Installing a lightning protection system is worth the effort because it reduces potential anxiety and danger. Perilous regional storms can set off fierce lightning that starts fires or collapses critical parts of a house’s electricity, making repair costs for homeowners extravagant. This guide highlights the installation of copper lightning rod systems, which have proven effective in protecting property. I will explain how lightning rods contain high voltage currents, how they are durable copper, and how to install a lightning rod system in your home. This material will greatly benefit anyone looking to add safety or prepare for an oncoming storm. It is time to take action. Find more info now!

What is a Copper Lightning Rod and How Does It Protect Your House?

How Copper Lightning Rods Divert Lightning Strikes

Lightning can have destructive consequences, but lightning rods can prevent this. Built using copper at the top of the structure, the lightning rods act as excellent pathways for lightning to be systematically channeled to the ground via a conductive network. This ensures that the electric energy does not damage the property, cause a fire, or endanger the people inside.

Copper has distinguished features that make it suitable for lightning rods, such as resistance to damage, outstanding electrical conductivity, and long lifespan. In addition, copper can withstand changing environmental conditions. Research has concluded that copper can easily dissipate the energy from lightning strikes while cutting down on danger incidents. Mounting a copper lightning rod system will also allow homeowners to protect their homes from the risks that arise during thunderstorms, ensuring calm and peace.

Evaluating copper copper-clad lightning protection systems side by side

When choosing between pure copper and copper-clad lightning protection systems, knowing each system’s distinctive features is crucial for the proper selection.

Systems Made of Pure Copper: This brand of lightning protection systems is known for its durability and unrivaled conductivity. Copper’s ability to conduct electricity helps redirect lightning and send it safely to the ground. In addition, pure copper parts do not corrode easily, meaning they perform better, even during regrettable environmental conditions. Ironically, because of their enduring quality and material purity, these products come with an expensive initial cost, making it difficult for users on a strict budget.

Systems Made of Copper-Clad: These systems have a better outer layer than the core, which is conductive steel. Though these systems are not as cost-friendly as pure copper, the steel core increases other factors, such as conductiveness. This makes the system less prone to physical damage during installation or with time. Moreover, good electrical performance, together with reasonable corrosion resistance, is guaranteed by the copper outer layer. Affordability and durability in moderately demanding systems are the main reasons copper-clad systems are more favorable.

Performance and Analysis: Supplied with conductivity on the higher end of the scale, copper systems having a resistivity of approximately 1.68 micro-ohm-cm perform the best, while copper-clad systems display slightly more resistance due to the steel core. Both systems comply with the safety standards, but due to surge currents, the pure copper systems usually have the upper hand when protecting systems in places with heavy thunderstorm activities since they withstand more surges with less resistance. On the other hand, copper-clad systems have pieces that serve functionality and cost, which makes them preferable for installation in homes and offices.

In any case, personal exposure to the environment and the budget will be the deciding factors for these devices.

Advantages of using copper instead of steel and aluminum conductors

It is common knowledge that copper conductors drastically outperform any alternatives because of their conductivity – around 60% more than aluminum. This remarkable level of electrical performance means that copper conductors can be relied on to transmit energy without losing much, which is the ideal characteristic for multiple devices. Copper’s capabilities also set it apart from aluminum or iron since its high tensile strength enables it to endure great mechanical stress and harsh conditions without breakage or deformation.

Another advantage is that copper offers above-average thermal resistance, increasing its suitability for handling higher current loads without overheating. This makes copper especially suitable for demanding infrastructures like high-rise buildings, industrial facilities, and power distribution systems. Additionally, copper’s resistance to corrosion allows for low maintenance and long-term durability even in harsh environmental conditions such as coastal or industrial regions subject to moisture, chemicals, and other aggressive elements.

From the point of installation, copper’s ductility and malleability withstanding allow ease of handling during wiring or configuration, resulting in faster installation processes. Although copper may be pricier than aluminum or steel initially, its longer lifespan, decreased energy losses, and diminished maintenance expenses render it more cost-effective in the long run.

What Equipment Do You Need for a Complete Lightning Protection System?

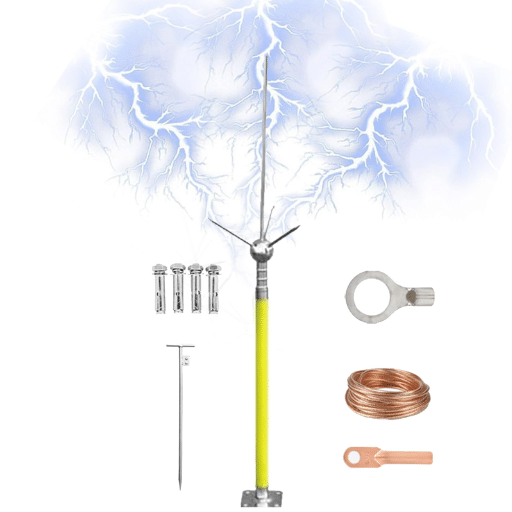

Key parts of a copper lightning protection rod kit

A lightning rod is a copper rod placed on structures to attract lightning and direct it to the ground, preventing damage to the structure.

Air Terminals are sharp rods fitted on top of structures to attract lightning near the vicinity of the structure.

Copper Conductors are high-quality copper wires that link the air terminals to the lightning rod’s grounding system for safe energy transmission.

Grounding Systems are rods or copper plates placed underground that protect the lightning rod from intense electric shock by safely channeling the electrical energy into the earth.

Easy Connectors and Fasteners are strong parts of the system that secure or join parts together, maintaining optimum stability and minimum movement of the whole system.

These components provide a reliable building block for proper lightning attack protection systems.

Attention to Details for Air Terminals and Conductor Cables Selection

Air Terminals and Cable Conductors are generally recommended to be of outstanding quality and commensurate with recognized safety standards such as UL and IEC certification. Wires used for conductor cables are most likely made of copper or aluminum because of their high conductivity and strength. They must also be the correct dimensions for the estimated electrical load to be safely used with the cable.

For air terminals, select models constructed of stainless steel or aluminum due to their corrosion resistance. These materials can endure harsh weather conditions. The height and placement of air terminals should conform to the building design, coverage requirements, and modeling needs so that protective measures are maximally effective. It is best to consult a professional for design compliance with pertinent codes and to maximize system efficiency.

Specification of UL-Listed Lightning Protection Equipment

Lightning protection devices that are UL-listed are ensured to be safe and to perform reliably, as they have met stringent safety and performance requirements. Consider the following specifications:

Air Terminals: Able to withstand extreme weather conditions, such as corrosion, the building, and maintenance of these devices should begin with copper or aluminum alloy materials, as they are known to serve the durable purpose they intend to, enduring over time. Also, they should be sized appropriately for the application.

Conductors: The most common materials for conductors are heavy gauge copper or aluminum, as they tend to provide low electrical resistance while efficiently directing lightning currents to the ground.

Grounding Systems: They should also construct Shielded ground rods or plates that ensure proper sizing and effective lightning energy disposal into the surrounding earth.

Fittings and fasteners: Require judicial restraints to maintain secure bolts, chains, or straps over time and ward off weathering.

Ensure that the safety specifications are honored with the equipment certification marks UL. However, it is essential to seek the manufacturer’s installation and maintenance construction guides that provide safety and an optimized system functionality consulting code.

How do you install a copper lightning rod on different roof types?

Bolt-on System for Houses, Bungalows, and Tin House owners

Copper lightning rods require careful consideration for their installations on the different roof types, which are often overly careful about specific structures and materials.

House Roofs: The construction of the house gives unique features such as warmth – serves as the primary influencer in the step-by-step process of putting up their lightning rods. The first involves attaching the rod to the peak or the ridge for maximum lightning coverage. These are usually aided by brackets or clamps, which also ensure that the roof is not dented and demolished due to the strokes of the rod. Moreover, recommended and good practice has shown that at least nonferrous metals should be used in regions of high snowfall or humid areas for fasteners to avoid structural damage.

Bungalows: Unlike the traditional French Bungalows with a Frozen slant or level off a roof. This type of Bungalow does require some mild modifications. It is best that you install the lightning rod in mind halfway between the center side and the top of the bulbs. Unlike flat roofs, it is best to strap the rod down in a watertight seal if it gets trapped in one of the edges of the drainage or waters it geisha or length of pyramids, which aids in ensuring that the outer surface of the rod helps.

Tin House Structures: Proper insulation above the lightning rod, especially between the base and the structure, is critical to combat electrical conduction through the roof. Non-conductive mounting bases or pads are frequently employed to insulate the connection point of the screw. Moreover, quality cable ties guarantee that grounding cables are affixed along the roof safely and bonded without damaging the roof’s material and protective coating.

Considering the building’s topography while maintaining safety and ruggedness standards, customizable mounting methods for different roof types can be applied, increasing the efficiency and dependability of lightning protection systems in various architectural designs.

Correct placement of the lightning rods: maintaining the rods as the tallest parts

Rods must be placed at the highest points to ensure lightning rods have reliable performance. Proper rod placement is of utmost importance. Rods for the lightning protection system should be positioned on the structure at its highest features and must always be the first to put on a framework that risks being struck. Lightning conduction must be redirected straight to the building, so mounting bolts on ridge tiles, chimneys, parapets, and even flagpoles that stick out of the building is a good choice. This improves the chances of safely directing the stray current into the ground through the grounding system.

Per industry guidelines, conductor rods’ spacing and height must encompass the “zone of protection” a building possesses, employing a standard 1:1 height-to-radius ratio for coverage in most designs. Moreover, even taller structures may need multiple rods with conductors to shield the area under protection comprehensively. Wind loads, structural material, and overall exposure must be carefully considered to maintain the installation’s effectiveness and durability. With the guidelines intact, correctly placed lightning rods can protect structures from the enormous energy surges of natural electrical discharges, shielding property and lives.

Installing detachable lightning protection equipment for maintenance

Detachable lightning protection equipment is a flexible design solution developed for lightning protection that can be removed without compromising system security. These systems employ modular design principles, allowing parts to be removed or replaced without dismantling the protective system. In doing so, ducting removal enables complete examination of significant components like conductors, grounding systems, and air terminals, allowing maintainers to ensure optimal performance.

When designing detachable lightning protection systems, use corrosion-resistant materials, such as stainless steel or copper alloys, due to their exceptional durability, even under extreme weather conditions. Using clamps and threaded connectors as quick-release features eases access to the system for reattachment and access, minimizing downtime and lowering risks of structural interruptions. Streamlined maintenance is also achieved through the adequate labeling and marking of these components to proper documentation.

Focus on advanced monitoring technologies to make control practices regarding detachable systems more effective. Modern devices and sensors that can be placed on the system aid alarms for possible wear and faults, such as electrical failure or degradation of operative electrodes. By dealing with problems well in advance, the chance of issues with striking lightning is significantly reduced; hence, optimizing safety systems is crucial. Remember, careful planning and modern materials and tools make detachable lightning protection systems a reliable upgrade to old and new buildings.

Step-by-Step Guide to Installing Your Copper Lightning Rod System

Tools and preparations before mounting your lightning rod

Prior to setting up your copper lightning rod system, make sure to complete all the necessary steps for a safe workspace and reliable installation. A copper lightning rod system requires specific tools, which include a glove for safe material handling, drills and drill bits for affixing components, wrenches for bolts and fittings, and tape measuring tools. It also requires marking tools alongside the measuring tape so one can mark precise points of installation.

For integration into an electrical system, you will also require a bonding strap, cable clamps, and a grounding rod so current can safely flow through the system. Confirm the installation guide for needed parts, as modern installations also require special brackets or insulating mounts. The rod also requires copper cables for connection to the grounding system, so ensure you have them beforehand.

Check the roof or mounting area for proper structural stability, as these steps will follow. Remove workspace hindrances, debris, and other obstacles that may interfere with the plumbing or electrical lines, and pre-plan your installation route. Weather conditions must be dry and safe, not allowing work to be done at heights. As a rule, the installation of lightning rods cannot be performed during thunderstorms or rain, which makes planning critical to facilitate streamlined installation at the intended time, as well as during dry weather. Preparation ensures that effective planning is achieved for long-term reliability and prevents undesired system failures.

Securing the air terminals and running conductor wire

Ensure optimal efficiency, reliability, and durability with the lightning rod-like structure in place. Secure the towers, rooftops, and areas with relative height distance using the corrosion-resistant brackets that were previously described, as these will give you the foothold needed to Attach your parts. Ensure that any air that is terminal is adequately positioned and that there are no gaps confined within the ranges left before starting this process to avoid failures from weather extremities and stress. These need to be withstood over time, which is strategically preventing secondary installations later on to guarantee adequate coverage that will provide the building adequate protection against strikes.

Once the air terminals have been attached, the next step is to run the conductor wire to channel lightning currents safely to the ground. Make sure to use heavy-duty wire made of copper or aluminum to ensure high conductivity. The conductor wire should be attached along its path’s length and free of sharp bends, loops, or kinks that hinder safety and conductivity. Wires must maintain a minimal distance from others and do not disturb utilities to avoid damage. Secure grounding by attaching the conductor wire to a suitable grounding electrode system is also important.

This systematic approach guarantees the lightning protection system meets safety standards, performs reliably, and offers comprehensive coverage for long-term structural safety.

Outlining the Proper Grounding of Your Lightning Protection System

Efficient functioning, property protection, and structural integrity under lightning strikes depend on the practical grounding of lightning protection systems. When protecting structures from lightning damage and structural fires, a strong grounding system funnels the electrical energy of a lightning strike into the earth. The National Fire Protection Association (NFPA) emphasizes a specific standard towards grounding, and it is highly recommended to use aluminum or copper due to their durability and conductivity. The electrodes are buried at sufficient depths and spaced out enough to facilitate the harnessing and dispersing of electrical energy by rods, plates, or meshes. The effectiveness and safety of the structure are enhanced when the device’s resistance is kept low, ideally below 10 ohms. Safety inspections and thorough corrosion and wear checks should be done regularly to maintain the efficiency of armor grounds.

What Maintenance Does a Copper Lightning Rod System Require?

Check your lightning protection system after a storm

Each season, my priority after a lightning storm is to check my protection system to see if it has suffered any damage. I always examine the copper lightning rod and whether it is appropriately positioned. Checking whether parts have been bent or harmed due to bad weather is something I have learned that needs to be done.

Immediately, I start with the grounding system, an essential protective framework. I focus on checking corrosion on the connection or ring junction and whether the copper wires are firmly connected and intact. If I see too much damage or corrosion from metal oxidation, then I am sure to take apart those parts to keep the system’s effectiveness and energy movement effects low. Also, I control the juncture between constructing the whole system and the building itself, checking whether all the bolts are tight enough.

Lastly, I look around for any new landscaping and soil erosion issues that may affect the effectiveness of the grounding. If necessary, I get a specialist to do further testing, such as resistance measuring, to see if the system is safe. These checks, done after each storm, allow me to be sure that my lightning protection system is in the best condition and functioning effectively, ready for the upcoming storms.

Removing tarnish and preventing copper components from corroding

Protecting the system from corrosion and keeping the copper parts of the lightning protection system clean is done by inspecting the components for any signs of oxidation or tarnishing. For cleaning, I use distilled water alongside some mild vinegar or lemon juice. The formula is applied using a soft rag or a brush. Scrubbing should be done carefully to avoid damaging the surface of the copper. The residue must be washed with distilled water so that residue can be removed, which would cause corrosion in the future. To reduce corrosion in the long run, I must dry the parts after cleaning to avoid moisture build-up.

I apply dielectric grease or an anti-corrosive spray made for copper to minimize further corrosion. These protective coatings also block water and other pollutants that may cause tarnishing. Moreover, I ensure all the copper connections are secure, as loose fittings can cause galvanic corrosion when coupled with other metals.

Routine maintenance is essential to increasing the effectiveness and longevity of these components. Combining inspections with the appropriate cleaning, protective, and maintenance measures enables me to keep my lightning protection system in optimal working condition to minimize wear on the property while maximizing safety.

When to replace lightning rod parts

Effective lightning rods are a critical component of a lightning protection system, and its parts must be well cared for. All elements must be inspected regularly for signs of corrosion, wear and tear, cracks, bends, or missing pieces. In case a massive thunderstorm occurs or high winds of thunderstorm wind warning levels arise, a thorough assessment must be conducted on the grounding systems, conductors, and the rods themselves to identify potential damage. If any parts are significantly or visibly corroded, they must be replaced immediately to ensure the system can safely dissipate electrical energy. Failure to do so increases the risk of damaging property or creating safety hazards during thunderstorm scenarios.

Frequently Asked Questions (FAQs)

Q: How does a pure copper lightning rod differ from its copper-clad counterpart?

A: The primary difference between copper-clad and pure copper lightning rods is the material used to create them. Copper requires more finances as it is wholly made out of copper, whereas a copper-clad rod has a steel core covered with copper so that electricity can travel through it; however, it is not as efficient. Both rods are beneficial for lightning protection, but pure copper rods are superior in conductivity and longevity, whereas clad items are stronger due to their steel core.

Q: What is the ideal height for a lightning rod atop my bungalow or tin house?

A: A lightning strike rod must extend a minimum of 10 ft above the top of your structure, which applies to a house roof, bungalow, or tin house. According to NFPA guidelines, the rod must extend 10-12 inches above the roof’s highest point. It’s important to remember that lightning strikes tend to hit the top portion of the building, thus preparation gives the structure a 45 degree protective cone. A perfect height lets the house intercept the lightning and shield the building from damage.

Q: How reliable lightning protection systems should I use for the diameter and AWG?

A: To achieve optimal reliability in lightning protection systems, a central lightning rod made of copper or clad copper should have a diameter of no less than 3/8 inch (10mm). The grounding conductors should have a copper cable of no less than AWG 2 (about 6.5 mm in diameter), but it is preferred to use AWG 1/0 (about 8.25 mm) for the main download. AWG 4/0 might be required for larger structures. These specifications ensure the components can safely endure the extreme electrical energy from a lightning strike. Remember that undersized components will likely fail during a strike, so using higher-than-standard components could give reliable protection.

Q: Is there a process for installing several lightning rods on tall structures, such as towers?

A: For tall structures like towers, first find the aerial view’s regions most prone to being struck. Install each lightning rod at a height of 10-12 inches above the structure. Place rods at a 20-25-foot distance to create combined protective coverage zones. All lightning rods should be connected using copper cables AWG 2 or larger, forming a complete network. For towers, place rods along the highest points and install down leads along multiple sides directed to dedicated ground rods. This system helps to divert strikes from damaging the tower structure.

Q: What tools do I need to securely attach a lightning rod to my roof?

A: To properly attach a lightning rod, you need the following tools: mounting brackets that match your roof type (flat, pitched, etc.), stainless steel or brass bolts, nuts, flat washers, and lock washers to keep them tightened, cable fasteners that hold the download cable, waterproofing tools that stop roof leaks, and weatherproof materials. If your rod has a threaded base, you must have the right thread size for your mounting block. Customers often purchase the kit from amazon.com. Use high-quality corrosive-resistant tools for lightning protection systems, especially those built using the most tested materials for best results.

Q: Which is better for coastal region lightning rod hardware, brass or stainless steel?

A: For coastal regions, both contain pros, but brass is better overall for lightning rod hardware. Brass is a good conductive material (which is necessary for lightning protection) and greatly resists corrosion in salt air. While good-quality stainless steel (316 grade) does have some resistant corrosion, it has poor electrical conductivity. Because of the salt water, braces conductivity makes it much better for terminals, connectors, and fasteners in lightning protection systems. They still prefer brass hardware in coastal regions because of its long-term reliability, even though it makes these regions move away from other materials.

Q: How do I verify that my lightning rod system is grounded correctly?

A: The grounding of a lightning rod system is acceptable if it has a resistance of 10 ohms or less when a ground resistance tester is used on the system. Verify that each download is connected to ground rods extending 10 feet into the soil or water table. Ground rods must also be at least 10 feet apart and bonded to ensure proper spacing. Additionally, the system must be bonded to the electrical ground of the house and other metallic components. If there is damage caused by lightning burns or damage to your property despite having a rod installed, it can be assumed that the grounding is insufficient. Thorough testing is ideal at least once a year, ideally after significant weather changes or events, to check how well-installed systems withstand the test.

Q: Do lightning rods attract lightning, or do they simply divert it over safely?

A: As is commonly believed, lightning rods do not attract lightning bolts from afar. They merely divert lightning to a route where it would have struck naturally. Lightning energy will always take the path with the least resistance to ground, and an adequately installed rod system provides that. The rod intercepts the strike and safely conducts the enormous electrical energy through heavy gauge wire to the ground, protecting your structure. Some customers have the notion that adding a rod increases the chances of the strike, but scientific evidence proves otherwise. Lightning protection systems do not increase the chances of a strike; they merely enhance safety whenever a strike happens.