Ball valves are widely used across numerous industries and are appreciated for their dependability and adaptability. Whether controlling liquid movement within technological pipelines or maintaining efficiency in a home plumbing system, it is essential to manage the different types of ball valves alongside their applications. This post aims to serve as an ultimate guide to help you make informed decisions by explaining the different designs and materials that constitute the functionalities of ball valves. Understanding their specialized features and practical benefits will provide valuable insights on performance optimization while traversing various settings. Read until the end to uncover all you need concerning these indispensable devices that control fluid flow.

What is a Ball Valve and How Does it Work?

A ball valve controls the flow of liquids or gases using a hollow spherical element, sliced through the middle, and mounted on a rotating shaft. The valve is open, and the medium can pass freely when the ball’s hole is in the same direction as the flow. Movement of the handle or actuator to the pivoted ball shall turn it by 90°, and the flow will be blocked; thus, the valve is closed. In addition, ball valves are the fastest and most reliable stream closure devices in industrial processes. They are rugged, easy to work with, and are thermally and mechanically resistant, which is why they dominate in the equipment of factories and homes.

How does a ball valve regulate flow?

A ball valve controls flow using a spherical ball with a hole (bore) at its center. Fluid passes through the ball valve entirely unrestricted as long as the lined-up hole is in the plane of the pipeline. The ball flow is fully stopped when the solid portion of the ball is rotated to 90° with the handle or actuator. Modern ball valves are manufactured with sophisticated and exact engineering to guarantee minimal pressure drop during fully open positions, enhancing fluid or gas flow efficiency.

Based on the latest engineering specifications, ball valves can handle pressure up to 1,000 psi, depending on material and design specifications. Their range of operational temperatures from -200°F to over 500°F makes them versatile for many applications. Technological progress in ball valves, such as PTFE and reinforced elastomers as advanced sealing materials, has adapted to serve in corrosive and high-pressure environments. Moreover, high operational efficiency is achieved by applying quarter-turn actuators and automated control systems, especially in industrial processes where operations from a distance and precise flow control are required.

What are the main parts of a ball valve?

A ball valve’s primary sections include:

Body—An assembly’s outer casing protects the valve’s components, ensures its structural integrity, and allows interconnection to the piping system.

Ball—A media controlling spherical part of the assembly, which has a cylindrical bore along its axis. Opening and closing the valve is accomplished by rotating the ball component.

Stem—The shaft connecting the ball to an external lever or actuator, thus permitting manual (through lever) or automated operation.

Seats—Components usually consist of rings made of soft or hard materials like PTFE. They provide additional soft or hard material to form a strong bond between the ball and body and control leakage.

Seals and Gaskets—These components ensure inter-component connections without gaps between the valve parts.

Actuator or Handle—The external part of the assembly used for manual (lever or handle) and powered rotation (powered actuator) of the ball.

These components ensure the ball valve performs its intended function in various settings by promoting innovative engineering for durability, efficiency, and reliability in flow control.

Why are ball valves commonly used in industries?

The fluid ball valves are preferred in industries to control liquid flow due to their effectiveness, operational control, and overall reliability for managing fluid flow. Their general level of durability makes handling high pressure and extreme temperatures drawn out. Considerable examples are that they can work at 10,000 psi and -200°F to 500°F, depending on the material used.

In addition, ball valves are simple, requiring minimal servicing and repairs in a practical way, which aids the economic benefits of using them for an extended period. This is because of the simple, fewer movable parts design, which lessens the strain that they will go through, thus ensuring long operational life. The oil and gas, chemical processing, water treatment, and HVAC industries heavily use ball valves because of their fast shut-off response time, minimal torque demand, and maintained functions. With continuous report predictions, the ball valve market is growing at an outstanding rate, reaching around USD 12 billion in 2022, mainly for optimized flow control solutions across various industries.

Another thing that makes them popular is their different uses and preferred configurations. Floating ball, trunnion-mounted, and multi-port faucet designs are a few examples of configurable ball valves.

Their adaptability to different forms of materials, such as liquids, gases, and even slurries, enhances their suitability for varying industrial applications.

Exploring Different Types of Ball Valves

Floating Ball Valves: Floating ball valves are a type of valve in which the ball is not rigidly fixed; instead, it is positioned via the compression of two elastomeric seats. Such valves are frequently utilized in low—to medium-pressure systems since they function on upstream pressure to seat the ball into the downstream seat, which provides an effective seal. Their simplistic design enhances the floating ball valve’s cost efficiency and suitability for small pipeline systems.

Trunnion-Mounted Ball Valves: A trunnion-mounted ball valve has a ball fixed in place by a trunnion, thereby receiving additional support. This type of construction is beneficial for high-pressure applications because it lowers the operating torque needed to turn the ball. They are standard in oil and gas and other industries where high strength and dependability under harsh conditions are essential.

Multi-Port Ball Valves: As their name suggests, multi-port ball valves have three or more ports, which increases versatility in regulating flow and provides flexibility. Because they can control flow paths, they are mainly used for fluid movement and mixing systems. These valves provide a much-needed answer for complex piping systems by lessening the number of installed valves and other components in the multi-port systems.

Knowledge of the differences among these varieties helps choose the correct type of ball valve for a specific industrial need. Every design is meant to address specific operational challenges and offers particular advantages.

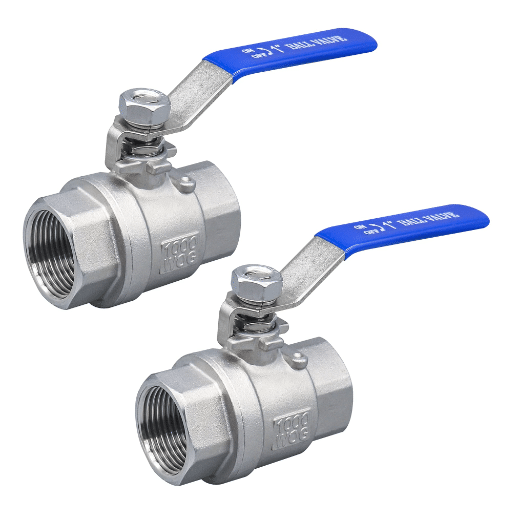

What are two-piece ball valves?

Due to their practical design, two-piece ball valves are among the most widely utilized across different sectors. Each valve’s two parts possess an element of the valve structure: a body and a connection end. Such a configuration greatly simplifies periodic maintenance since the valve can be removed without disconnecting the entire assembly from the pipeline.

Such functionality is handy for processes where contamination is not allowed, since both pieces are airtight and do not allow fluids to seep. Two-piece ball valves are usually made of corrosion-resistant, durable materials like stainless steel and brass, significantly improving their longevity in harsh working conditions.

Two-piece ball valves are standard in water, oil, gas, and chemical applications. They tend to have high temperature and pressure ratings; many are designed to exceed 1,000 psi and operate at temperatures between -20°F and 400°F (-29°C and 204°C), depending on the materials used. These attributes make two-piece ball valves one of the most popular and economical options for industrial, commercial, and even residential systems that require reliable, high-performance, and low-maintenance.

How does a three-piece ball valve differ?

Three-piece ball valves are different from two-piece designs mainly because of their versatility and ease of maintenance.

Unlike the two-piece valve, which has two parts that hold the ball, the three-piece ball valve consists of three separate sections: two end caps and one middle body. This modular structure makes partial disassembly possible without disconnecting the valve from the piping, which is hugely advantageous.

The three-piece configuration certainly enhances durability and improves resistance to wear in high-pressure or high-cycle environments. Depending on the material construction (stainless steel, carbon steel), these valves can withstand pressure ratings up to 1000 psi or more. Their operational temperature range is also extensive, usually from -20°F to 400°F (-29°C to 204°C), which makes them reliable in demanding applications.

The operational advantages further enhance flexibility due to the use of interchangeable parts. Users may replace specific components or upgrade materials to match different media or operating conditions, reducing long-term expenses and downtime. Such versatility is one of the reasons why three-piece ball valves are widely used across disparate industries, including oil and gas, chemical processing, and wastewater treatment.

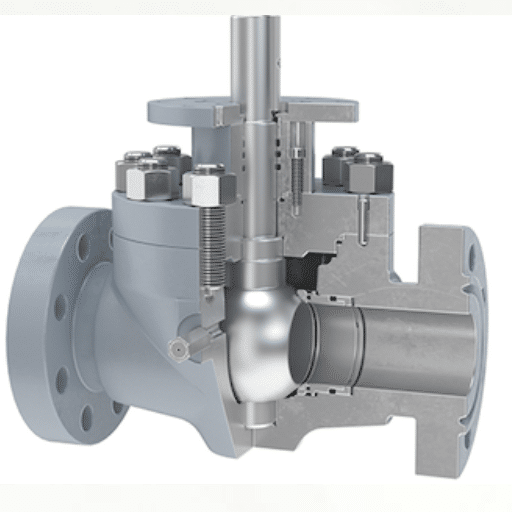

Understanding the trunnion ball valve mechanism

High-pressure trunnion ball valves can appropriately address high-pressure applications. Unlike floating ball valves, these have a shaft, referred to as a trunnion, that supports and holds the ball in place. This design feature minimizes excess movement within the valve, improving the seal and reducing torque requirements. The reduced operational torque makes the valves fully effective in automated systems or when manually operated.

The seats are spring-loaded in ball valves to maintain a firm grip on the ball. This spring-loaded mechanism is very effective in low—and high-pressure environments (e.g., upstream pressure compresses the seat against the ball, thus enhancing the tightness). This unique dual-pressure sealing system yields more efficiency while ensuring reliability in critical industries.

Trunnion ball valves are primarily used in pipelines with diameters more than 4 inches, where they can withstand a pressure rating of 20,000 psi. Constructed using stainless steel, carbon steel, and alloy, they display remarkable strength and endure damaging corrosive substances. Modern constructions often incorporate cavity pressure relief systems, lessening dangers associated with the thermal expansion of media trapped within the valve.

These valves are used extensively in the oil and gas, petrochemical, and power generation industries that require safe and accurate fluid flow control. They also enhance safety with features like double block and bleed isolation, which allows users to relieve pressure on both sides of the valve during maintenance. The versatility of the trunnion ball valve’s design and its operational characteristics accounts for its widespread acceptance in the control of complex fluid systems.

How to Choose the Right Type of Ball Valve for Your Needs

Please pay attention to the following criteria for selection of the right class of a ball valve:

Applicative Considerations: Establish the valve’s intended use with the type of media (liquid, gas, or slurry) it is designed to regulate. Some valves, such as trunnion ball valves, are more appropriate for high-pressure systems or large-scale operations.

Material Compatibility: Confirm that the valve’s components do not react with the intended media in a way that would cause corrosion or damage. Some examples are stainless steel, carbon steel, and brass.

Pressure and Temperature Ratings: Confirm that the valve will operate within the temperature and pressure limits while maintaining safety and efficiency.

Control Preferences: For the required level of automation and control, decide on manual, electric, or pneumatic operation.

Maintenance and Safety: If safety and maintenance protocols are primary concerns, fire-safe or double block and bleed valves are preferred.

Complying with the criteria above allows for the selection of a ball valve, which guarantees effectiveness and consistency in performance in a fluid control system.

What factors affect ball valve design choices?

Each application has specific requirements and conditions that dictate various considerations for ball valve design choices.

Material selection: Selecting valve materials directly impacts maintenance and interaction with the materials. Stainless steel, brass, and PVC are some of the common materials. Stainless steel is best for corrosive applications, while low-pressure environments can utilize PVC due to its lightweight and low cost.

Pressure and temperature ratings: Operating conditions require a proper limit on pressure and temperature. Extreme rotary ball valves can exceed 10,000 psi and operate from -50°F to over 800°F, depending on the designed components and materials used.

Type of media: The nature of the media, be it gas, liquid, or slurry, influences fluid design. Abrasive or highly viscous substances could require specialized coatings that reinforce seats to reduce wear.

End connection type: End connections, whether threaded, flanged, or welded, define the seamless interaction with the piping system. Flanged connections are widely adopted in industries due to their dependable seal and ease of maintenance.

Flow Characteristics: When constructing ball valves, considerations like full-port versus reduced-port must be made depending on flow requirements. Reduced-port valves are more cost-effective, while full-port valves are unrestricted, resulting in minimal pressure drop.

Actuation Method: Trends seem to lean toward fully automated systems using electric actuators for precision, which interface with the valve manually, electrically, or pneumatically.

Regulatory Compliance: Most industries require API, ASME, or ISO compliance, and some are more strict, like the food and pharmaceutical industries, which require valves to meet rigorous sanitary requirements.

Environmental and Safety Considerations: Focusing on precision and minimal impact has led to modern ball valve designs integrating operational safety with features like fire-safe ratings and low-emission sealing.

Selecting appropriate ball valves tailored to system needs can meet compliance and precision requirements, efficiency expectations, reliability, and regulatory compliance.

Comparing full-bore ball valves and reduced-bore ball valves

Every system has unique requirements, which means full-bore and reduced-bore ball valves differ in design, use, and features:

Flow Capacity: Full-bore ball valves have a bore diameter that matches the pipeline, ensuring no flow restrictions and minimal pressure drop. Reduced-bore ball valves entail a smaller bore, leading to increased pressure drop, although this suffices in many general industrial applications.

Applications: Full-bore valves are ideal for operations where efficiency is critical, such as pigging systems or pipelines transporting sensitive media. Systems with cost-effective pressure drops and cost efficiency tend to use reduced bore valves.

Cost and Material Savings: Reduced bore valves weigh less and are more cost-effective, requiring less construction material. On the other hand, full-bore valves are pricier but perform better in areas demanding reliable flow rates and energy efficiency.

Pipe Stress and Erosion: Full-bore valves have a smooth flow profile, which helps reduce pipe stress and erosion. In reduced-bore valves, the low-friction design helps mitigate flow turbulence and potential stagnation, although, in low-velocity systems, lack of friction does not create significant problems.

The right valve type ensures system performance while remaining cost-efficient and meeting the desired efficiency standards. Understanding the differences allows these standards to be readily available.

When to use a floating ball valve?

The simplistic structure and flow regulation prowess of floating ball valves make them easy to use in various sectors. These valves are well-suited for applications needing high-stakes sealing, such as underwater or pressurized environments. Floating ball valves are standard in systems with low to medium operational pressure and a nominal pressure of 40 bar, or 580 psi, such as those transporting water, gas, or oil.

One of the defining attributes of floating ball valves is the provision of a bubble-tight seal. Their floating mechanism allows the ball to be pushed against the downstream seat by the pressure from the medium, thus ensuring dependable sealing even if misaligned to some degree. They provide robust sealing with minimal activation, which makes these valves effective for fierce shut-off applications.

Floating ball valves are cost-effective and compact, making them ideal for systems under less pressure and in compact pipelines. Their low price and lightweight add to their benefits when used in systems with low pressure and smaller diameters compared to other trunnion-mount valves.

However, it is essential to remember that floating ball valves are inappropriate for applications involving very high temperatures or greater diameters where uneven pressure or excessive torque could influence sustained performance. While selecting a floating ball valve, it is essential to observe the temperature and pressure of operation, as well as the nature of the medium, to guarantee proper functioning and durable service.

Understanding Ball Valve Design and Features

The ball mechanism serves as a closure for ball valves, as it can rotate within the valve’s body to regulate the flow of the medium. These valves are selected primarily due to their long service life, simple operation, effectiveness, and strong sealing. The main parts of a ball valve consist of the body, a sphere (the ball) with a stem and an actuator or lever for manual or automated control, its seats, and seals.

Ball valves are best known for low operating costs and maintenance, quickly stopping flow, and no detectable fluid leakage. They come in two primary styles: floating ball valves and Trunnion-mounted ball valves. Floating ball valves use the pressure of the medium to achieve sealing. At the same time, Trunnion-mounted versions are better for high-pressure or larger bore applications because of their stabilizing support mechanisms.

While ball valves are versatile, they are equally complex, considering size, pressure rating, material compatibility, and the environment in which they will be operated. This versatility makes them adaptable to various uses, particularly desirable to the oil and gas industry, chemical processing, and water treatment systems.

What are the key features of a ball valve?

Robust design elements enable reliable, leak-proof sealing in ball valves. Their quick shut-off functionality provides ease with a quick 90-degree turn of the handle. Ball valves are remarkably durable and compatible with many materials, providing diverse usage. They withstand high pressure and temperature while maintaining adaptability and versatility in size and type. Additionally, requiring low maintenance with a long-lasting service life makes these valves industrially applicable.

How does the hole in the ball affect flow control?

The hole in the ball is pivotal for controlling flow volumetrically and temporally. Turning the handle allows positioning the ball’s hole with the pipeline, aligning both, allowing max flow because the aperture matches the pipe diameter. Conversely, rotating the ball so the hole aligns perpendicular to the flow results in complete blockage, preventing fluid or gas passage. This control provides precise on/off control with minimal resistance when fully open, referred to as a “full port” design.

For example, research and industry norms indicate that full-bore ball valves have a negligible pressure drop. This allows for smooth, non-turbulent flow, especially in systems where energy efficiency is critical. On the other hand, reduced bore (or “standard port”) ball valves are narrower than the pipeline, with a lighter flow. These utilize a higher pressure drop, but are still prevalent in systems that can tolerate these limitations. Their high efficiency and accuracy in controlling flow make ball valves indispensable in water treatment, oil and gas, chemical processing, and manufacturing systems.

Exploring multi-port ball valves and their applications

Multi-port ball valves integrate several components to simplify fluid control within a single valve body. Unlike traditional two-way ball valves that possess only an inlet and an outlet, multi-port ball valves have either T-port or L-port geometries, which exploit diverse media flow patterns: divert, mix, or isolate. In addition, multi-port ball valves reduce additional system piping complexity and the need for multiple valves, saving space in the overall layout and installation costs.

Because of their versatility and efficiency, multi-port ball valves are utilized widely for other industries such as chemical processing, food and beverage, HVAC, or industrial manufacturing. For instance, T-port valves can effectively split a flow into multiple containers or equipment, while L-port valves can isolate flow in some portions of the pipeline. Such valves are made of durable materials like stainless steel, brass, or PVC, which can withstand harsh conditions that these components often endure.

According to new statistics, the global market for ball valves is anticipated to experience considerable growth, particularly in the adoption trends of multi-port ball valves alongside an increase in operability. Industry reports further suggest that multi-port valves have an increasing utility in improving overall operation cycles, thereby optimizing maintenance downtime. Modern fluid control systems use these valves because of their importance in handling multiple pressures, diverse temperatures, and other sophisticated conditions.

In addition, automation technologies have extended the functionality range of multi-port ball valves. These valves can now be controlled remotely by installing actuators, thus providing accuracy during automated processes in sectors such as water treatment and energy production. Innovations like this boost user convenience and the reliability of these multi-port ball valve systems, establishing them as a fundamental component of industrial systems.

Applications and Limitations of Trunnion Ball Valves

Due to their strong construction and better sealing mechanisms, trunnion ball valves are frequently used in the oil and gas and power generation industries where overbearing temperatures and pressures require dependable flow control and shut-off. These valves support trunnion-mounted stems and work well for large-diameter pipelines.

Besides their advantages, trunnion ball valves do face some problems. Due to their complicated design, they are usually pricier than floating ball valves. Also, their large size works against them when they need to be installed in small spaces. Despite these disadvantages, they are still popular in harsh working industrial conditions due to their unrivaled dependability and efficiency.

Where are trunnion ball valves used?

Trunnion ball valves are widely used across various industries, as they offer substantial operational dependability and performance under work stress conditions. Because of their design and durability, these valves are advantageous for use in large-diameter pipelines and high-pressure systems. Critical segments of the economy, such as oil and gas, petrochemicals, power generation, and chemical processing, depend heavily on trunnion ball valves to perform key functions.

In particular, the oil and gas industry relies on these valves for upstream, midstream, and downstream operations like conduits, offshore platforms, and refinery systems. These valves are selected for these systems because they ensure a tight seal, regardless of pressure and temperature fluctuations. Industry figures report that the oil and gas industry has the largest trunnion ball valves market share, as the growing energy demand supports further market growth.

Power plants also use these valves for precise control in cooling systems and steam pipelines, where control of liquid flow and durability of the valve are critical. Because of their durability in extreme operational conditions, these valves are your best choice for protecting safety and assuring the operational efficiency of equipment.

Their scope of use includes water treatment facilities, LNG terminals, and mining operations, showing industry-wide applicability. These valves are engineered to meet rigorous safety and reliability benchmarks, thus underscoring their importance as an integral part of contemporary industrial systems.

What are the benefits of a trunnion ball system?

The trunnion ball system provides countless advantages, making it resourceful in many industrial applications. Outstanding performance in high-pressure situations is paramount, and its benefits are paramount. Unlike floating ball designs, the trunnion ball system is affixed to an axle, eliminating the excessive torque needed to open and close the valve even in extreme pressure situations. This design smoothens operational performance and decreases wear, improving the valve life.

The ability to guarantee a reliable, tighter seal with minimal leakage gives the trunnion ball systems an edge. The use of spring-loaded seats guarantees better sealing due to low-pressure applications. These properties are necessary in the oil and gas industries, where leakage is a safety hazard that can compromise the environment.

Furthermore, these systems are built to withstand harsh environmental conditions and aggressive fluids and are made of materials that lack corrosion. This aligns with the goal of trunnion ball systems to meet international safety standards such as API 6D and ISO 14313, verifying their quality irrespective of continuous application.

Research suggests that the decreased operating torque also translates to energy savings using actuators, specifically a 20-30% energy reduction compared to floating ball systems. Furthermore, the maintenance expenditures are much lower due to the well-built systems that reduce wear and tear over time. All these advantages lead to improved operational efficiency and lowered total cost of ownership, which is why the trunnion ball systems are favored in industrial applications.

Limitations of using trunnion ball valves in specific scenarios

Considerations for Specific Situations: Although the use of trunnion ball valves provides benefits with operation efficiency and versatility, some drawbacks must be taken into account for certain situations:

Installation Difficulty and Costs: Trunnion-mounted ball valves have an increased floating ball valve installed cost due to the trunnion-mounted inertia. This includes the additional work needed to install the valve, which may consist of specialized skills or equipment for proper installation. Floating ball valves, for example, have a much more convenient installation. As such, floating ball valves are far more convenient and streamlined for specific industries with a strict budget.

Valve Weight and Size: Due to the added design features and robust construction, trunnion-mounted ball valves possess more weight and robust dimensions than bottom-floating ball valves. This makes them unsuitable for weight-sensitive offshore platforms and systems that prefer trim designs for placement. However, they can be mounted on offshore rigs and platforms that prefer compact constructions.

Lower Pressure Performance: Trunnion ball valves cannot optimize low-pressure systems, as they favor high-pressure operations. Their intricate sealing systems and additional design features make them overengineered for low-pressure applications that require simple designs. The ample seals and complex construction also create a situation where extra spending occurs without equal returns.

Challenges of Maintenance in Certain Environments: Although the robust design of the trunnion ball valves does reduce maintenance work due to the operation’s frequency, some environments with high salinity and generally corrosive substances remain troublesome.

Increased Operational Costs: These environments impose added expenses because additional precautions must be taken to ensure their operation, such as adding corrosion-resistant materials. This problem intensifies operational costs.

Rounding Up: Understanding their respective limitations is critical to ensuring smooth performance for industrial operations using these maintenance-appropriate devices. The balance of cost and performance hinges greatly on proper evaluation against specific application conditions.

Reference Sources

Optimized Design for High-Precision Ball Valves

Performance Analysis of a Ball Valve for Gas Pipelines

Experimental and Numerical Study on Pressure Drop Coefficient of Ball Valves

Frequently Asked Questions (FAQs)

Q: What is a ball valve, and how does it function?

A: A ball valve is a type of valve that uses a pivoting ball to control the flow of liquid or gas. When the valve is closed, the ball blocks the flow, and when it is open, the port ball aligns with the flow path, allowing materials to pass through.

Q: What are the different types of ball valves available?

A: Ball valves come in various types, including one-piece, full-bore, and high-pressure ball valves. Each type is designed for specific applications and offers different features.

Q: What are the main applications of ball valves?

A: Ball valves are commonly used in oil and gas, water treatment, and chemical processing industries. They are valued for their durability, ease of operation, and ability to provide a tight seal.

Q: How does a full-bore ball valve differ from a standard one?

A: A full-bore ball valve has a larger port ball that matches the pipeline’s diameter, reducing pressure drop across the valve. This design is ideal for applications where minimal flow restriction is critical.

Q: What is the significance of the ball and seats within a ball valve?

A: The ball and seats are crucial components used in ball valves. They ensure a tight seal when the valve is closed, preventing leaks and ensuring efficient flow control.

Q: Can ball valves be used as a control valve?

A: Although primarily used for shut-off, specific ball valve designs can function as control valves by precisely adjusting flow rates. However, they are less effective than specialized control valves like globe valves.

Q: What distinguishes a quarter-turn valve from other types?

A: A quarter-turn valve, such as a ball valve, requires only a 90-degree turn from fully open to fully closed. This quick operation makes it advantageous for applications requiring frequent and rapid operation.

Q: Are ball valves suitable for high-pressure applications?

A: Yes, high-pressure ball valves are designed to withstand significant pressure, making them suitable for demanding applications in various industries.

Q: What is the advantage of using a vented ball in certain valves?

A: A vented ball allows trapped pressure within the valve to be safely released when the valve is closed, preventing potential damage or leakage.