat if there isn’t a flow of coolant to cool the engine. A cracked block can cause coolant to leak.

A car leaving suspicious-looking fluid puddles at parking spots is a telltale sign that a coolant crack is burning.

When excessive white or gray fog spews out the exhaust pipes, the fuel is probably seeping into the burning chamber because of a fault.

The defect in the cooling ribs causes an excess of viscous fluids and brain oil, leading to a sudden drop in a car’s towing muscle.

Losing power: Like any vehicle, a car getting older and dependent upon work can lower its health and power of lights. A car’s foundation causes fatigue to its many machines.

Usual Motor Sounds: Soft knocking and tink-tink. Sometimes, make slow cycles of tape in the background, moving slowly around the crankshaft.

Letting too much of them mixing oil with static coolant heavily imprisons moving parts of a discounted car, swollen pistons and camshaft bearings seduced by light slippery oil greasy residue showing around the oil intake cap.

While statistics show that this type of damage accounts for a tiny portion of total engine failures, it remains costly. Maintaining regular upkeep, checking coolant levels, and following engineering policies to prevent overheating and rapid cooling can significantly reduce the odds of this damage occurring.

Dealing with Oil Leaks from the Oil Pan

Leaking oil from the oil pan can damage the engine further. An eroded or broken oil pan is one of the leading causes of oil leaks. Excessive heat and constant pressure can wear out the gasket, leading to time and other complications. Physical damage to the oil pan casing due to road debris and impact is another cause of oil leaking.

To diagnose an oil pan leak, check for any dark or oily stains and patches underneath the vehicle—especially after it has remained stationary for some time. Other symptoms may include continuously dropping oil levels, which may hypothetically activate the low oil level warning on the dashboard.

An oil pan leak repair is usually limited to replacing the defective or broken gasket. Adequate attention to gasket selection, such as those made from silicone or rubber composite combinations, can yield durable and practical seals. While installing the oil pan, always adhere to the vehicle manufacturer’s torque values instructions. Failure to observe these directions will result in excess torque, substantially crushing the gasket and irregularly compressing the pan.

The recommended automotive maintenance policy indicates that everything else is equal, and periodic inspection can decrease the probability of problems associated with the oil pan. Evidence also shows that vehicles routinely maintained, specifically serviced with gaskets and oil pans examined, had fewer oil leaks and ran longer. As a best practice, always check the oil and, when possible, check for leak signs or oil accumulation on the vehicle’s underbelly during regularly scheduled maintenance.

How to Address Compression Issues

When dealing with compression issues, I test the engine’s cylinders to see if they function correctly. If one or more cylinders have low compression, I investigate possible causes, such as worn piston rings, valves, or a blown head gasket. Depending on what I discover, I repair the problem by replacing damaged parts or re-sealing the head gasket. Proactive, regular maintenance helps me avoid more severe compression issues down the line.

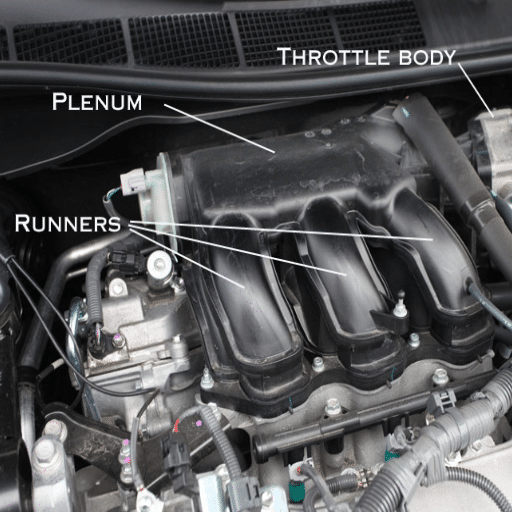

Can You Explain the Intake Manifold and Its Purpose?

The intake manifold subserves as a primary subsystem of an internal combustion engine. It performs the critical task of distributing air, or the air-fuel mixture in some engines, uniformly to all the cylinders to facilitate combustion. That is to say, the intake manifold assists in performance optimization alongside fuel economy. In most cases, it also contains several sensors and valves to control the engine, monitor its emissions, and perform other management tasks. A damaged intake manifold becomes a critical threat to the engine’s proper functioning since any possible problem will lead to insufficient performance.

The Role of Air Filters in Maintaining Engine Performance

Air filters are essential for an engine’s performance and prevent the engine from harmful exhaust pollutants by controlling airborne contaminants. They effectively screen off airborne pollutants, such as dust, pollen, and other particulates, preventing access to the engine to reduce wear on its internal parts. A clean air filter contributes to the optimal air-fuel ratio for combustion while improving fuel efficiency and reducing emissions.

Industry studies show that a dirty or clogged filter can decrease an engine’s fuel economy by 10% and throttle airflow by up to 50%, causing increased strain and reduced efficiency over time. A new filter also enables more excellent acceleration by 11%, demonstrating the contribution of air filters to stable engine performance.

Today’s air filters are made from new materials like synthetic fibers, which improve their durability and filtration efficiency. Regular inspections and periodic replacement of air filters, often due every 12,000 to 15,000 miles, depending on the driving conditions, are necessary to keep any vehicle operating at optimal performance. Ignoring this component can impact the engine’s longevity and increase the need for repairs, a small yet significant investment in the vehicle’s long-term health.

Functionality of the Throttle Body in Air Intake

The throttle body is an essential component of an internal combustion engine since it controls air intake. It lies between the air filter and the intake manifold. The throttle body controls airflow according to the driver’s input via the accelerator pedal. Depressing the throttle opens a throttle plate (or valve) inside the body, allowing more air to flow into the engine. The increased air will combine with fuel, and the mixture will fire to produce the needed power. On the contrary, releasing the throttle plate closes the throttle and restricts airflow, reducing power output.

Electronic throttle control (ETC) is an addition made in modern throttle bodies that removes the mechanical linkages to the throttle plate and substitutes them with sensors and actuators. This change is beneficial because accuracy and responsiveness improve. For example, the throttle position sensor (TPS) measures the throttle’s gate position. Together with the mass airflow sensor (MAF) or manifold absolute pressure sensor (MAP), ETC provides the engine control unit (ECU) with the information needed to control fuel supply and maintain the required air-fuel ratio—usually 14.7:1 (stoichiometric ratio) for gasoline engines.

Inefficient throttle bodies can cause uneven idle, poor fuel economy, and decreased engine power. Regular servicing and cleaning to remove carbon deposits improve airflow and extend the throttle body’s life. Modern throttle body designs incorporate more advanced materials and integrated sensors, which assist in emission control and overall vehicle performance.

How Important Is Engine Maintenance for Longevity?

Car servicing helps maintain the reliability and longevity of the vehicle. Regularly maintaining the engine, such as changing the oil on time, replacing the air filter, and checking spark plugs, minimizes wear and tear, reduces the risk of expensive repairs, and optimizes engine performance. Maintenance ensures the engine components function together efficiently to reduce problems. Ignoring maintenance increases fuel consumption, improves emissions, and shortens the engine’s lifespan. Following the maintenance schedule set by the manufacturer enhances engine longevity and overall vehicle condition.

Regular Check-up of Valves and Gaskets

The proper working order of an engine is reliant on valves and gaskets. Valves control air and fuel intake into the engine cylinders while also permitting exhaust gas to exit. Gaskets, in contrast, seal interfaces between various parts of the engine to avoid leaks while maintaining the optimal pressure inside the engine. If these components wear out, the engine may not function as efficiently as before, which could lead to oil leaks or ultimate engine failure.

Recent statistics suggest that worn or damaged gaskets contribute nearly 20% of engine oil leak issues in older vehicles. Similarly, a valve out of order may combust fuel within the engine and decrease fuel efficiency by as much as 10% over time due to bypassing lean air-fuel mixture. Valves require routine monitoring for carbon deposits, misalignment, and general wear, while gaskets need scans for cracks, warping, or other visible material degradation.

Industry specialists strongly propose incorporating valves and gasket checks with vehicular, stationary periods to optimize maintenance intervals. These components should be checked with other routine parts every 30,000 to 50,000 miles driven, depending on the vehicle’s model and used driving conditions.

Tackling problems that haven’t happened yet “prospectively” saves much money that might be spent on repairs and assures that the engine works at its full potential for a long time.

Importance of Replacing Piston Rings and Timing Belt

Replacing piston rings and the timing belt dramatically impacts an engine’s performance and efficiency. In my professional opinion, a worn piston ring leads to decreased compression, increased oil usage, and, in some instances, damage to the engine’s internals. Just as damaging, a faulty timing belt causes synchronizing movement between multiple engine components and, as a result, will cause catastrophic damage to the engine. Precise timing in replacement ensures proper engine functioning, avoiding repairs while improving the engine’s longevity.

Benefits of Keeping the Fuel Injectors Clean

Injectors must always be clean to ensure an engine runs smoothly and operates efficiently. Fuel injectors guarantee an accurate fuel supply into the combustion chamber, contributing to the required air-fuel mixture. Economic and operational issues stem from dirty or clogged fuel injectors, such as engine misfires, poor acceleration, and elevated emissions. Based on various studies, having clean fuel injectors significantly boosts fuel efficiency by approximately 15%, resulting in significant savings for drivers in the long run.

Maintaining a clean fuel injector contributes to a quieter and smoother operating engine. After some time, deposits that build up can interrupt fuel flow, causing knocking and uneven combustion within the engine. By servicing or cleaning the fuel injectors, appropriate fuel atomization is achieved, resulting in improved responsiveness alongside power output while reducing fuel waste. Furthermore, clean fuel injectors help to decrease carbon deposits that accumulate in other engine components, which assists in maintaining overall engine health and prolonging its lifespan.

For modern vehicles with advanced fuel injection systems compliant with emission regulations, cleanliness is crucial for fuel injectors. Having cleaner fuel injectors can reduce harmful emissions, aiding in eco-friendly efforts while keeping the vehicle within legal bounds. With periodic cleaning and proper maintenance, injectors can operate optimally, increasing the vehicle’s lifespan and improving the driving experience.

Reference Sources

The following is a summary of the main findings and methods of the papers related to engine components:

-

Application of Titanium and Its Alloys for Automobile Parts1:

Key Findings: This study underscores the advantages of titanium in engine components because of its strength and lightweight. The reduction of weight in an engine’s parts increases fuel economy as well as performance.

Methodology: The study aims to examine the different material properties in the automotive industry, paying attention to the technological benefits of titanium alloys.

-

Modeling and Simulation of Torsional Vibration in Engine Crankshaft Systems2:

Key Findings: This research focuses on studying the dynamical behavior of rubber components used in engine crankshaft systems, with special attention to rubber damper pulleys. The analysis shows the effects of these parts on torsional vibration and engine performance generally.

Methodology: The techniques used to study rubber parts under dynamic conditions are numerical simulation and modeling.

-

Machine Parts Recognition and Defect Detection in Automated Assembly Systems3:

Key Findings: This research proposes a computer vision defect recognition system to recognize and detect various types of faults in mechanical parts, especially automotive engine parts. Another emphasis is on defect recognition, which improves production efficiency and minimizes cost.

Methodology: The method applies two-dimensional computer vision methods comprising image processing, contouring, shape normalization, and part-outlined image preprocessing. Defect recognition is performed based on correlation methods using the parts’ outline or silhouette with the set contour of the part.

Frequently Asked Questions (FAQs)

Q: What are the main parts of a car engine?

A: The main parts of a car engine include the cylinder head, camshaft, crankshaft, oil pump, flywheel, timing chain, sump, and intake valve. These essential car engine parts work together to ensure the engine runs smoothly.

Q: What is the function of the camshaft in a car’s engine?

A: The camshaft is responsible for opening and closing the intake and exhaust valves in the engine, allowing air and fuel into the combustion chamber and letting exhaust gases out. It plays a crucial role in the engine’s overall performance.

Q: How does the oil pump function in the parts of a car engine?

A: The oil pump circulates oil under pressure to the engine’s rotating bearings, sliding pistons, and camshaft. This helps to lubricate the engine components, reduce friction, and cool the engine, preventing damage and ensuring efficiency.

Q: What role does the clutch play in a car’s engine?

A: The clutch connects and disconnects the engine from the transmission system. It allows the driver to change gears and control the power transmitted from the engine to the wheels, enabling smooth acceleration and deceleration.

Q: What are the symptoms of a failing lifter in the engine?

A: Symptoms of a failing lifter include engine tapping or ticking sounds, a reduction in engine performance, and smoke coming from the exhaust. If left unchecked, it can lead to further engine damage.

Q: What could cause smoke coming from the exhaust?

A: Smoke from the exhaust can be caused by several issues, such as burning oil, coolant leaks, or incomplete combustion within the engine. Identifying the smoke’s color can help diagnose the problem: blue indicates oil, white suggests coolant and black points to excess fuel.

Q: What are the essential parts of the car engine that require regular maintenance?

A: Basic parts of the car engine that require regular maintenance include the oil pump, timing chain, intake valve, cylinder head, and camshaft. Regular checks and maintenance help prevent engine wear and extend the engine’s lifespan.

Q: How do pushrods function in parts of a car engine?

A: Pushrods are used in overhead valve engines to transfer the cam’s rotary motion to the rocker arms, which open and close the valves. They are an integral part of the engine’s valve train system.

Q: What is the impact of the rotation of the crankshaft on engine performance?

A: The crankshaft’s rotation converts the pistons’ linear motion into rotary motion, which drives the vehicle’s wheels. This is crucial for engine operation, directly affecting power output and efficiency.

Q: Why is it important to know your engine type?

A: Knowing your engine type is vital for understanding your car’s engine’s specific parts, maintenance needs, and capabilities. This knowledge helps troubleshoot issues, perform upgrades, and ensure optimal performance.