Employing linear rail systems in industries is improving productivity and precision in operations. Automation equipment, robotics, medical apparatus, and advanced technologies use these components. This makes it clear that they are high-tech, and smooth motion is essential for unmatched precision and reliability. This article will discuss the workings of linear rail systems, their applications, and the impacts they wield on contemporary industries. Advanced and curious engineers will gain insight into linear rails’ role in modern engineering and what drives technology today. Click here to read more!

What are the key advantages of linear rail systems in industrial machinery?

The contributions of linear rails to precision and accuracy in manufacturing processes

Carrying out processes and steps in a sequence is composed of several linear intervals referred to in manufacturing as movements to accomplish a task or set of objectives. These steps are conducted smoothly with the least vibrations possible to avoid breakdowns. Linear rail systems linear guide with rail systems are modular components, ensuring high precision and accuracy are accomplished in a factory setting.

The functions of a manufacturing plant, such as electronics, aerospace, and medical devices, require standards where tolerances are in the magnitude of microns, which is one millionth of a meter. Misalignment during smooth motions such as linear steps leads to vibration while expanding and decreasing shape, which deteriorates performance over time. These advanced functions require precise and advanced machinery, which demands electric components, hardened steel frames, and ceramic surfaces to withstand repetitive strain and rest cycles while still retaining performance.

Linear rails work seamlessly in unison with CNC machines and robotics, sparking the possibility of synchronized automated tasks working in parallel, further boosting accuracy with heightened production speeds. In conclusion, adopting linear rails into manufacturing systems provides an instruction set for the robot, increasing accuracy with stunning levels of quality to remain competitive in today’s industry.

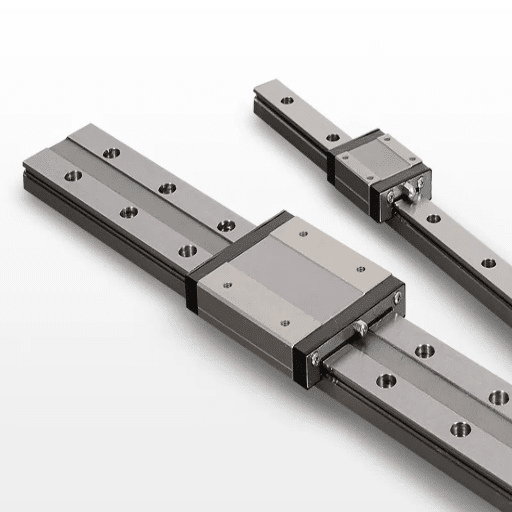

Benefits Of Load Capacity Regarding Linear Guide Rails In Industrial Applications

Guide rails have a critical function in the automotive, aerospace, and even large-scale machinery manufacturing industries as they can withstand extremely high loads. In such cases, linear guide rails provide automotive manufacturing, aerospace, and large-scale machinery production services. Guide rails for linear motion systems can withstand high forces and evenly distribute them throughout the system. This reduces individual component stress and guarantees critical damage-free use, enhancing durability and decreasing wear and tear.

A classic example is heavy-duty linear guide rails that carry several tons of equipment and aid in precision and multi-ton equipment movement, such as those built from high-carbon steel or coated alloys. Also, bearings used as rolling elements lower the friction greatly, easing movement even under extreme loads. This contributes vastly to unsurpassed stresses and ensures reliability in highly repetitive tasks.

Additionally, highly stressed applications at mobile and thrust components are increasing with linear motion systems where innovation, such as dual line tracks and optimizing ball bearing arrangements in the rail design, have led to better load distribution and an increase in guidance stability. These increase the operational and static stability of basic units critical to heavy machinery. This lets us efficiently work with linear guide rails custom-designed for specific load-lifting tasks.

Considerations regarding linear rail longevity and service life for long-term operations

The degree of material care, rail design accuracy, and maintenance practices influence the service life of linear rails. If the primary factors determining operating conditions are considered, precision manufacturing and smooth surface static contact can be accomplished using computer numerically controlled or high-quality machining processes. Using alloy steels with advanced heat treatments poses minimal corrosion, wear, and fatigue failure during long-term operations.

Regularly applied lubricants are essential for optimal performance of linear guide systems. Proper adjustment is vital to enhancing the lifespan of components with moving parts by increasing protection against wear and contamination. In addition, dust and debris prevalent in industrial environments require the application of cover shields to prevent particulate ingress and consequently maintain constant operational efficiency over prolonged periods.

Load alignment and capacity affect long-term durability. Not overloading linear guides and evenly distributing loads helps avoid over-exerting the guide system’s components. Failure to properly align parts can cause imbalanced wear and catastrophic breakdowns, making part alignment checks necessary. Moreover, applying modern maintenance techniques like wear and monitoring sensors provides the ability to deal with issues before they arise. It ensures that operations continue without having to halt machines and equipment for repairs.

These added factors require the use of advanced materials, precise fabrication, and cross-section analysis, which further enable the creation of linear rail systems tailored for heavy-duty industrial usage.

How do linear rails improve manufacturing efficiency compared to traditional systems?

The Impact of Linear Motion Guides on Production Speed and Throughput

Linear motion guides are a marked development in contemporary manufacturing technologies, significantly increasing production speed and overall throughput. Unlike typical mechanical systems, linear rail guides are designed for precision and smooth motion, minimizing the friction encountered during movement. This optimization enables faster and more accurate machinery positioning, subsequently improving production cycles. These advancements greatly benefit industries with high-volume output, such as automotive assembly or semiconductor manufacturing, as the improvements save critical time with minimal error margins and ensure that established production quotas are consistently and efficiently met.

Reduced maintenance requirements also play a significant role in improving throughput. Traditional systems frequently face issues related to wear and tear because of the high friction levels, leading to recurrent repairs and downtime. The advanced design and materials used in linear rail systems translate to lower friction coefficients and exceptional durability. This results in increased maintenance intervals without losing reliable performance over an extended period of operation. The combination of reduced downtime with the ability to sustain high loads and repetitive motion enables sustained operational periods of the production lines, further increasing output capacity.

Furthermore, incorporating linear motion guides into automation technologies gives manufacturers an unmatched advantage in flexibility and scalability. Linear guides can be integrated with robotic arms, CNC, 3D printers, and other automated equipment, allowing unprecedented workflow systems surpassing traditional setups. Not only does this save time, but it also allows for enhanced customization in manufacturing processes. From low-volume production for prototypes to full-blown mass manufacturing, manufacturers can respond to market demands due to the unprecedented precision and speed offered by linear guides, all while ensuring quality standards are maintained.

Minimizing maintenance downtime with premium linear rail guides

Premium linear rail guides are specifically designed to the highest construction standards to reduce the linear wear and tear experienced over an operational lifetime, significantly decreasing maintenance costs. These components are tailored to function under enormous, demanding loads and conditions using carefully selected materials and precise manufacturing techniques. Maintenance downtime can be minimized through self-lubricated and sealed lubrication systems. These enhanced features work towards maintaining reliable function, free from contamination that often leads to failure in lesser-quality guides in place of better-maintained friction.

Moreover, modern models of linear guideways often have corrosion resistance and higher stiffness values, which are essential for harsh industrial applications. For instance, stainless steel rails or those with anti-corrosive plating suffer less damage because of moisture and industrial chemicals. This strengthens durability and lowers maintenance burdens, allowing firms to reallocate resources toward enhancing productivity.

In addition, premium quality linear guides have high accuracy, which mitigates alignment errors and controllable wear, which limits unplanned maintenance activities. Using premium-grade linear rail assemblies enables companies to reduce operational downtime by almost 30 percent. This decrease illustrates the economic advantages of improving operational efficiency. Undoubtedly, these advances in engineering make the linear rail guides a crucial component in reducing reliability and availability disruptions in manufacturing systems today.

Improvement of energy efficacy by components of linear motion systems

Optimizing linear motion components has become practical as energy efficiency becomes more critical across multiple industries. The engineering of these parts is complex in that it minimizes friction and energy waste to allow motion systems to function at their best. For example, modern linear rail guides are constructed with low-friction cloths and sophisticated ball bearing systems, which allow for better movement. Energy is not the only thing conserved; the wear and tear on the parts is minimal, resulting in increased sustainability by reducing waste.

Furthermore, new energy-saving designs and materials have emerged. Heavy inertia exerts a great deal of energy for lifting, which is readily alleviated by using alloys of light and high strength in the manufacture of linear products. Also, many designs now incorporate automated lubrication systems that use energy to overcome wear resistance. Collectively, these changes help companies improve productivity while reducing energy expenditure, resulting in savings operationally and environmentally.

The effects of these optimizations are palpable, as businesses report reductions in energy consumption. As a case in point, some research indicates that assembly lines outfitted with advanced linear motion systems can lower their energy use by as much as 20%. This reduction in energy consumption directly decreases expenses and minimizes environmental impact. Energy-efficient technologies are becoming more critical than ever in light of international efforts to promote sustainable manufacturing, showcasing the importance of linear motion devices in the more inclusive context of responsible and streamlined industrial activity.

Which industries benefit most from linear rail implementation?

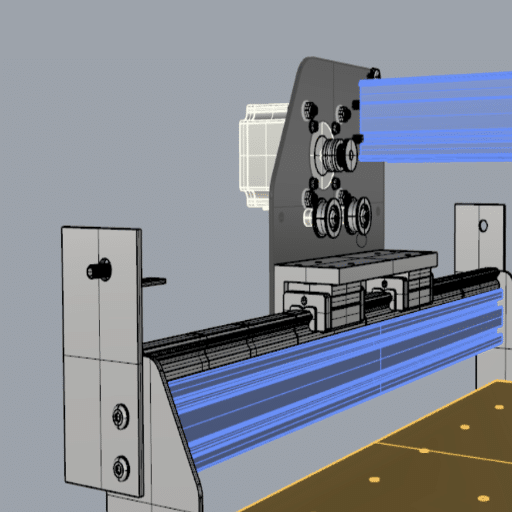

Precision and Applications of Linear Guides in CNC Machines

Linear guide systems are critical components in CNC machine applications that require utmost accuracy. These systems provide smooth, accurate, and repeatable motion necessary during operations like milling, turning, and laser cutting. For instance, incorporating linear rails in CNC machines allows these machines to attain accuracy in terms of positioning within microns, which is important for aerospace, automotive, and medical device manufacturing sectors.

Also, the design innovations and advanced materials used in the fabrication of guides have enhanced the performance of linear guides even further. Modern industrial systems use self-lubricating corrosion-resistant surfaces, increasing the guides’ longevity and lowering maintenance needs. Furthermore, linear rails can bear high loads and efficiently withstand stress while enduring high-speed machining processes.

From the data perspective, industries that use CNC machines are experiencing a jump in production efficiency from 15%-20%. This increase in production efficiency leads to higher throughput and lower operational costs for the CNC machine users. In addition, linear guides’ ability to retain accuracy while undergoing prolonged operations ensures consistent quality; therefore, linear guide systems are a must-have in high-precision manufacturing environments.

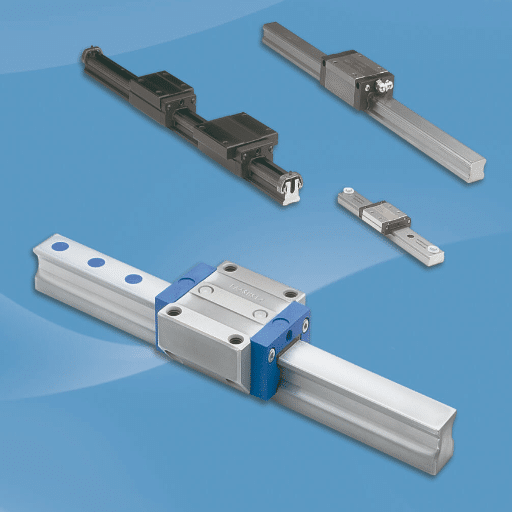

Enhancing the Performance of 3D Printers With Miniature Linear Rails

The 3D industry has made leaps in precision, speed, and reliability due to the invention of miniature linear rails. As modern guiding devices, these linear rails make movement along the vertical, horizontal, and depth axes (X, Y, and Z) much smoother and more accurate. Miniature linear guides outperform rods and belts because they minimize vibration, eliminate backlash, and vastly improve print quality. With these components, modern 3D printers can now consistently achieve ultra-fine layer production and intricate detail on prints.

Miniature linear guides also help achieve even higher printing speeds without compromising quality. Traditional Means often have problems when trying to balance speed and accuracy. However, with low friction and increased movement control provided by linear rails, printers can push to higher rates while still preserving tight tolerances. In fact, some models of 3D printers have been benchmarked to achieve a whopping 25% boost to speed alongside comparable accuracy to positioning with high-quality miniature linear rail systems.

The benefits of miniaturized linear rails concerning 3D printing precision systems incorporate durability and longevity. Miniaturized linear rails of stainless steel and other materials subject to wear-resistant treatments are designed to ensure prolonged operational cycles. The miniature linear rails possess durable characteristics that lower maintenance needs and provide dependable productivity throughout the machine’s entire life cycle. Such features serve various industries, from prototyping to end-use part machining, where operational uptime served with precision matters the most. By adding miniature linear rails to hobby-grade 3D printers, enthusiasts and manufacturers can achieve the promise of quicker, more precise, and better high-quality results.

Use of linear motion guides in heavy-load industrial applications

Adding linear motion guides is critical for the performance and accuracy needed in heavy-load industrial applications. These guides are designed to reach a specific level of weight capacity for smooth, accurate movement at various degrees of motion and within rough environments. The functions enabled by these guides for automotive production, aerospace, and heavy machinery industries include but are not limited to simple and complex motions in material handling, robotic systems, and entire assembly lines.

The CNC linear guides are designed to withstand harsh environments with state-of-the-art features. It can handle rigid workloads due to its superior resistance to wear, high rigidity, and reinforced load capacities. In CNC machining, guides enable high precision and repeatability while processing dense and abrasive materials. Moreover, advanced automation like automated lubrication and new coating technologies result in longer guides’ lifespans, thus increasing productivity and operational efficiency. With the integration of high-performance linear motion guides, industries can significantly optimize productivity and gain unmatched operational efficiency, even under demanding workloads.

What factors should be considered when selecting linear rails for industrial use?

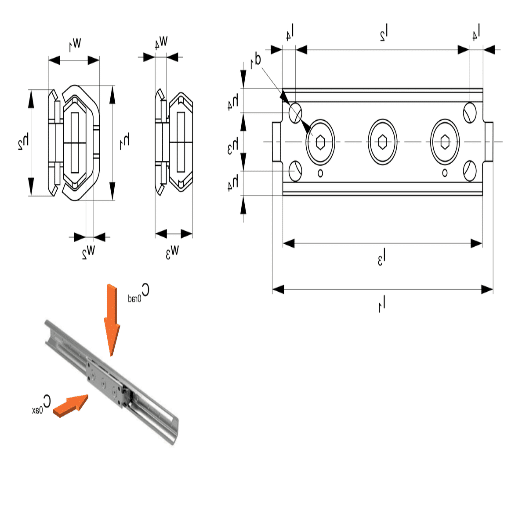

Linear guide and guide rail sizing parameters for best operational results

Choosing the correct linear rail guides ensures precision, durability, and efficiency by determining the correct rail length, width, and size for industrial applications. Based on the specific application, the linear guide rail range should include the full range of travel, including overtravel safety margins. While ultra-long movements require long rails, they are also more prone to deflection when heavy loads are applied; hence, additional supports may be necessary.

Despite the importance of load-bearing capacity and maintaining alignment accuracy, rail width still plays the most important role during the mentioned operations. When the rail is wider, it tends to be more stable. However, if it is too wide, there is excessive bulk and expense, which will probably add to a lesser demand rather than the specific requirements.

Permitting fitting with the design of the machine and respective bearing blocks, as well as the height and profile of the rail, is also a particular dimension. High profile rails are acceptable for heavy loading, on the oher hand compact low profile are most suporior towers to space limited areas. Other than the requirements, setting a specific combination of criteria among the parameters will help reduce wear and ensure long-lasting reliability, especially under dynamic conditions or in high-precision industries.

Material comparisons: carbon steel and aluminum extrusion linear rails

When considering linear rails, carbon steel and aluminum have distinct pros and cons depending on the application requirements. Carbon steel is best known for its incredible strength, rigid structure, and high durability for wear and tear, making it perfect for highly high-load environments that need to be used for a long time. It also provides excellent stiffness that is suitable for reliably demanding applications with high vibrational forces or intricate positioning precision. Unfortunately, this also means it is heavier than aluminum, often resulting in additional treatments like coatings to resist corrosion in moisture-laden or outdoor regions.

Extruded aluminum, on the other hand, is not only light but also offers more significant advantages over carbon steel because it is non-corrosion resistant, allowing the linear guides to be used in areas exposed to water or chemicals. The low weight also makes installation much easier as it alleviates stresses on supporting structures. Most importantly, inbound thin-walled aluminum sections can freely dissipate heat in high-precision setups because of their excellent thermal conductivity. The downside is that extruded aluminum is weaker than carbon steel, which is more prone to deformation under heavy loads or continuous high-impact use.

Research shows carbon steel linear rails can support loads of several tons without significant deflection. At the same time, aluminum extrusions are more useful in scenarios where weight savings are more important than load capacity, which is in the order of a few hundred kilograms. The balance of these materials is selected for the system where its operational need, defined life expectance, and environmental conditions are considered.

Linear bearing block and carriage selection for specific applications

For any given application, selecting an appropriate block and carriage for the bearing, also known as linear bearing, tremendously impacts the efficiency and servos of a linear motion system. Some significant parameters are the bearing load capacity, precision, accelerometer operating environment, speed, maintenance, and other preferences and requirements.

In heavy-duty applications, recirculating ball-bearing carriages are typical due to their high dynamic and static load capabilities, often in the range of several thousand kilograms. They also give better precision, which is required by CNC machines or industrial automation equipment, making the systems that need precision minimal deflection and repeatability. However, lighter operations are ideal, like lab automation or 3D printing, polymer linear bearing carriages, or small units with advanced lubrication features. They provide motion that is both smooth and quiet while reducing weight.

When deciding on a bearing block or a carriage, many factors must be considered, one of the most influential being environmental factors. For example, carriages constructed with stainless steel perform excellently in humid or washdown settings. Other environments, such as cleanrooms, may require specially treated components that do not emit high gas levels.

The correct component will always consider preexisting system requirements, available installation space, intended use, and maintenance services. The product’s life cycles can be maximized if put together correctly while minimizing costs.

How do installation and maintenance affect linear rail performance?

Best Practices to Enhance Rigid Mounting for Linear Guide Rails

Guiding rails are used in machines to ensure that specific tools or components move in designated directions. Based on my experience, correctly developing order steps for horizontal guide rails is crucial in linear guide systems and achieving optimal performance. From a highly defined cutting surface standpoint, contaminations above the metallic surface must be reduced to an absolute minimum because any imperfection will lead to misalignment during the best results cutting. For the best results during installation, I prefer using precision alignment tools, which guarantee that the required tolerances for the particular rail are achieved.

Another best practice I have developed over the years includes controlling the torque applied to the bolts or uniformly distributing it among all fasteners. This ensures that all of them receive the same amount of torque. By doing this, rail distortion is eliminated. Additionally, higher-grade bolts guarantee that any previously secured parts do not loosen while locked due to vibrations over time. My personal experience shows that assuming these values in the instructions improves the outcome, and we have seen improved results in the rail’s performance throughout the entire process.

Finally, I reflect on the guide rail combination with the appropriate base material and its relevance. The base is a vibration-damping material and must be rigid to help absorb forces while the system is operational. During my installation, I pay attention to the correct rail and base interface assembly to ensure no undue stress is placed on the system. In conjunction with regular inspections, I am confident that my actions, along with some routine adjustments as required, will give precision to the operation of the guide rail systems for maximum uptime and efficiency.

Requirements and frequency of lubrication of ball bearing linear systems

Achieving maximum precision and maintaining the system’s functionality and reliability will always start with checks and regular maintenance, like lubrication of linear bearing systems. In my case, it is important that the Lubricants are used to match the components to be used and their conditions. It is best to work with specialty oil or grease of a bearing linear system to reduce friction, damage, and component wear due to cross-contamination. As with every other undertaking, balance is key.

Lubrication through maintenance work is customized and scheduled based on the surrounding working environment of the system, the load, and how frequently it is used. For example, in the case of clean systems with low workloads, I ensure lubrication is applied at least every six months. However, I check and reapply lubrication more often than that – quarterly at a minimum – if the system is exposed to dirt and dust or operates under high loads. At each maintenance rotation, I meticulously dismantle components to clean out any old lubricant alongside other remnants to optimize the new application.

Being this structured allows for increased efficiency, so I make it a point to keep a maintenance log that notes each lubrication interval and checks the condition of the guide rails and bearings. Sticking to a well-defined routine allows for early detection of potential issues with performance or wear that can be addressed and prevents them from becoming bigger problems down the line. Such exercises guarantee that my linear systems achieve operational efficiency and reliability throughout their service life.

Addressing frequent problems with linear rails to improve manufacturing workflows

While addressing linear rail problems in a factory setting, my first step involves checking the rails and bearings for visible wear or damage. Insufficient lubrication or contamination are common issues, leading to pitting, scoring, or discoloration. If any of these issues are noticed, I clean all parts thoroughly before reapplying suitable lubricant and checking that the lubrication schedule meets system operational requirements. Regular cleaning must be part of the system’s Work Procedures to prevent system performance contaminants, such as dust and debris.

Misalignment is another typical problem requiring attention, which could result in uneven wear, binding, and excessive noise during operation. For this purpose, I check the rails’ alignment to ensure that all the fasteners are tight. I use precision measuring tools to align the system and confirm that all parts are perpendicular and equidistant to a given plane along the bearing length. This ensures uniform load distribution on the bearing assembly. Accomplishing the optimal alignment will improve system efficiency and increase the durability of the linear rail system.

If the performance problems do not improve, I check the load and operational conditions. Straining a system’s capabilities and functionality boundaries may lead to inefficient operation or malfunction. In such cases, I first evaluate the application’s needs concerning the specifics of the linear rail system. I may suggest either changing work methods to lessen the strain on the system or increasing the system’s capacity by using a higher-grade solution. These steps help me to prevent these issues from worsening so that the entire system is reliable and optimized in the long run.

Frequently Asked Questions (FAQs)

Q: What are the key advantages of using a THK linear rail system in industrial applications?

A: THK linear rail systems present several essential benefits in industrial use. First, they allow for highly accurate linear motion while maintaining smooth movement even under strong friction due to exceptional load capacity and high rigidity. They are perfect for machine tools and other applications requiring heavy load handling. Further, THK linear rails are remarkably durable as long as they are properly maintained and lubricated, even under challenging conditions, and they can withstand long periods of use. Meticulous lubrication allows these components to maintain their durability. Yet another advantage of these components is their self-alignment capability, which can compensate for minor misalignment that can cause an increase in wear and diminish operational lifespan. They also perform consistently.

Q: What are the differences between LM guides and shaft & bushing systems?

A: LM guides represent a more advanced cleaning technology than traditional shafts and bushings systems. Excellent control is offered by LM guides, along with a higher capacity, greater rigidity, and smooth motions free of friction. Unlike shafts, LM guides have recirculating ball bearings that carry loads on several contact points. This helps to keep the system accurate even in dirty environments where heavy, accurate loads are needed. Moreover, LM guides outperform moment loads and help to achieve predictive linear motion. Despite their high initial costs, installing guides yields more value with extended service life, decreased maintenance, and improved performance.

Q: What are the most common lengths for linear guides, and how do I decide between choosing a 500mm or 1000mm guide or a custom length?

A: Most linear guides come in standard lengths of 500mm and 1000mm, with industrial-grade units starting from 15mm in width and going up to 65mm in steps. When selecting a length, remember to accommodate travel requirements, the dimensions of the LM block, and mounting clearances. Multiple rails can be purchased side by side or at custom lengths for longer travel applications. The 500mm option is the most popular for use in smaller machines or where space is restricted, while 1000mm rails are better suited for larger equipment. Most suppliers offer customization to cut the rails to specific dimensions that match the client’s motion system design requirements.

Q: What is the variation between roller and ball bearings about guideways?

A: Roller and ball bearings used in linear guide systems serve the same purpose but differ in function. Due to their cylindrical shape, roller bearings have a greater load capacity since they provide more contact area with the raceways. This makes them ideal for applications with high loads or in dirty environments. They also offer higher rigidity and have greater strength against shock loads. On the other hand, ball bearings offer smoother operations and less resistive force or friction. Therefore, they are ideal for precision applications. Ball guides are more affordable and need less maintenance for less strenuous tasks. In contrast, roller bearings outperform in industrial settings that require strength and durability.

Q: Why should one use MGN12 or other compact linear rails?

A: MGN12 and the other compact linear rail systems are beneficial in terms of space, considering their slim profile, which allows for the integration of tight spaces that still require precise movement. Even though these systems are compact, they still sustain reasonable load capacity and rigidity in their dimensions. MGN12 rails are handy for 3D printers, small automation equipment, and sophisticated machinery tools with tight spatial requirements without forgiving precision. Their standard customizable patterns and mounting components that can be easily sourced make them affordable and convenient for prototyping and other small-scale productions. Best of all, these systems offer outstanding performance regardless of size.

Q: What are the benefits of anodized treatment to linear rails in industrial use?

A: Anodize treatment improves linear rail functionality in industrial applications. The process improves corrosion resistance regarding the applied environments because anodized treatment applies a protective oxide layer on aluminum components using electrochemical methods. Unlike untreated aluminum, anodized surfaces are more complex, improving wear resistance and prolonging service life. The treatment also enhances electrical insulation, which is advantageous for specific applications. Moreover, anodized surfaces may be dyed in different colors for coding or aesthetic purposes. This surface treatment is helpful in the food, semiconductor, and bio industries since it reduces friction while protecting equipment from chemicals and wear and tear. Such features help maintain smooth operation at all times.

Q: What maintenance must be done to linear and slide rails in the industry?

A: Regular linear and slide rails maintenance is essential for their enduring efficiency. Smooth mechanical action necessitates regular maintenance, which includes lubrication with the oil specified by the manufacturer. Scheduled inspections must include a check for contamination; exposed surfaces should be cleaned, and the guideway must be debris-free. In block linear systems, check that the seals and wipers guarding the sensitive internal elements are operating correctly. Extra protective devices such as bellows or covers may be needed for filthy environments to safeguard the rails. The alignment and tightness of mounting bolts should be checked to eliminate undue wear from loose bolts. Most importantly, listen for unusual noise or resistance during operation, as these are warning signs of failure and should be resolved to reduce expensive wrecks.

Q: What benefits can be derived from heavy-duty applications of a 20mm guide linear system?

A: 20 mm guide linear systems are particularly advantageous in industrial applications because they are larger. With increased dimensions, these rails have a relatively higher load-bearing capacity, which benefits applications with high or significant moment loads. Also, the increased size provides greater structural rigidity, enabling much smoother motion under challenging conditions and enhancing accuracy. Usually, these systems are equipped with more powerful ball or roller bearings that incorporate larger steel balls or rollers, which increases the forces that can be supported and the system’s operational life. In addition, the 20 mm profile is more stable and has deflection resistance, which is crucial for CNC machining and other automation systems. Also, these systems usually enable greater travel distances while boasting increased straightness and parallelism, which is needed in large-scale equipment.

Q: How could I attach a linear rail with 4 bearing blocks to my extruded aluminum structure?

A: Fitting a guide with four bearing blocks requires meticulous design and execution to match an extruded aluminum framework. First, check that your extrusions have mounting interfaces or T-slots matching the rail mounting pattern. Alignment is crucial; we recommend confirming the mounting surface is straight before installation using a straight edge or laser alignment tool. During assembly, the initial step should be to loosely fasten all the components before doing it in a specific order that minimizes distortion. Mounting on four blocks increases stiffness and better load distribution, especially for broader or longer carriages. Anodized aluminum parts may be better if lower corrosion resistance and higher durability are required. Preload the system based on the manufacturer’s guidelines for applications that need a certain degree of precision. Lastly, maintain the reliability of your linear motion system by adding adequate access for lubrication, maintenance, and others, as well as proper cleaning.