A functioning turn signal switch is essential for ensuring road safety and your car’s functionality. Whether replacing a broken switch or installing a more efficient one, selecting the right one for your vehicle’s make is essential. In this article, we evaluate some of the best turn signal switches available. We delve into their features, suitability, and build quality. By the end of this article, you will know the turn signal switch that works best for your vehicle, so safety and efficiency are guaranteed every time you drive.

What is a Turn Signal Switch and Why is it Important?

Understanding the Function of a Turn Signal Switch

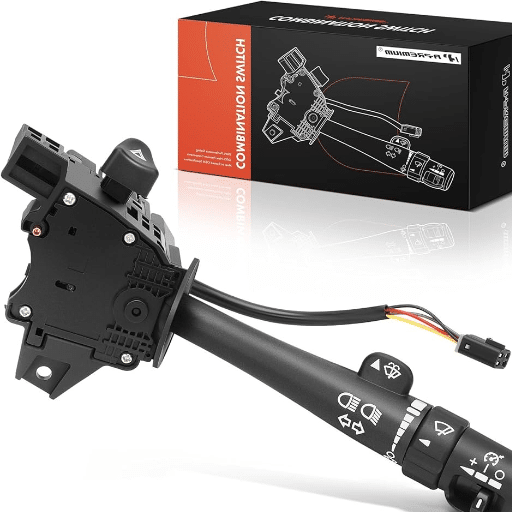

Designed for controlling the movement of your vehicle, the turn signal switch allows you to signal movements intended by the driver. This device is usually placed on the steering column, allowing the driver to access it to turn on the signals easily. These indicators help communicate the intent to turn left or right, or simply change lanes on a road. Modern switches also perform other duties apart from signaling turns; these include controlling the headlight, windshield wiper, and cruise control.

Traffic safety organizations believe that the improper or neglected use of turn signals is a cause of many accidents. This means a turn signal switch cannot be overlooked. This device puts your mind at ease, dealing with the possibility of your vehicle having unmatched signals. A reliable turn signal switch enhances safety on the roads by reducing vehicle miscommunication.

Symptoms That Indicate the Turn Signal Switch Is Faulty

A faulty turn signal switch can exhibit some poor symptoms that can be dangerous while driving and compromise the safety features of your vehicle. An indication that most people notice is intermittent or non-working turn signals. Failing to activate the turn signals or having them blink randomly could signal a problem with the internal workings of the switch. This malfunction could create problems for other drivers who rely on signals to predict your next move. Also, participants in road traffic could easily identify that your vehicle is not canceling the turn signal after turning, which is a clear sign of mechanical failure. This malfunction indicates the turn signal switch is faulty and needs repair.

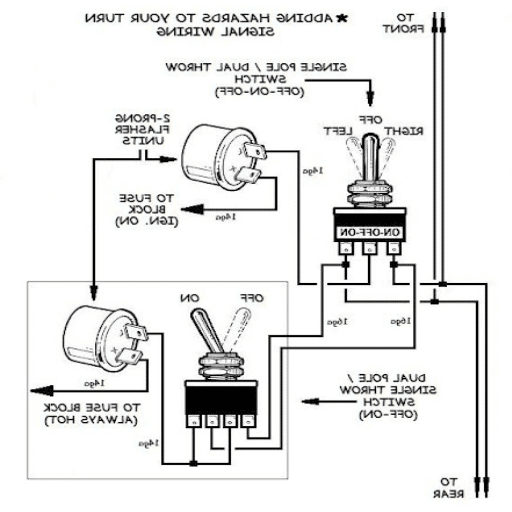

Another vital sign to notice is when the hazard lights are malfunctioning or no longer working. Turn signal and hazard light issues often share a single control switch in most vehicles, thus an issue in one is likely to be a system-wide problem. Additionally, turn signal switches can cause electrical problems, such as blown fuses and faulty relays. Drivers may also observe unusual clicking noises, burnt smells, or even dim or dead dashboard indicators when the system is turned on, all of which should be concerning.

If these warnings are ignored, greater complications may arise while driving, including an increased risk of accidents or faulty signaling to other vehicles. Performed routinely, a turn signal switch inspection alongside its switch can ensure safety on the road, help meet legal requirements for avoiding speeding violations of traffic laws, and, best of all, prevent regulatory scrutiny of vehicle retention tools that turn cap wheels. Taking action towards the problem early will bolster trustworthy signaling while traveling and deter expensive repair work in the future.

The Importance of the Turn Signal Switch in a Vehicle

Turn signal switches are vital parts for maintaining safety while driving. Road safety relies on all motorists having an understanding of how traffic is controlled via signals. Signal use boosts communication between drivers and reduces collision rates, for example, during lane changes or turns.

In addition to increased safety, research shows that using signals properly increases the chances of accidents resulting from signals not functioning correctly. Turn signals are designed to withstand stress; however, once they become too worn out, they stop functioning altogether.

Failure of turn signals can lead to poor signaling, making coordination difficult for both pedestrians and motorists. Promoting roadway communication by turning off and on signals when necessary helps keep drivers and everyone on the road safe from collisions in coordinated traffic scenarios.

What Are the Best Replacement Turn Signal Switches Available?

Best Heavy-Duty Turn Signal Switches

When selecting a heavy-duty turn signal switch, its durability and suitability with other parts are essential considerations. One of the best recommended products is the Standard Motor Products DS-1439 Turn Signal Switch, which is praised for its solid build and easy functionality. This switch is suitable for many vehicles, making it useful for personal and commercial use, as it is designed to handle frequent use and harsh driving conditions. Furthermore, its ease of use makes it a dependable choice for long-term use.

The ACDelco D6253C Turn Signal Switch is another excellent option, built with the care and quality that ACDelco parts are known for. This switch is highly recommended for its exceptional electrical conductivity and wear resistance. It simplifies the installation process, making it popular among both professionals and DIY installers. In addition, this model is known for undergoing extensive aftermarket testing throughout its life, which helps prevent reliability issues, making it dependable for safety-critical operations.

Finally, the APA/URO Parts Turn Signal Switch is designed for use with heavy-duty vehicles, providing improved protection against environmental factors such as dust, moisture, and temperature changes. It includes reinforced internal components that lower the likelihood of failures, even in highly demanding environments. Prioritizing dependability and operational lifespan, this switch is a worthy purchase for drivers who regularly operate in rough off-road terrain or extreme climates. These features not only maximize performance but also enhance vehicle safety during operation.

Most Popular GM Vehicle Turn Signal Switches

While looking for parts to use as turn signal switch replacements for GM vehicles, some choices stand out due to their effectiveness, reputation, and versatility. One of the most popular options is the AC Delco D6254C Turn Signal Switch, as it comes with OEM standards and is designed specifically for GM vehicles, like all AC Delco products. It integrates easily with the vehicle’s lighting system, thus reducing installation problems. Aside from its ease of integration, this switch is also notable for its strong construction, made of quality materials designed to withstand more than a fair share of use and exposure to the elements. Furthermore, the switch’s controls over signal light, hazard light, and other related functions enhance its adaptability and reliability.

Another outstanding option is the Standard Motor Products CBS-1311 Turn Signal Switch. The switch will work with all vehicle makes and models and operates at an exceptional price. Fitment of the signal, wipers, and, in some cases, cruise control (depending on the model) is done without any issues. Like the rest of CBS-1311’s products, durability and ease of installation have helped this product earn acclaim. Customers report smooth operational control over time.

For all GM drivers looking for an advanced option, replacement turn signal assemblies from brands like Dorman have worked well. Installation is convenient due to effortless application, and modern molding and circuitry have been added for optimal functioning. Many of these types also feature other safety additions to the vehicle, such as automatic cancellation of turn indicators, which greatly improve the ease of use while driving. No matter which replacement switch is selected, it is crucial to focus on the make of the replacement windows, as quality will maintain safety standards and efficient signaling functions.

What to Consider When Selecting A Part for a Turn Signal

It is essential to pay close attention to specific features when selecting a turn signal replacement part for a GM vehicle to ensure reliability and efficiency. Initially, it is necessary to consider the year, make, and model of the car. This is because a properly designed switch will help safeguard against fitting issues that could result in electrical malfunctions. In addition, top-notch materials are essential, as high-durable parts will resist damage over time, thereby prolonging the component’s life.

Other features to look for include automatic cancellation functions that offer more advanced capabilities and convenience. In addition, more modern replacement parts come equipped with energy-efficient circuitry designed to conserve power. Choose parts that have undergone rigorous testing and meet safety standards to ensure dependable performance in various conditions. Lastly, ease of installation is now offered in many modern options, saving considerable effort and time. These factors help in selecting parts that enhance a vehicle’s safety and performance level, while also providing a reliable turn signal replacement.

How to Diagnose and Fix a Bad Turn Signal Switch?

Most Common Reasons a Turn Signal Switch May Break

A turn signal switch can stop functioning properly for several reasons, most of which are related to damage, electrical issues, or simple wear and tear. For starters, one of the most common reasons refers to wear and tear. Since the turn signal switch is an active part of driving, it is rotated many times during a trip. As a result, many small parts, such as springs and contacts, are used, and these parts can fail, leading to damage or even rendering switches unusable. Moreover, external damage due to external factors, such as a force applied to the steering column or improper assembly, can cause damage to the switch itself.

Aside from this, an electric system problem can create another concern. Signals produced by the switch, connections containing broken wires, and a frayed wire present in the steering column can sever the electrical connection between the switch and the lights, resulting in malfunctioning lights and signals. Besides, a malfunctioning fuse in the car’s fuse box can stop the signal from functioning as needed. Additionally, corrosive substances may slowly wear away at the solder points, allowing the switch to operate. This is worse in hot, humid areas where moisture-containing electrical contacts are present, as slow ingress can lead to problems.

In addition, the buildup of dirt and debris in the switch assembly can interfere with its movement or affect the flow of electricity. Failing to fix this problem may result in signals that are stuck or intermittent. Addressing an issue with a turn signal switch that is assumed to be faulty requires troubleshooting, which often involves checking for physical damage to the switch and testing the circuitry for continuity using a multimeter. Drivers are empowered to effectively troubleshoot and resolve signaling system problems by understanding these factors, which helps them restore their vehicles while ensuring safety on the roads.

Detailed Instructions for Replacing a Turn Signal Switch

Check for the Tools Required: Collect the following tools: a multimeter, flathead and Phillips screwdrivers, flashlight, and the vehicle’s service manual. These tools should allow for safe vehicle testing.

Remove the Battery: Skip step one of disconnecting the battery to pull the car’s electrical system. This protects the switch from damage while turning the signal switch during the test.

Get Access to the Turn Signal Switch: Remove the steering column trim or cover to access the turn signal switch assembly. Depending on your vehicle model, this may require unscrewing panels or unclipping some fasteners. Check your vehicle’s service manual for precise instructions to prevent unnecessary damage.

Inspect for visible damage: Conduct a visual inspection of the turn signal switch along with the wiring harness attached to it. Check for damage in the form of corrosion, stray voltage, broken wires, burned areas, or other signs that may indicate an issue. Resolve any issues before proceeding with the tests.

Test the switch with a multimeter: Set the multimeter to the resistance or continuity range. For every position of the turn signal switch, verify that the multimeter probes are connected to the proper switch terminals as specified in your service manual. A multimeter connected to the output terminals must register the readings that confirm the switch has been activated. Without continuity on a closed circuit, it indicates a faulty switch.

Check the Wiring: If the switch works, follow the wiring traced to it and look for any problems. Look over the connectors for loose or corroded pins. Check continuity through the harness. Use the multimeter to measure continuity between the probes in suspected problem areas. Correct any wired or connected joints that fail these tests.

Check the Flasher Relay: It can also be a flasher relay in a turn signal lamp. Check the relay to see that it is working to specification. Relays are generally interchangeable; for testing, a like-functioning relay can be used in the fuse compartment, or relays can be checked individually with a multimeter.

Reassemble and Retest: Get the steering column back in, reconnect the battery, and with everything inspected, tested, and corrected, the only thing left is test the left and right signal indicators and check the conditions intended.

With these methods, you can resolve issues within your turn signal switch while keeping the vehicle signaling system precise and safe for travel.

When it’s Time to Change Your Turn Signal Switch

Your signal switch needs replacement when specific problems arise, which can pose risks to its safety and functionality. Common signs include the signal failing to turn on, getting stuck in position, or blinking erratically. Further complications include a lack of responsiveness with the lights and difficulty turning off the signal after turning the vehicle off, all of which indicate a failing switch. These challenges can come from worn-out electrical contacts, internal mechanisms, or simply corrosion over time.

It’s advised to check the turn signal switch if these problems persist. If these systems are faulty, the chances of an accident due to unclear communication with other drivers increase significantly. Driving with faulty systems can cause any system to malfunction. The average life expectancy of a signal switch is several years with regular use, especially with higher-use vehicles. Early signs of failing indicators shouldn’t be dismissed, because the damaged switches contribute to the issue and ensure compliance with road safety regulations.

What is a Multi-Function Switch and How Does it Work?

Multi-Function Switch vs. Standard Turn Signal Switch

In a vehicle’s electrical and control systems, a multi-function switch and a standard turn signal switch have different areas of operability. As the name suggests, a standard turn signal switch does only one job, which is to control the functioning of a car’s turn signals. This helps communicate the drivers’ intentions for safety while enhancing compliance with lane and road regulations. The design and operation of this type of switch are simple, as it controls the left and right turn signals.

In contrast, a multi-function switch integrates multiple elements into one part, making vehicle control more efficient. Besides operating the turn signals, the multifunction switch usually has other features, such as controlling the windshield wipers, high beams, hazard lights, and even cruise control in some cases, all of which are located on or near the steering column. This is easier for the driver since all essential components are integrated into one reliable unit.

From a technological perspective, multi-function switches are usually more complex and robust because of the several circuits and functions that operate at the same time. Complexity is also noted in their construction as they include extra wiring, contacts, and control elements. The simpler design of standard turn signal switches may mean less repairs needed, but due to the expanded functionality multi-function switches tend to be more prone to repairs required due to increased load in wear and tear, auxiliary features in constant-used vehicles or those with frequent use auxiliary features tend to add multiple functions utilize increase wear and tear usage. The replacement cost for multi-function switches tends to be higher, but at a reduced price.

The differences between the two forms of switches need to be emphasized for maintenance, on-board diagnostics, and car upgrades. Multi-purpose switches incorporate almost every other control one has to use in the car. In contrast, the standard turn signal switch meets the needs of simple control requirements and works perfectly in minimalist control design scenarios.

How to Determine If a New Multi-Function Switch is Necessary

Understanding the need for a multi-function switch replacement relies on identifying some signs of damage or malfunction. Inconsistent operation of the components, such as vehicle turn signals, windshield wipers, headlights, and others, is one of the most common problems. For instance, if your turn signal actively fails to function or is stuck in a constant flash mode, this could indicate a faulty switch. Equally, erratic windshield wipers or the failure of headlight controls to switch on may indicate that the multi-function switch is defective.

Physical malfunction is another concern, particularly within older cars. A decrease in the operational precision of mechanical or electronic devices, also known as wear and tear, is quite common when an object is used repeatedly. Parts of plastic switches can become “spongy” and do not provide enough resistance. After-car electrical problems can include blown fuses, as well as the more esoteric computer-generated issue of strange clicking or buzzing sounds emanating from the steering column, which may indicate a defective switch that needs to be replaced.

Multi-function switch failures do not escape vehicles with more advanced electronics; error codes linked to these failures may appear. Such alerts should be heeded as they significantly reduce the chances of complications down the line. These actions must be taken to not only prevent complicated violations of essential vehicle systems but also to improve overall driving safety and comfort.

Multi-Function Switch Installation Tips

Installing new multi-function auto switches begins with proper planning and safety considerations. Start by removing the vehicle’s battery to avoid any sparks. The multi-function switch is usually located inside the steering column; hence, you need to remove any trims or panels adjacent to it.

First, remove the old switch using the proper tool, paying attention to the wiring connections. Be careful when removing the wiring harness, as you don’t want to break any connectors. If this new switch has changes in design or features, follow the manual for installation steps and any additional wiring changes.

Put all of the trim pieces back on the new switch and screw everything down tight. After reattaching the battery, perform a functionality test of the multi-function switches and all their components, including turn signal functionality, wipers, and headlight alignment and elevation. By taking these measures, you will maintain the safety features of the automatic multi-function switch. If help is needed, don’t hesitate to call an auto electrician.

How to Install a Turn Signal Switch in Your Vehicle?

Tools Needed for Installing Turn Signal Switch

Before I started installing the turn signal switch in my car, I made sure I had all the necessary tools, which included a steering wheel puller, flathead screwdrivers, Phillips screwdrivers, and a socket wrench set. These tools acted as wheels for the vehicle, in the sense that each was capable of performing a different task, such as taking apart the steering wheel or loosening bolts. These effectively enhanced my installation and didn’t compromise the value of conducting a clean and efficient one.

While working, I greatly appreciated a good flashlight to see inside enclosed spaces. Additionally, matching the flashlight’s capability were my high-end pliers for taking apart clip and wire combinations, which aided in removing these sections. I also suggest acquiring trim removal tools built for detaching plastic coverings with gentle edges, as I did. Adhering to all these processes, I was able to control loose wires with electrical tape and connectors. Given my arrangement, I executed this task with greater efficiency as I faced little to no issues and frustration.

Procedure for Replacing the Turn Signal Switch

The first thing I did when trying to replace a turn signal switch was to disconnect the car’s battery. This was important because there could have been an unintentional short circuit during the work. The next step involves removing the steering column cover. I grabbed a screwdriver and meticulously removed each screw and placed it in a container, so I don’t lose any. The cover is now off, so I can reach and see the turn signal switch.

The next step was to remove the wiring harness connected to the defective turn signal switch. Because of the fragile nature of the wires, I made sure to ease off the clip without pulling too much while releasing the connector. After that, I unscrewed the old switches from the steering column and carefully slid them out. The new switch was simple to install; all I had to do was put it into the correct position and then secure it into place by fastening the screws. I also made sure that the wiring harness was connected securely. Lastly, I checked that all connections were tight before fitting the steering column cover back into position.

Afterward, I attached the car battery and checked to see if my installation of the new turn signal switch was working. Working through all the light functions showed that everything had been installed correctly. Many steps require focus and time, but the effort put in beforehand greatly simplified the process and was satisfying in the end.

Mistakes to Avoid When Fitting New Equipment

It is highly recommended that the car’s battery be disconnected for maintenance work before any installation. Forgetting to turn off the battery power whilst carrying out maintenance on the electrical parts of the vehicle can result in short circuits, parts burning, and, in some cases, injuries. Safety measures, such as turning off the battery and removing the turn signal switch, can help eliminate potential issues.

One of the more glaring oversights is forgetting to capture the wiring connection during the dismemberment phase, noting each step along the way. An attempt to reconnect wires without a reference will likely result in the wrong wiring being used, which could lead to defective signaling and other issues. Operational and functional chaos can be avoided easily by taking notes or snapping pictures of the setup.

Driving a vehicle is widely accepted as a norm in modern society, and doing so while putting the driver’s safety at risk is not acceptable. Poorly secured and misaligned components deceivably make it look as though there is no problem with the installation. A close check on the alignment, along with a double check on the connections, ensures that the installation is both seamless and durable. Close attention to such details enhances efficiency and makes the installation process smoother.

-

TruckSpring: Replacement Turn Signal Switches for Heavy Duty Trucks – Offers OEM replacement switches for various truck models.

-

The Jalopy Journal: High Quality Turn Signal Switch? – A forum discussing high-quality turn signal switch options.

-

RZR Forums: Turn Signal Kit Options – A discussion on different turn signal kit setups.

-

For A Bodies Only Mopar Forum: Best source for turn signal switch – Insights into sourcing and repairing turn signal switches.

-

Reddit – Mechanic Advice: What turn signal switch should I go for? – Community advice on selecting the right turn signal switch.

Frequently Asked Questions (FAQs)

Q: What is a turn signal switch, and how does it work?

A turn signal switch is a part located on the steering column multifunction switch, allowing the driver to control the turn signal lights. While the driver pushes the turn signal lever, it energizes the flasher module, which causes the turn signals to flash in the intended direction of the turn the vehicle is making.

Q: What are the common symptoms of a faulty turn signal switch?

A: These symptoms may appear as not flashing, expecting blinkers to activate but the lights don’t activate, or the turn signal lights illuminating remain non-flashing and quickly turn off without a repeating period. In certain situations, the signal arm can be quite slack or not in its initial position, where the user has toggled it.

Q: How do I find the correct turn signal switch part number for my car model?

A: If you check the manufacturer’s website, auto parts stores, or even the car workshop, they might offer you the needed information by looking at your vehicle manual, as well as enabling you to obtain the proper turn signal switch number. Supplying them with the manufacturer details, the car’s model, and the year it was produced helps in issuing the right component.

Q: Is it possible to fit a universal turn signal switch on all types of vehicles?

A: Usually, a universal turn signal switch can be fitted on different vehicles, but the wiring and installation must be done properly. You should also check if it fits your vehicle’s electrical system and if you know how to properly set up the wiring harness.

Q: Which part does the turn signal flasher belong in the signaling system?

A: Their responsibility includes controlling the operation of turn signals. They are responsible for the proper timing of the turn signals and the rate at which they flash, ensuring that other drivers can see the indicator lights. The failure of the flasher could cause the turn signals to work improperly.

Q: What steps do I take to diagnose an issue with my turn signal system when the lights do not respond?

A: The first step to diagnose the issue is to check if the bulbs have blown out. After that, check the fuses that are part of the turn signal system. If those are fine, check the lines and connections to the turn signal switch and flasher module for any faults or loose connections.

Q: If only the vehicle’s turn signals are not working, do you have to change the entire combination switch?

A: Not in all situations. The problem could be due to the turn signal flasher or some wiring issues. On the other hand, if the combination switch is relatively old or some of its functions are already failing, it would be cheaper in the long run to replace the entire unit.

Q: Do you think that turn signal switches are different for classic cars and more recent vehicles?

A: They do. Turn signal switches for classic cars may differ in design and wiring from newer vehicles. Older cars are likely to have mechanical switches, while more modern ones have electrical switches controlled by a body control module (BCM) that can control several functions, including turn signals.

Q: What do I do if my turn signals are flashing faster than usual or do not flash at all?

A: Significantly faster flashing signals may suggest that a fuse or bulb has burnt out, while no flashing at all indicates that the turn signals are entirely dead. Perform the basic electrical troubleshooting on the turn signal switch, wiring, and fuses to isolate the problem.