‘Power cables’ are the pillars of contemporary technology, enabling our day-to-day devices like smartphones and laptops to function. You must have the right cable for maximum efficiency, safety, and performance. We have compiled a guide to help you choose the right power cords, cables, connectors, and adapters. Choosing suitable power cords and understanding their importance does not need to be complicated. We strive to inform you about each detail so you can make the best choices for your modern lifestyle. In the coming sections, we detail everything covered under technical jargon, from the most recent advancements in the field. So, prepare for a technological infusion while understanding the nitty gritty of power connectivity!

What is a power cable, and How Does it work?

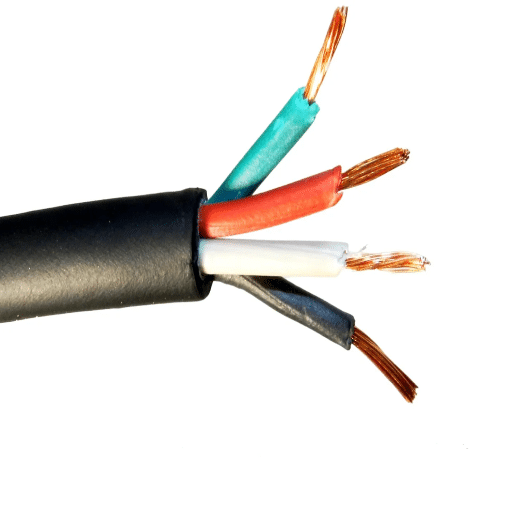

A power cable combines several wires or optical fibers encased in an insulator to transmit electric signals or data between devices. Cables function by forming conductive pathways that allow energy or information to travel from one point to another. Electrical cables utilize power through conductive materials such as copper and aluminum, whereas data cables transmit digital and analog information through electrical signals and light. In addition, insulation minimizes interference, ensuring safety and reliable performance.

Understanding the Basics of Power Cables

Power cables are crucial for transporting electricity safely and effectively. I know they are constructed using conductors like copper or aluminum, as they can transmit electricity from one location to another. In addition to providing reliable and efficient power transport, the insulation surrounding these cables offers protection and reduces interference.

How Do Power Cords Transfer Electrical Current?

Along with transporting over longer distances, power cords effortlessly transfer electrical current between a power socket and the device. The inside of a typical power cord is composed of copper or aluminum, which are good conductors. When the Electrical device is plugged into a power source, Electrical current flows as it moves through the conductive wires to power the Electrical device.

The insulation surrounding the conductive wires addresses safety measures by protecting against electrical interference. It alleviates the risk of short circuits and accidental contact. Modern Power cords do not lack additional safety measures and so come with added protective layers, such as grounding wires. These layers are designed to improve the safety and reliability of electricity flow.

The gauge size of a power cord, based on its distance, determines the efficiency with which the cord can transfer electric current. For high-power appliances, thick wires with lower gauge numbers are ideal as they can carry current with less resistance. Industry standards set some of these specifications to ensure safety and compatibility.

Take copper power cords, for example. Their conductivity is near the 100% mark for the International Annealed Copper Standard (IACS), meaning the copper wires can conduct electricity very well. The high conductivity allows for minimal energy loss during power transport, so electrically connected devices can receive power without wasting energy. Power cords, high-quality conductive materials, and safety insulation can ensure that many devices can be safely and effectively powered.

The Role of Adapters in Power Distribution

Where compatibility is an issue, adapters are critical for effective, streamlined power allocation. They adapt to different plugs, voltages, or regional requirements of specific devices to ensure dependable and effective operation. For instance, plug adapters allow electrical standard devices to attach seamlessly to power supplies within numerous countries with different outlet designs and voltage ranges.

To avoid damage caused by overcurrents or voltage spikes, modern adapters are often equipped with advanced protective features such as surge protection and built-in fuses. Data suggests that global sales of travel adapters, which incorporate voltage conversion functionality alongside plug adaptability, have been growing consistently due to increased international travel. Also, USB adapters have become increasingly popular as numerous models now offer fast-charging capabilities while enabling simultaneous connections of multiple devices. These improvements demonstrate the importance of adapters in residential and commercial power distribution and their ability to power various devices safely and efficiently.

How to Choose the Right Power Cable for Your Needs?

When adopting a power cable, paying attention to the following aspects is critical:

Device Compatibility: Check whether the cable fits your input voltage and current rating.

Cable Length: Choose a length that suits your convenience while balancing signal/power loss.

Connector Type: Ensure that the connector type matches your device’s input, particularly so it connects and holds firmly.

Build Quality: Use durable materials like braided wires or reinforced connectors to ensure long-lasting safety and protection.

Certifications: Look for safety-certified cables, such as UL or CE, that meet the required quality control standards.

With the above factors, you can easily and safely find a power cable that meets your needs.

Factors to Consider When Selecting a Power Cable

While buffing up devices, a power cable bundled with the device is primarily considered. But in my case, I analyze the gadget’s capability range, such as type and wattage, to ensure compatibility before purchase. The cable’s length is another measuring factor for my assembly. Per safety and industry regulations, the materials used must meet set industry standards for the reliability and durability needed. Of equal importance are the cables with a secure, stable connection that provides no problems while in use—this set of deliberations aids in meeting my goals in chip efficiency.

Different Types of Cable Connectors: NEMA vs. IEC

Cables with NEMA (National Electric Manufacturers Association) and IEC (International Electrotechnical Commission) interfacing connectors are utilized in various settings. However, they are poles apart in design, application, and standards.

NEMA connectors cover North America and are guided rigidly by the NEMA organization. Each type of their connectors is built for specific voltage and current electrical demands. You can find them in domestic and commercial electrical devices, such as appliances. For example, one of the most common types is a NEMA 5-15 connector rated for 125 volts and 15 amps. This type is usually meant for computers, TVs, and small devices. NEMA connectors can be referenced with their distinctive prong patterns and shapes that coincide with power needs and are placed for safe and dependable operation.

IEC Connectors, however, have international standards and are used primarily for professional or industrial-grade equipment. One of the most common IEC connectors is the IEC 60320 C13, rated for 250 volts and 10 amps. C13 is frequently used to power desktop computers, monitors, and printers. Value for money – These connectors are valued for their universal compatibility, making them reliable for universal usage. Their compact shape makes them easily integrated into various devices and avoids needing region-specific adaptors.

When choosing between NEMA and IEC connectors, one must consider the regional power standards, voltage, and current rating. Knowing a device’s specifications and the connector type will guarantee safety and efficient operations in various environments.

Understanding Current Ratings and Conductor Material

In electrical engineering, current ratings indicate the upper current limit that a conductor or connector can safely carry without overheating. These ratings depend on factors like the conductor’s material, its cross-sectional area, the type of insulation used, and even the environment’s temperature. The most commonly used conductors, copper and aluminum, have unique traits that serve as advantages and disadvantages for their conductivity and physical properties.

Copper’s enhanced durability and conductivity allow it to carry more current with the same gauge as aluminum. For example, a copper wire of 2.5 mm² cross-section can hold about 24 amps, whereas an aluminum wire of the same size can support around 18 amps. Where weight and cost are significant concerns, aluminum may be suitable because it is significantly lighter and cheaper than copper. Still, a larger size may be necessary to counterbalance its low conductivity.

Understanding the interrelation between the current ratings and the materials used for conductors is crucial to achieving efficiency and performance when devising or selecting an electrical system. Additionally, operating temperature, prevailing conditions, and the overall purpose of the application must also be considered. Following these practices facilitates compliance with safety regulations while prolonging the working life of electrical installations and devices.

What are the key flexibility features of power cords?

Multiple key characteristics determine the flexibility of power cords. Firstly, the material used for the insulation and outer jacket, such as rubber or thermoplastics, enhances flexibility. Secondly, the flexibility of the cord, which can bend and withstand damage, is impacted by the strand count and diameter of the conductors—the higher the strand count, the greater the flexibility. Lastly, the design of the cords, including the length and cross-sectional thickness, strives to balance ease-of-use across the myriad environments and applications in which the cord would be utilized while engineered for durability.

Why Flexibility Matters in Power Cord Design

Flexibility is critical in power cord design, influencing performance and user friendliness. Cords must be highly flexible to enable ease of movement, especially in robotics, medical apparatuses, and portable devices. For example, cords in robotic applications require an unfailing ability to bend and twist repeatedly to ensure uninterrupted operations. Research indicates that cords with high strand counts combined with light materials like TPE (thermoplastic elastomers) or silicone are more flexible, offering bending radii 5 times the cable diameter.

According to industry benchmarks, flexible power cords relieve stress from connections, thus improving their lifespan and safety. For example, flexible cords in industrial applications mitigate the risk of degeneration from repeated mechanical stress, which mitigates electrical failures. Moreover, cords designed with some degree of flexibility can withstand extreme temperatures, making them useful in outdoor and high-heat conditions. This reliability improves dependability, which makes such cords the premier option in harsh situations.

In response to the ever-increasing industrial needs, advanced materials and best-suited shapes are added to modern technology’s non-negotiable safety and durability requirements. Flexibility through power cord design synergizes high adaptability with an unmatched efficiency level.

Top Features that Include Flexible Power Cords

Heat Resistance: Flexible power cords are made to add value even when used in high-temperature conditions. For example, silicone and heat-resistant PVC can withstand 105°C. This makes flexible power cords useful for industrial machines, kitchen appliances, and outdoor equipment that undergo constant heat.

Enhanced Flexibility and Durability: Flexible power cords can bend easily while maintaining strength. Multi-stranded or tinned copper wires and specialized insulating materials ensure these cords can endure constricted bending, twisting, and coiling, which are essential in robotics and portable tools.

Weather Resistance: Flexible power cords that resist oil, chemicals, UV rays, and even water have been developed. Neoprene and thermoplastic elastomer materials make these cords useful outside and in conditions where liquids or corrosive materials can be spilled, making them ideal in the marine, construction, and medical fields.

Custom Lengths and Configurations: Its main advantage is Custom-sized, flexible power cords. Short cords are useful for hand tools, while long, heavy-duty extensions can be adapted for outdoor equipment, meeting all requirements.

Adhering to Safety Standards and Compliance: Power flexible cords with international certifications such as UL, CSA, or IEC Standard ensure a safer and more reliable product. These certifications guarantee that consumers have undergone strict safety checks and performance tests for the peace of mind they need, especially in dangerous surroundings.

Meeting Industry Performance Standards: Advancements in material science have improved the conductivity of flexible cords while reducing energy losses. Features like oxygen-free copper improve transmission efficiency, reducing the resistance and heat generated in high-load scenarios.

Due to innovations aimed at increasing adaptability, performance, and safety, flexible power cords are becoming increasingly vital across industries.

How to Prevent Damage with Flexible Cables

With suitable procedures for handling and upkeep, flexible cables can last longer and function well with safety and security in multiple domains. The following are prevention measures to avoid possible damage:

Avoid Overbending: Cable overbending can negatively impact the performance, leading to wear and tear. Smooth curves should be adhered to, with the minimum bending radius specified by the manufacturer.

Implement Strain Relief: Excessive pulling on the cables can break the internal wires and damage the insulation. Armed with strain relief devices, clamps, and cable glands, securing and distributing mechanical stresses on the provided cables becomes easier, especially in heavy-duty and dynamic work environments.

Protect Against Abrasion: Flexible cables risk facing sharp edges and abrasive surfaces in industrial surroundings. Protective conduits or sleeves for the cables made cut-resistant to physical wear, such as PVC or nylon sleeves, keep the tubes protected from accidental cuts or nicks while enhancing performance.

Avoid Extreme Conditions: Constant exposure to UV radiation, certain chemicals, and extreme temperatures can weaken the cable insulation. Cables with sheathing materials explicitly tailored to face these environmental risks should be opted for. For example, cables with cross-linked polyethylene (XLPE) can fare well in extreme heat, while jackets rated for UV protection protect the wires when used outdoors.

Scheduled Checks and Maintenance: Perform routine checks for bends, breaks, or color changes in the cable jack. Infrared thermography tools and electrical testing equipment can detect overheating and undiagnosed issues, improving safety and reducing downtime.

Following these best practices, industries can decrease failures and enhance reliability. As stated in the industry reports, improper handling is the cause of more than 60% of flexible cords’ failures, which showcases the gap in attention to detail and the need for these measures.

Exploring Different Classes of Power Cables

Power cables are classified into different types based on usage, voltage ratings, and structure. The primary classes include low voltage, medium voltage, and high voltage. Commonly used in residential and commercial settings, low-voltage cables power appliances and lighting systems. Medium voltage cables are found in industrial facilities and utilities to power infrastructure over moderate distances. High-voltage wires, such as those in power grids and major construction projects, are used for long-distance electricity transmission. In other words, each class fulfills a particular purpose and is designed with suitable insulation and protective materials related to its function and environment.

Understanding the Class of Electrical Cables

Several factors must be considered when choosing electrical cables for optimal performance, safety, and reliability. One such factor is the current carrying capacity, which determines how much electrical load a cable can take without overheating. This capacity depends on the conductor material, which can be copper or aluminum, the cross-sectional area, and the environmental temperature of the cable region.

Another essential consideration is insulation type. Different environments require specific insulation materials. For instance, thermoplastic insulations like PVC are typically used for residential wiring, while medium and high-voltage cables prefer cross-linked polyethylene (XLPE) due to its thermal resistance and strength.

Outer sheathing is also very useful in harsh environments. Plastic sheaths, such as polyethylene (PE) or thermoplastic polyurethane (TPU), enable cables to withstand physical attacks, moisture, and chemicals. Armored cables with metallic coverings offer enhanced protection for underground or undersea applications.

The cable’s voltage rating has to match its intended purpose. Low-voltage cables operate below 1,000 volts and are used in homes and small commercial establishments. Medium-voltage cables are suitable for voltages ranging from 1,000V to 35,000V and for linking substations or industrial plants. High-voltage cables can support transmissions greater than 35,000V, vital in the power grid’s operations.

Lastly, the quality of materials, installation, and maintenance determines the longevity of the cables. Compliance with international standards such as those from the International Electrotechnical Commission (IEC) or the National Electrical Code (NEC) ensures that performance regulatory requirements do not compromise performance.

Which Class of Cable is Best for Heavy-Duty Applications?

For demanding tasks, EPR (Ethylene Propylene Rubber) insulated cables, XLPE (Cross-Linked Polyethylene) cables, and armored cables are the best picks due to their unmatched toughness and performance. Capable of withstanding harsh environments, these heavy-duty cables are ideal for use in construction or mining.

EPR insulated cables can handle thermal extremes from -40°C to 90°C, which makes them exceptionally versatile. These cables also do not absorb moisture. In addition, they are resistant to chemicals and ozone, making them suitable for industrial and outdoor applications.

Due to their strength, XLPE cables can withstand high voltage levels even under extreme conditions, making them ideal for use with heavy machinery and power distribution networks. These cables can support up to 400kV of voltage and have better resistance to abrasion, chemical exposure, and water, further improving their lifespan.

Because of their extra protection, armored cables are ideal for use in situations or places prone to physical abuse and damage. The steel or aluminum armor shields the inner conductors, making them durable for mining, construction, and underground work. They also aid in compliance with IEC and NEC standards, further strengthening their use in harsh operations.

Choosing the correct cable for heavy-duty applications requires evaluating voltage capacity, environment, and safety regulations. Furthermore, utilizing manufacturer data guarantees that the insulation type, thermal resistance, and mechanical strength are appropriate for the operational needs.

Custom Class Options for Special Applications

Custom-class cables address the performance demands of highly specialized industrial applications, enhancing performance and ruggedness in protective environments. Such cables are designed to cope with operational requirements like extreme weather conditions, harsh mechanical stress, or exposure to hostile chemicals.

For example, high-temperature range classified cables may have cross-linked polyethylene (XLPE) or polyimide insulation, which permits an operating temperature of 250 degrees Celsius. Furthermore, listed flame retardant low-smoke halogen-free (LSZH) cables are suitable for applications requiring fire safety and low toxic substance emissions, such as public transport systems or congestion-prone buildings.

To withstand extreme mechanical stress, armored cables with reinforced steel wire or tape provide increased protection from physical damage and are suitable for underground or subsea installations. Marine-certified cables are built using anti-corrosive materials to endure destructive moisture and saltwater for long periods. Reverse radiation cables are manufactured for use in nuclear power plants.

Picking a custom class cable requires consideration of international standards like IEC 60092 for ships and NEC Article 400 for flexible cords due to safety and compliance. To meet specific operational requirements, the custom cables undergo extensive testing for abrasion resistance, dielectric strength, and environmental compatibility. These custom options enhance system dependability and minimize long-term maintenance expenses, which is crucial for specialized industrial systems.

Common Applications of Power Cables in Everyday Devices

Appliances and devices rely on power cables daily for easy access to electrical power. Household appliances such as washing machines, refrigerators, televisions, and microwaves rely entirely on power cables to supply electricity. Modern gadgets like smartphones, laptops, and tablets require power cables for safe and convenient charging. These cables function reliably, delivering safe electrical connections in homes and commercial areas.

Using Power Cords for Laptop and Computer Power Supply

The power cords of laptops and computers have become essential for their smooth running. They ensure the required levels of voltage and current needed to keep your system operational. In the case of modern-day laptops, the power adapters are meant to convert the alternating current (AC) from wall sockets into direct current (DC) that most laptops or computers require.

To maximize the performance of your device, power cords, like any other accessory, need to be carefully selected, considering their voltage and amperage specifications. For example, many laptops run on a voltage between 19V and 20V with a current between 2A and 4.5A. Some newer laptops also accept USB-C power delivery and can be consumed with higher wattage of up to 100W, allowing much faster charging for supported users and powering more energy-intensive devices. If the wrong power cord or adapter is used, your device could stop charging altogether. Even worse, the device may be damaged.

As I stated before, quality is equally indispensable. Power cords with short circuits cannot protect against overload and are proven to be heat—and fire-retardant. These features, in one way or another, reduce the overheating of power supplies or could even lead to electrical fires, which can damage the appliance attached. Furthermore, the power cord should be kept in good condition, avoiding fraying, bending, and water to ensure safety.

Thanks to Desk Tech’s pioneering efforts, some brands now include practical features such as detachable cables and eco-friendly designs, which reduce power waste and make the cords easier to adapt. If users invest in a reliable and compatible power cord, it will prolong the lifespan of their laptops and computers and ensure their functionality operates safely and efficiently.

The Role of Power Cables in Home Electrical Systems

Modern homes rely on power cables to provide electricity to different appliances and ensure that power is transferred correctly and safely. All devices that consume power need current supplied through wires while maintaining the absolute safety standards required to avert electrical threats. With rapid advancements of modern cables, factors such as insulation, thermal reliability, efficiency of the conductor, and even the notes of contemporary skipping rope can all aid in the reliability of the newest cables.

Refrigerators, microwaves, and even chargers can all be found in an average American household, and as per the most recent statistics, more than 30 appliances are present. This highlights the endless versatility that quality construction cables have when it comes to electrical loads. Unique to residential settings, cables such as armored leads boast unrivaled protection for outdoor use, where safety risks are heightened, and even non-metallic sheathed cable, which is perfect for internal wiring, are examples of widely used types of construction cables.

Purchasing cables with industry certifications reduces the risks of fire caused by faulty wiring, improves energy efficiency, and prolongs the lifespan. Furthermore, breakthroughs such as flexible flat cables and heat-resistant insulation technology enable households to manage complicated wiring more safely and efficiently in terms of space. Along with meeting the day-to-day energy needs, modern power cable technologies are essential to promote eco-friendly measures as residential properties shift to renewable energy alternatives and integrated smart grids.

How Power Cord Splitters Help in Efficient Power Distribution

In households and workplaces where there is a high demand for power sources but the number of outlets is limited, power cord splitters become essential accessories. These devices ensure energy is supplied to the outlets efficiently without unnecessary wiring or expensive installations.

The ability for power cord splitters to get rid of clutter is one of the significant perks they offer. This alleviates the use of multiple extension cords and adapters, which helps ensure that workspaces remain organized, and for safety purposes, the chances of electrical hazards are much lower. Industry studies suggest that organized wiring with splitters can reduce electrical dangers like overheating and circuit tripping by 30%. Power cord high-quality splitters also ensure performance reliability with multiple devices due to overload protection, an essential safety feature that strappers design into their products.

Like everything else, modern power splitters are evolving; now, they can work with energy-efficient appliances and even renewable power systems. Some models come with surge protection and built-in USB ports. In our hyper-connected world, there is a rising demand for multifunctional products. In addition, studies have shown that strategically using power splitters can cut down on waste. This is because power splitters have innovative energy management systems that turn off energy for devices not in use. This innovation benefits users because it saves money and helps reduce energy consumption.

Frequently Asked Questions (FAQs)

Q: What is an AC power cord?

A: An AC power cord is a cable used to connect electronic devices to an alternating current (AC) power source. It typically consists of electrical conductors that transmit power from the wall outlet to the device.

Q: What is a C14 connector?

A: A C14 connector is commonly used with computer power cords. It is typically found on a power cable that connects to a power supply unit or equipment like servers and scanners.

Q: How does a computer power cord differ from other power cords?

A: A computer power cord is designed to supply power to computers and related peripherals. It often features connectors like C14 or C19, which are compatible with computer equipment.

Q: What is the significance of 18 AWG in power cables?

A: 18 AWG refers to the American Wire Gauge standard for the thickness of the electrical conductors in the cable. It is a standard gauge for power cords used in home and office electronics, balancing flexibility and current capacity.

Q: What are NEMA 5- 15P and NEMA 5- 15R connectors?

A: NEMA 5-15P is a standard plug connector used in North America, while NEMA 5-15R is the corresponding socket or receptacle. These connectors are commonly used in household and office power cords.

Q: Why would someone use a 3ft power cord?

A: A 3ft power cord is often used when the electronic device is close to the power outlet, minimizing cable clutter and ensuring efficient power delivery.

Q: Can power cords like C19 and C20 be used in hospitals?

A: Yes, power cords with C19 and C20 connectors can be used in hospital settings for medical equipment. However, ensuring they meet specific safety and regulatory standards for medical use is crucial.

Q: How can a power cord extend the reach of a device?

A: A power cord can extend the reach of a device by providing additional length between the device and the power source, allowing more flexibility in equipment placement.

Q: What should be considered when selecting a power cord for a server?

A: When selecting a power cord for a server, consider the type of connectors (such as C14 or C19), the length of the cord, the wire gauge (like 18 AWG), and compatibility with the server’s power requirements.

Q: Why might a power cord have a connector on one end and a different connector on the other end?

A: A power cord might have different connectors on each end to connect devices with specific input and output power requirements, facilitating compatibility with various types of equipment.