‘Portable diesel generators’ are the go-to solution for a steady and dependable power supply because of their versatility in catering to multiple requirements. Whether you are prepping for emergencies, powering tools in remote job sites, or fueling equipment during outdoor events, diesel generators provide durability, efficiency, and portability all at once. This guide offers all the insights necessary to choose the right portable diesel generator to best suit your needs. From understanding the features and benefits to practical maintenance and usage tips, this article will provide the essential information needed. Learn why professionals and homeowners trust portable diesel generators for unmatched reliability.

What is a Portable Diesel Generator and How Does it Work?

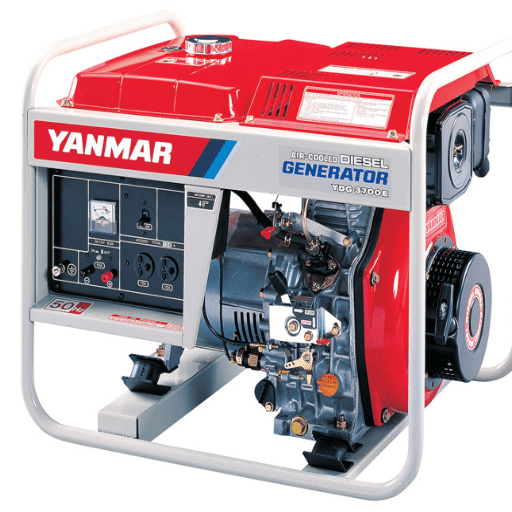

A portable diesel generator is a small, movable device that generates electricity with a diesel engine. It functions by changing the chemical energy contained in diesel fuel into mechanical energy, which an alternator changes into electrical energy. These generators are made to be convenient and provide energy to devices, gadgets, or tools in remote places where electricity is not available. Diesel-powered generators are durable and fuel-efficient, making them reliable for all temporary and emergency power situations.

Understanding the Portable Diesel Generator Mechanism

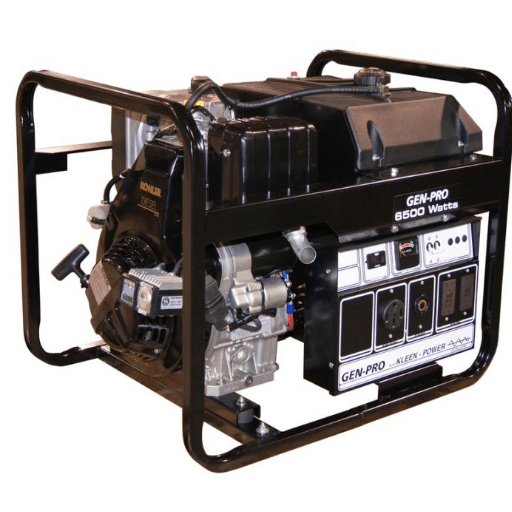

Diesel generators, like portable diesel generators, use an internal fuel-burning engine and an alternator that generates electricity. The diesel engine turns on to produce fuel with a mechanical substance, then turns the alternator machine to create an electric current. Generators are usually found in different sizes. The smaller ones have 3,000 watts, which can be used for household appliances, while the bigger ones are greater than 10,000 watts. The bigger ones are usually utilized in industries or construction sites.

A diesel generator’s key benefit is its ability to efficiently fuel engines. Most portable diesel units effectively use energy and turn approximately 40% of fuel fire power into mechanical power. With this low energy expense, diesel units are more suitable for long-term usage than gasoline-powered appliances. Up-to-date transported diesel generators have modern equipment like direct fuel injection systems, which automatically improve the fuel’s atomization and combustion; this enhances the unit’s performance while reducing emissions even more.

Furthermore, these generators have additional safety features such as automatic low-oil shutdowns, which protect the engine, and overload protection devices, which safeguard the connected apparatus. Modern designs often incorporate quieter operations using noise reduction mechanisms like mufflers and soundproof enclosures. Thus, diesel generators can serve as portable and versatile solutions for energy demands while combining practicality and technological innovations.

The Role of Diesel Engine in Power Generation

Diesel engines are essential to dependable power generation because they serve numerous sectors. Their fuel efficiency and power capacity suit both standby and primary power applications. The fuel-efficient modern diesel engines used in power generation are high-performing, some achieving fuel efficiency of nearly 45%. This makes them optimal for industries where reducing operational costs is critical.

Moreover, generators powered by diesel engines (gensets) range from small-scale units producing a few kilowatts to large-scale systems capable of several megawatts. For instance, industrial-grade diesel generator sets have a typical output range of 250 kW to 3 MW, supporting heavy industry, hospitals, and data center applications that require reliable power without interruption.

Quick start-up times, often reaching full operational capacity within 10 seconds of activation, are advantageous for critical applications such as emergency backup systems. These diesel engines are also constructed to operate under extreme heat and sub-zero temperatures, enhancing adaptability.

These engines have significantly improved their emissions reduction. Modern diesel engines, with Tier 4 compliance regulations and exhaust after-treatment systems, emit nitrogen oxides (NOx) and particulate matter at lower rates than older models. Considering reliability, technological improvements, and the ability to scale, these diesel engines remain one of the primary solutions in power generation worldwide.

How Portable Diesel Generators Compare to Other Power Solutions

Portable diesel generators come out for numerous reasons when weighing options like solar panels, batteries, or gasoline generators. Their unmatched reliability and efficiency make them the preferred choice for households and businesses worldwide.

One of the most notable features of portable diesel generators is fuel efficiency. Compared to gasoline generators, diesel engines consume far less fuel. Furthermore, the durability of these generators ensures a longer lifespan, typically surpassing 10,000 hours of operation with proper maintenance.

Unlike renewable energy sources like solar panels or battery storage, diesel generators excel in situations requiring uninterrupted operation or high power output. Portable diesel generators are easily powered without being affected by environmental constraints, making them perfect for remote locations where steady electricity is needed. These generators are popular during off-grid construction projects and in disaster recovery situations.

Also, the latest developments in portable diesel generators include features aimed at reducing the generator’s impact on the environment, such as emission control systems compliant with Tier 4 and noise reduction designs. These systems provide greater operational efficiency than older generators or other less efficient options.

While gasoline generators tend to be cheaper and smaller, their weight is not economical when considering fuel costs and requires better maintenance. Diesel engines, on the other hand, are more powerful and built to endure heavy loads over extended periods, increasing their usefulness for commercial and industrial problems.

In the end, portable diesel generators outperform various alternatives when dealing with demands for steady and reliable energy, and offer a dependable, versatile, and cost-effective solution for a diverse range of power requirements.

What are the Key Features of a Portable Diesel Generator?

All of these features make portable diesel generators efficient and super reliable. They have powerful engines with fuel consumption better than petrol generators, robust construction for durability even in harsh conditions, and are designed for heavy-duty operations. Many models have advanced and automatic features such as voltage regulation, low oil shutdown systems, and noise-reducing capabilities that enhance operator comfort. They provide easy control panels, versatile mobile designs, and accommodate various power demands for residential and commercial use.

Exploring Silent Designs for Noise Reduction

Many companies are focusing on designing quieter portable diesel generators to mitigate the effects of noise pollution in residential and commercial areas. Modern generators feature state-of-the-art noise reduction technologies, such as acoustic insulation, tailor-made mufflers, and anti-vibration systems. For example, some models effectively lower operational decibel levels by 30-45 decibels using double-walled casings filled with sound-absorbing materials.

Research indicates that modern silent generators can operate at noise levels between 50-60 dB, the level of an everyday conversation, while traditional models exceed 70-90 dB. Enhanced communication features, such as variable-speed engines, can reduce unnecessary noise, changing the power output to match the load demand instead of running at full thrust ventilation. Sound is not the only thing enhanced; fuel efficiency and overall lifespan also increase.

The need for quieter generators pushes innovations to find the right balance between performance and silence. Many new designs are focused on coping with urban noise restrictions and meeting legal noise limits without compromising power to ensure suitability for multiple applications. Silent generators are now the go-to solution for power needs where minimal environmental impact is a priority.

Importance of Durability and Reliability in Generator Selection

When choosing a generator, dependability and trustworthiness are critical components that affect performance and overall value, like cost. A dependable generator helps absorb extreme weather conditions, very low or high temperatures, dust, and even humidity, which is required in construction, agriculture, and healthcare sectors. For example, industrial generators are made of advanced engineering, combining strong materials to operate efficiently for over 10,000 to 30,000 hours with proper servicing.

Dependability becomes more critical in generators needed during emergencies or for continuous use. Research indicates that nearly 70% of people using generators depend on consistent runtime and fuel reliability as deciding factors. Auxiliary start features, real-time oversight, and overload protection mechanisms significantly improve reliability over uninterrupted power control. Users investing in generators manufactured with superior components will experience fewer breakdowns and reduced cost in maintaining work during downtime, maximizing productivity.

How Automatic Control Enhances Operation

Harnessing the benefits of modern technology, the new generators come with Automatic Control Systems (ACS), which provide the generator’s ease of use, reliability, and operational efficiency. Advanced microprocessors and sensors measure critical factors like load, temperature, oil pressure, and fuel level. For example, automatic load balancing permits fuel consumption free-power output to the extent of demand, extending the components’ life. Such generators are known to improve efficiency and cut fuel consumption by fifteen percent with the integrated automatic control systems. This reduced fuel usage means better economics and environmental stewardship.

Intelligent real-time diagnostics integrated into these control systems allow users to avert costly breaks with timelier actionable insights. Industry studies have found that predictive maintenance alongside automatic controls lowers the overall maintenance-related downtime by thirty percent. Automating generator controls further enhances reliability through features such as remote shutdown during overloads and other unsafe operating conditions. Intelligent automation optimizes renowned generator performance while cost, value, and overall lifecycle are well catered for, making the generators ideal for commercial and residential use.

How to Choose the Ideal Portable Diesel Generator for Your Needs?

When purchasing a portable diesel generator, remember the following: Check the power requirements first. Consider the devices you plan on using together to determine your power usage. Remember, the generator’s wattage should meet or exceed the total power you require. The generator fuel consumption should fall within your intended operational timeframe to eliminate the need for regular refueling. Also, the runtime and fuel efficiency should be examined. Before purchase, consider the expected duration of use in terms of tank capacity and efficiency, ensuring they don’t require constant refueling. Safety features include automatic shut-offs, overload protection mechanisms, and backup systems. Budget and brand trustworthiness are other contributing factors. Identify models that align with your wallet while still falling within trusted brands renowned for excellent reliability or after-sales support. Make sure to select options that improve the portable nature of the device, such as a compact design, sturdy handles, wheels, effortless transportation, and lightweight. Noise levels are also worth considering. Ease of use in residential/noise-sensitive areas while preserving sound quality improves the overall user experience.

Assessing Your Power Needs and Output Requirements

Understanding your power requirements is essential when buying a portable diesel generator, as it helps you consider how it will be used. Begin by listing the items and their corresponding wattage. For example, a refrigerator would use between 600 and 800 watts. A microwave would usually consume anywhere from 1,000 to 1,500 watts. Remember that some devices, like air conditioners and power tools, temporarily surge over their running wattage (2x-3x) at their starting phase.

After determining your wattage needs, look at the generator’s rated and maximum power. A generator’s continuous wattage is its rated power, while the maximum power is the short surge of energy supplied to handle the start-up needs. The generator’s rated output can be set at 3,000 watts for light to medium-duty work with a max of 3,500 watts. This would also mean the 3,000-watt-rated unit with a 3,500-watt peak output can perform light and medium-duty work.

Also, consider the applications you have in mind and whether you want single-phase or three-phase power generation. Single-phase generators are suitable for residential and smaller commercial uses, while three-phase models would be required for larger industrial fuelled equipment.

It’s also essential to include fuel consumption and runtime when evaluating your power needs. Many modern portable diesel generators, depending on the model, have a fuel efficiency rate of 0.25 to 0.6 gallons per hour at half load. Generators with larger fuel tanks, from 4 to 10 gallons, can, under optimal conditions, provide 8 to 24 hours of runtime. This gives them fuel efficiency during low power demand periods, which reduces the need for refueling.

These factors will help the generator perform optimally and be tailored to the customer. They will also help streamline performance. A smooth operation enhances everything from generator life expectancy to service efficiency.

Understanding Fuel Efficiency and Diesel Fuel Consumption

Fuel efficiency is a key consideration when assessing diesel generators since it directly relates to cost and their economic and environmental impact. When comparing different types of engines, diesel engines stand out. Compared to gasoline engines, diesel engines have a fuel efficiency that is 20-30% greater, attributed to the more efficient work done on diesel fuel and its ignition process.

A diesel generator will, more or less, burn through 0.4 to 0.6 gallons of fuel every hour for every 10 kW of output with the generator rated at around 10% load or slightly more, depending on make and model. A good example is a 20 kW generator that runs on 75% load and burns roughly 1.2 gallons of diesel proportionately each hour. Generators are more efficient when running closer to their optimal load, usually 50 to 75%.

These two broad areas feature several sub-areas to consider, namely temperature and altitude, along with the last time the generator was maintained. Simple things like timely oil changes and air filter cleans can enhance fuel efficiency. Newer generator models also come equipped with improved fuel management systems that minimize fuel wasted during combustion, improving performance. By narrowing down to specific generational and business usage policies, tailored strategies can be designed and implemented to help bridge the gap between accessible fuel reliability and financial savings.

Considering Mobility and Trailer Options

Regarding mobility and trailer options, selecting a generator for operations requiring relatively frequent relocations is essential. This class of mobile generators provides excellent mobility and dependable power delivery to various areas. Master manufacturers report that portable generator trailers are now made with reinforced steel frames and weather-resistant coatings, allowing them to endure harsher weather conditions.

To illustrate, single-axle lightweight trailers are the best option for lightweight smaller generators because they are easier to tow. Heavy-duty double-axle trailers are often used for larger industrial-grade generators since they improve load distribution and overall transport stability. Locking mechanisms, integrated brakes, and adjustable hitch couplings further increase safety during transport.

Considering mobility needs means assessing the generator’s total weight and the trailer’s load capacity. Weight limits and vehicle class must match the generator specifications to avoid poor performance and overloading. Considering this lens, users’ requirements are met with flexible and robust generators regardless of the environment.

What are the Benefits of Using Portable Diesel Generators?

The varied uses of portable diesel generators allow them to remain an essential power solution in many situations. These generators outperform others in efficiency and reliability, particularly in remote locations, during power outages or emergencies. The highly energy-dense nature of diesel fuel ensures consistent operation, as it is often more easily available. Portable diesel generators are less maintenance-intensive and more durable than other fuel types, increasing cost-effectiveness. The frequent changes in construction sites and emergency response scenarios require easy deployment and transport, provided through the portability of diesel generators.

Providing Emergency Backup Power

In critical situations, emergency backup power is a cornerstone of maintaining operations during unexpected power outages. Homes, businesses, industrial facilities, and hospitals depend on these power sources for uninterrupted operations. They also require backup generators during medical procedures and surgeries. Countering the growing 64% increase in power outages caused by extreme weather and aging infrastructure, portable diesel generators provide swift restarts alongside high energy outputs to power essential HVAC units, chillers, medical equipment, and communication networks.

Recent technological developments enhance the performance and eco-friendliness of diesel generators. Integrating advanced exhaust after-treatment systems and fuel injection processes has decreased emissions through more rigorous policies. Moreover, modern systems interface with intelligent monitoring systems, providing real-time diagnostics and automated checkups to guarantee functionality during emergencies. For towns, businesses, and individuals, having dependable backup power sources helps reduce the risk of prolonged power outages.

Applications in Construction and Industrial Settings

Back-up power systems are vital in construction and industrial settings because they ensure power is available where and when needed. They also ensure that activities that require power can be done safely and smoothly. In construction, backup power aids the function of essential equipment like power cranes and drills. This helps the company stay within time limits and avoid cost overruns, which are commonly associated with modern-day construction projects and construction cancellations. According to industry reports, modern construction diesel back-up power generators are usually considered the most effective solution within the sector because they endure wear and tear over time. They also provide reliability and functionality.

Uninterruptible power is equally important in industrial settings to avoid process halts. Research indicates that power interruptions could have devastating effects on industrial facilities by incurring ‘downtime’ costs, which, depending on the sector, could be unbelievably high during some activities such as automotive or electronic device manufacturing. Bringing operations back during downtime has been simplified with modern-day switches that seamlessly integrate backup power. This prevents sensitive operations from being lost as a result of time delays.

In addition, sustainability alternatives, including those with solar power integrated into batteries, are rapidly gaining popularity. Not only do these solutions decrease reliance on fossil fuels, but they also aid compliance with regulations designed to enhance energy utilization in manufacturing and construction processes. There is an increasing acknowledgment that dependable backup power infrastructure is instrumental in operational success in both demanding situations.

Advantages in Disaster Relief and Infrastructure Projects

Renewable energy resources like solar power and battery storage systems offer dependable, resourceful, and sustainable power solutions in critical environments, which makes them especially useful in disaster relief and infrastructure projects. In times of disaster, these systems provide immediate energy deployment capabilities in places where power grids may be damaged or absent. For instance, portable solar units have been deployed to provide medical and communication equipment with power for hurricanes and earthquake-affected remote regions to deliver essential services.

In addition, during the execution of infrastructure projects, especially in remote or rural places, reliance on expensive and environmentally harmful diesel generators can now be mitigated using renewables. One study demonstrated how installing solar and battery systems at construction sites can lead to a 40% reduction in fuel expenses, not to mention the significant decrease in emissions of greenhouse gases. Sustainable objectives are further attained, especially now that worldwide efforts are geared towards curbing carbon emissions in key industries. Additionally, the versatility of renewable technology is attractive, enabling systems to be increased or decreased according to the energy demands of specific projects, providing economic and operational efficacy.

How to Maintain a Portable Diesel Generator?

Regular Inspections—Check the generator for excessive wear, dangerous leaks, and damage. Inspect fuel lines, seals, and connections for proper operation.

Cleaning the Air Filter—Replace or clean air filters according to the manufacturer’s guidelines; failure to do so could impair operational efficiency.

Change the Oil and Filters—Following the maintenance schedule is critical when replacing the oil and fuel filters to avoid unnecessary wear on the engine.

Monitor Fuel Quality—Maintain a proper storage environment to protect the generator from contamination by dirty diesel fuel. Fuel Quality needs to be top-tier.

Inspect the Battery—Ensuring the battery is charged can avoid startup problems due to under-charging or corrosion issues.

Run Periodic Tests—Identify issues early on by running the generator periodically, even when unnecessary. This helps keep the engine in good working order, too.

Follow Manufacturer Guidelines. As the user manual states, look up the maintenance routines and dates specific to the generator model.

Proper maintenance is essential for portable diesel generators to ensure dependability, reduce the chance of breakdowns, and extend their usable life.

Regular Filter and Oil Changes

It is crucial to consistently change the oil and filters to keep a portable diesel generator running smoothly and efficiently. Strategic oil changes can prolong durability by letting the oil keep the engine properly lubricated and reducing friction and overheating. Filters can also prevent dirt, debris, and fuel impurities from contaminating the engine.

Following traditional recommendations, the oil in the engine can be changed after an operation period of 100–200 hours, depending on the model and usage frequency. For checkups, air and fuel filters have to be checked and possibly replaced every 200-500 hours, too. Following these recommendations can prevent decreased efficiency, increased engine wear and tear, or complete system failure.

Using proper grade oil enhances efficiency and performance. For portable diesel generators, semi-synthetic or synthetic oil is advised. Best practices recommend using OEM filters for correct dimensions and ensuring filtration. Follow the set guidelines and filters to prevent early wear and guarantee proper function during times of need.

Ensuring Optimal Performance with Routine Checks

Routine inspections are essential to ensure that a diesel generator operates seamlessly. One important step is checking the fuel system, as diesel fuel tends to go bad over time, resulting in contamination and clogging. A study indicated that distinguishing between a humid environment and microbial growth in a tank’s fuel is a concern for many. Thus, blockages must be cleared, and fuel systems must be cleaned periodically to maintain uninterrupted, smooth operation.

Displaying the correct levels and quality of coolant is yet another critical task. Overheating an engine is one of the leading causes of damage, so maintaining the proper coolant level is key. Additionally, an expert claims that continuously testing coolant over six months powerfully establishes the optimal temperature that needs to be maintained.

Air filter checkups can also greatly determine the overall performance of the equipment. Tight filters can cut airflow and limit efficiency, increasing fuel consumption. It is advisable to carry out inspections every 100 and 250 operational hours. If the examined filters detect excessive dirt and wear, replacing them becomes a requirement.

Finally, don’t neglect the batteries. The beginning phase of a battery-powered generator consumes a lot of energy; therefore, batteries must be checked for corrosion and tested regularly. Industry standards recommend performing a voltage and health check on the battery every three months to ensure reliable performance during crucial periods.

Integrating these steps into proactive maintenance plans significantly reduces the likelihood of unexpected failures and prolongs the generator’s life.

Troubleshooting Common Generator Issues

During every generator troubleshooting session, I check the primary components, such as fuel and oil levels and connections. When the generator won’t start, I inspect the battery for corrosion and check the charge. Also, I check the load and the generator’s capacity for power output cases and assess the condition of the spark plugs and air filters. Most issues can be resolved after regular maintenance and performing these straightforward diagnostics. With these checks, I can identify problems quickly.

Reference Sources

Here are summaries of the key findings and methodologies from the recent studies on portable diesel generators:

1. Fuel Saving on Diesel Genset using PV/Battery Spike Cutting in Remote Area Microgrid

- Key Findings: This study focused on integrating photovoltaic (PV) systems and battery storage with diesel generators (DG) in remote microgrids. Using an Energy Management System (EMS) to cut load spikes reduced the required DG capacity from 80 kVA to 42 kVA, leading to a 50% reduction in fuel consumption. The hybrid system demonstrated significant cost savings and sustainability improvements.

- Methodology: The research involved installing an innovative microgrid system in a remote island, combining PV, battery storage, and DG. The EMS managed load spikes and optimized energy distribution, supported by real-world experiments in Raja Ampat, Indonesia2.

2. Optimal Design of an Enclosure for a Portable Generator

- Key Findings: This study explored the design of noise-reducing enclosures for portable generators. The research highlighted the importance of acoustical properties in enclosure design to minimize noise pollution effectively.

- Methodology: The study applied theoretical models and experimental validation to assess enclosure insertion loss. It incorporated engineering principles to optimize the design for consumer needs 3.

3. Performance Improvement of a Portable Electric Generator Using an Optimized Bio-Fuel Ratio

- Key Findings: The study evaluated the performance of a portable generator using bio-fuel blends (ethanol, butanol, and methanol) with gasoline. It found that a 10% ethanol-gasoline blend improved engine performance by 6%, while a 20% butanol-gasoline blend increased performance by 8%.

- Methodology: Experiments were conducted using a single-cylinder two-stroke engine and a generator. The study measured electrical output under various bio-fuel blending ratios and load conditions, demonstrating bio-fuels’ potential to enhance generator efficiency4.

These studies provide valuable insights into improving portable diesel generators’ efficiency, sustainability, and usability through innovative technologies and alternative fuels.

Frequently Asked Questions (FAQs)

Q: What are the key features of portable diesel generators?

A: Portable diesel generators feature a durable motor, stable power output, and seamless connectivity options, making them ideal for home use and larger applications such as mining.

Q: What types of portable diesel generators are available?

A: Portable diesel generators come in various types, including those designed for home use, industrial applications, and specific models like the 10kVA generator, which is popular for its balance of power and portability.

Q: How does a 10kVA portable diesel generator benefit home use?

A: A 10kVA portable diesel generator provides ample power for critical home appliances during outages, ensuring a stable and reliable power supply. It’s compact and powerful enough for home use to run essential systems.

Q: What should I consider when purchasing diesel generators for sale?

A: When purchasing diesel generators for sale, consider the generator’s power output, fuel efficiency, noise levels, and shipping options. It’s also essential to assess the manufacturer’s warranty and support.

Q: Why choose a Kubota portable diesel generator?

A: Kubota portable diesel generators are renowned for their efficient motors and long-lasting performance. They offer reliable power and low emissions and are designed for home and industrial use.

Q: Can portable diesel generators be used for mining operations?

A: Potable diesel generators are ideal for mining operations due to their large fuel tanks and robust production capabilities. They offer stable and continuous power in remote locations.

Q: Is rental a viable option for portable diesel generators?

A: Renting portable diesel generators is viable for short-term needs or events. It offers flexibility and access to high-quality generators without the commitment of a complete purchase.

Q: What are the advantages of diesel generators over other types?

A: Diesel generators are more fuel-efficient, have longer lifespans, and provide stable power output compared to gas generators. They are ideal for both home use and industrial applications.

Q: How can I ensure seamless connectivity with my portable diesel generator?

A: To ensure seamless connectivity, choose a generator with multiple outlet options and compatibility with different devices. Regular maintenance and using the correct cables and connectors will also help maintain reliable connections.