Selecting the appropriate bus tire for your commercial vehicle is a decision that will affect its performance, safety, and cost efficiency. With the vast selection available in the market today, trying to narrow it down can feel very overwhelming. The right choice must be made regarding tires because it can make or break operations, considering factors such as tread design, tire durability, weather compatibility, load capacity, and more. This guide aims to empower fleet managers and business owners by providing them with the key terms they need to keep their fleets running efficiently and safely. No matter what your role is, there are decisive factors that every fleet manager should consider to avert overwhelming details that can cloud your judgment.

What Are the Key Factors in Selecting a Bus Tire?

Understanding Tire Basics for Buses

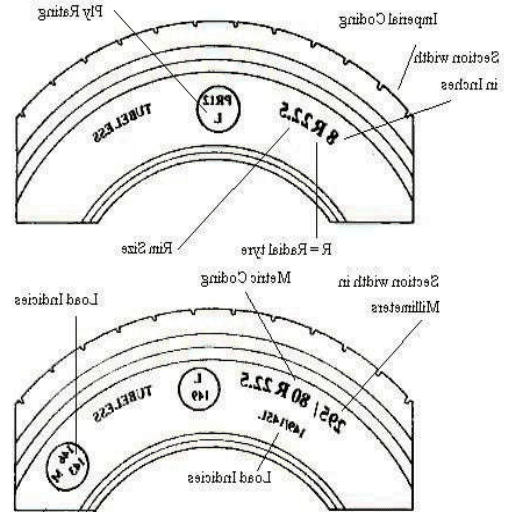

When choosing bus tires, it’s essential to consider their constituent parts and how they affect performance. These components differ significantly and include sidewalls, treads, and specialized compounds that enable the bus tire to endure significant amounts of stress and frequent stopping. Heavy stopping and consistently halting the bus put a lot of strain on the bus console, and these parts are critical, considering factors such as sidewalls, size, ply rating, tread design, and load-carrying capacity.

Sidewalls, size, ply rating, tread design, and load-carrying capacity are integral parts of the tire over the range of stresses that include compressive, tensile, and torsional stresses. Along with this, these factors also ensure compatibility with the manufacturer’s specifications, which maintain safety. Not maintaining precision with any of these factors, especially diameter, translates to a significant decrease in performance and a substantial increase in danger.

Guided by these basics, you can make smarter fleet choices while taking full advantage of the evolving innovations in tire technology, which include reduced environmental impact, low-rolling resistance compounds, and improved fuel efficiency.

Significance of Load Bearing Capacity in Bus Tires

Bus tire selection heavily relies on load-bearing capacity as it impacts the overall safety, performance, and operational efficiency. While bus tires are designed to withstand considerable weight from passengers, baggage, and the vehicle itself, there is a danger in exceeding these limits. Overexcessive weight per tire results in decreased performance, including traction, wear, and leverage beyond set boundaries, as well as increased safety risks such as blowouts.

Bus tires are constructed using advanced technologies that enable them to endure high amounts of stress while remaining stable and mitigating loaded sidewalls to prevent over-stressing on tendons. A standard city bus equipped with tires of larger diameter and paw prints has a volume index value and can carry over 8000 lbs per tire. Alongside meeting load-bearing limits allocated for certain axles, operators need to pay attention to stowage and ensure its middle is bottomed out to avoid stressing certain tires.

Furthermore, when buses fall within defined limits, fuel and compound spending are optimized, and tire lifespan is extended. Alleviating specific components of stress when providing their recommended bounds makes them operate smoothly, reducing overall spending costs. As best practice, operators should ensure the correct pressure is supplied to the tire before use to maximize results with minimal effort, as reduced inflation directly affects the results.

Assessing Durability and Tread Designs

For heavy-duty and commercial use, durability and tread patterns significantly impact the tire’s efficiency and lifespan. An effective tire must be able to endure extreme stresses, both environmentally and mechanically, including high temperatures, rough landscapes, and heavy weighting, without losing its core functionality. Advanced Engineering modern tires, made with high-quality materials and sheer-sided walls, get the job done by resisting wear and tear over time.

Given that a tire’s capability to optimize on both traction and stability is a function of tread patterns, they are no less important. For example, off-road and muddy environments require deep, aggressive tread designs because they provide greater grip and better stone-ejecting capabilities. The highway requires smoother, more symmetrical patterns that enhance fuel efficiency, decrease noise pollution, and provide better road traction. It is also important to ensure that tread patterns are paired with the respective operating environment to optimize tread life and safety, especially on wet or uneven surfaces.

Furthermore, technological advancements like multi-layer treads and wear-indicating marks enable operators to track tire wear and performance more accurately. These features help operators maintain equipment with fewer work stoppages and eliminate dangers associated with unexpected tire failure. Considering durability and tread design allows operators to achieve satisfaction corresponding to their performance and operational requirements.

How Does Tire Size Affect Performance?

Choosing The Right Tire Size For Your Bus

Like any vehicle, the performance (including safety and fuel efficiency) of a bus is also highly determined by its tire size, so choosing the right size is very important. The size of its tires directly influences a bus’s handling, stability, and load-carrying capacity. For example, larger tires are more efficient for long-distance routes or uneven terrain, as they provide increased stability. Smaller tires, on the other hand, are better suited for urban environments with frequent stopping and turning.

In addition to considering the tire size, it’s also essential to consider the GVWR, passenger capacity, and operational conditions. Moreover, broader or larger tires are shown to be more effective due to their ability to distribute weight more efficiently, which reduces stress on individual tires and thus extends their lifespan. Also, abiding by the manufacturer’s instructions is very important, as most vehicles are built to function optimally with specific tire measurements.

Alongside these factors, manufacturers recommend their own tire sizes, which, if ignored, can jeopardize a vehicle’s operational safety. Notably, safety standards are affected by industry discrepancies of recommended sizes, which result in increased braking distance and decreased steering response. Careful consideration of the factors outlined above can help operators greatly optimize performance.

Effect of Tire Size on Fuel Economy

The dimensions of a vehicle’s tires impact fuel efficiency in terms of rolling resistance, weight, and aerodynamics. Driving at higher speeds, larger tires tend to have more rolling resistance because they are in greater contact with the road surface, increasing fuel consumption. At slower speeds, fuel is burned at significantly lower levels due to the lower power requirements of smaller tires. At higher speeds, smaller tires do tend to lower rolling resistance, however, grip and handling tend to suffer especially when load and weather conditions turn hostile.

Newer studies in the automotive industry show that a 10% increase in rolling resistance correlates with a 1-2% increase in fuel consumption. Likewise, the width of the tire is a factor in aerodynamic drag—wider tires will create more friction and turbulence on and around the vehicle, which could lower fuel economy over time. Hence, to optimize fuel efficiency, manufacturers recommend tire dimensions that contribute to performance, mileage, and conservation. Operators are also encouraged to check the tire’s inflation level, as flat tires, regardless of their size, increase rolling resistance and fuel expenditure. Careful management of these components allows drivers to reduce fuel costs while ensuring vehicle operation is not impeded.

Why you should care about load index and speed rating

Both the load index and speed rating are two of the most critical indicators that give you detailed insight into what a tire can do. The load index indicates the maximum weight a tire can bear when inflated. For example, an average load index of 91 means the tire can carry a load of 1,356 pounds. Comprising higher values implies the rest of the tires are intended for heavier vehicles. Evaluating this metric means the driver has a higher potential for safety, as they can choose the appropriate tire without exceeding their vehicle’s weight limit.

Like that, the speed rating shows how fast a tire can be driven on while still maintaining the structural integrity of the tire. A tire’s design also influences the letters (S for 112 mph and H for 130 mph) it chooses. Today, cars often use tires that feature speed ratings correlated to their intended function, meaning higher-tier cars need more advanced tires. Sourcing both the load index and speed rating, drivers can purchase the optimal tire to ensure safety, durability, and efficiency based on their driving needs.

How Can Proper Tire Care Extend Tire Life?

Key Guidelines for Bus Tire Care

Consistently Check Tire Pressure – confirm that it is set according to the manufacturer’s guidelines. Tires at incorrect pressure levels may inflate and deflate unevenly, increase fuel consumption, and pose safety concerns.

Perform Regular Checks – look for visible damage, such as cuts, cracks, or any external materials stuck inside the tire, as these can affect safety and reliability.

Check Your Wheel Alignment – Unaligned wheels shift vertically and horizontally relative to the tires, leading to more intense wear on specific tire sides and further damage due to increased friction. Schedule and pass regular alignment checks.

Regularly Change the Tire from One Position to Another – it keeps the tire from getting damaged as it wears out at a consistent rate, while maintaining constant performance.

Ensure the Correct Maximum Capacity – don’t overload the bus, as it can damage the tire beyond repair and lead to other troublesome issues.

Following these guidelines allows the bus to operate safely, use significantly less fuel, and have strategically set their budgets.

The Consequences of Neglecting Tire Inflation Checks

Keeping tires properly inflated directly impacts bus safety, efficiency, and the longevity of bus tires. Safety-wise, underinflated tires create additional friction, making them more likely to overheat during travel, especially on long-distance journeys. Pitfalls stemming from over-inflation are equally concerning. Detracting significantly from grip, overinflated tires cause only the edges of the tires to contact the road. The result? Reduced responsiveness and increased risk while braking.

Driving is not the only aspect negatively impacted by improper inflation. Fuel consumption also takes a significant hit. Properly inflated tires can help you achieve a 0.6% boost in fuel efficiency. This remarkable number can surpass 3% in certain situations. These inequalities do not just burden the bus system. Controlling emissions and protecting the environment are other drivers of changing fuel consumption tendencies. In addition, uneven tread wear can be prevented with properly maintained inflation levels. In essence, proper tire maintenance helps prolong the replacement cycle significantly, easing the financial burden. To reap the maximum benefits, use a reliable gauge to check tire pressure every week, considering the manufacturer’s recommended PSI levels. Eliminating bus inflation constraints supports economic and ecological efforts.

Signs of Wear and When to Replace Your Tires

Being able to notice the signs of tire wear early is crucial for maintaining vehicle safety and performance. One of the most noticeable signs is the default tread height. Treads should not be lower than 2/32 of an inch; many safety specialists recommend replacing them earlier, especially in moist or snowy conditions. Drivers can easily check the tread depth by using a penny or a tread depth gauge. Another indicator is uneven tread wear, most commonly associated with misaligned wheels or improper tire inflation. Check your tires regularly for bald spots or irregular, excessive wear on one side.

Cracks or bulges in the tire sidewalls are an equally alarming factor. These abnormalities may suggest structural damage or cause the tire to fail, posing a danger. Furthermore, tires need to be checked for various objects, such as nails, needles, or glass. While these objects do not cause immediate pressure loss, they can cause a gradual pressure depletion in the tire or an explosive failure. This is another component to keep an eye on. The average user spends more than $700 on maintenance due to age. Most users do not need to replace tires due to wear from daily activities for 6-10 years, as rubber starts to lose its durability. Noticing these guarantees, safe expenditures increase fuel efficiency and prolong the vehicle’s lifespan.

What Role Does Rolling Resistance Play in Fuel Consumption?

Learn about Rolling Resistance and Its Impact

Rolling resistance means the energy wasted when a vehicle moves its wheels. This force comes from the tire’s contact with the road, its deformation, and friction in the tire. Rolling resistance has a significant impact on fuel consumption. Higher rolling resistance means greater fuel consumption because it makes the engine work harder, while lower rolling resistance allows the engine to operate more efficiently.

Rolling resistance is mainly determined by the tire design. The resistance can change with the material, tread design, and tire pressure. For example, when a tire is under-inflated, it has more contact with the road, which leads to greater deformation and greater rolling resistance. Research suggests that using low-rolling resistance tires can reduce fuel use by 3 to 5 percent, which is beneficial for budget-conscious drivers and sustainability.

Along with everything else, the type of road surface impacts rolling resistance. Roads that are smooth and well-maintained have less rolling resistance in comparison to rough ground surfaces. Using tires with the correct pressure, that are offset for straight driving conditions, and of the right type greatly increases the vehicle’s performance and efficiency in fuel consumption. By controlling and understanding rolling resistance, you can manage and make choices that are both economically and ecologically friendly.

Choosing Tires with Optimal Rolling Resistance

Choosing the correct tires has the most significant impact on rolling resistance, which in turn affects the fuel efficiency and performance of a vehicle. Modern low-rolling resistance tires are designed using sophisticated rubber materials and tread patterns that minimize energy loss while ensuring good traction and durability. These specialized tires can reduce fuel consumption by up to 10% compared to standard tires due to advancements in tire engineering.

When selecting tires, other factors such as load capacity, driving conditions, and tread pattern should also be considered. “Low rolling resistance tires” is a classification given to tires that are made with better, more flexible silica-rich compounds that are less prone to generating heat. Also significant is proper tire inflation, as underinflation significantly increases rolling resistance, which leads to increased fuel consumption and wear.

There is also the consideration of the balance between rolling resistance and wet grip braking performance, as well as how reliable these attributes are as safety features. Using these strategies will go a long way toward achieving significant cost savings and reducing emissions to protect the environment.

Boosting Fuel Saving Using Tires

It’s no surprise that selecting tires wisely can significantly boost fuel economy. There are tires specifically made to achieve lower rolling resistance. Such tires, also referred to as low-rolling resistance tires, allow a car to drive with less energy, meaning it will consume less fuel to achieve the desired speed. This means that low-rolling-resistance tires can boost fuel efficiency by 3–4%, which translates to significant savings over time for drivers.

The materials used for the tire and the tread design are crucial. Advanced materials such as silica compounds not only offer better grip, but they also add lower rolling resistance in the equation. Moreover, better energy transfer and less heat buildup result from optimally designed treads, all of which improve fuel economy. A reduction in CO₂ emissions of almost 10g/km is reported through industry studies when tires are properly designed and not over-engineered.

Other than that, regular maintenance goes a long way in ensuring riders get consistent fuel economy. Drivers should check tread depth alongside alignment for the best results with balanced tires and regular rotations. Effective height maintenance, combined with novel tire technology, gives individuals the ability to reduce fuel consumption while using environmentally friendly methods significantly.

How to Optimize Your Tire Selection for Long-Distance Travel?

Long Haul Buses: Understanding Their Specialized Requirements

In the case of long-haul buses, their unique needs focus on their operational efficiency, safety, and overall robustness. The first and key focus when it comes to long-distance travel is selecting the correct set of tires, and in this case, the proper set is one that specially caters to long-distance travel. Economically feasible routes require strategizing to ensure optimum fuel efficiency, which involves using tires with low rolling resistance. Another critical fuel requirement is endurance, because the long-haul buses’ tires will easily deteriorate over thousands of miles. Tire performance features, such as reinforced sidewalls coupled with modern tread designs, ensure constant reliability during mid-use while maintaining a good level of performance on all road types.

Aside from comfort, which is another primary focus, smooth and quiet bus interiors, free from vibrations and noise, are other expectations from passengers. On longer trips, long-haul buses need to consider shock-absorbing and noise-canceling tread patterns, which significantly improve passenger comfort during travel. Still, dependable passenger safety requires adequate handling and braking under changing road or weather conditions. To cater to these needs, proper grip and optimal stability provided by good-quality tires will go a long way.

Lastly, I examine sustainability and cost-effectiveness in the longer timeline. Retreadable tires, for instance, enable buses to minimize expenses and waste while maintaining the tire’s value with proper care. Subsidizing premium tires incorporates advanced technologies like eco-friendly elements, ensuring my fleet is operated efficiently while minimizing its impact on nature. With careful consideration of tire choices and regular scheduled maintenance, I can efficiently operate long-haul buses to provide dependable service to travelers while maintaining operational excellence.

Selecting Tires for City and Highway Driving

While selecting tires for city driving versus highway driving, I tailor my approach to focus on the unique requirements of each region for safety and performance. For urban driving, I select tires specifically designed for stopping and starting at slower speeds. I also take into consideration the noise level. In city environments, urban tires also feature strong sidewalls.

Tires for highway driving, in contrast, need to deliver performance and comfort at higher speeds while also providing stamina, low rolling resistance, and high fuel economy on urban city roads. For sustained highway cruising, I select comfort-oriented (quiet) tires which do not adversely amplify cabin noise and vibration while offering better fuel economy due to optimized tread patterns designed to maintain traction and minimize wear.

Knowing the differences and requirements for city driving versus highway riding helps me choose the most appropriate tires, which guarantee optimal safety and efficiency while ensuring they last the entire duration they’re meant to serve. These factors help guarantee that, regardless of whether my fleet is operating in city centers or over long, extensive highway stretches, it delivers reliable performance on every trip.

Advice for Maintaining Optimal Traction with Minimal Driving Effort

With everything considered, the foremost action I take is to ensure my vehicles and fleets are fully optimized with regards to traction and grip, which I achieve through the tires’ regular servicing and inspections. The initial step is to meet the tire pressure consistently, as incorrect inflation levels lead to poor grip and contact with the road surface. Over-inflated tires will lose their grip on the road, while deflated tires will result in uneven wear and reduce overall handling. And, of course, following the recommended tire pressure will ensure sufficient grip and contact with the road, guaranteeing stability and overall safety.

An additional practice I follow is checking the tire tread depth. Worn treads reduce a tire’s operability, particularly its ability to maintain grip in wet or slick environments. I make it a point to check the depth using a tread depth gauge and also perform tests like the penny test. I replace the tires when the tread reaches the minimum allowable limits to ensure traction isn’t compromised.

Also, I monitor the weather and adjust my driving style as needed. For example, during winter or rainy seasons when there is snow, I switch to winter tires or all-season tires depending on the region’s likelihood of snow. These steps taken together allow me vehicle traction and grip while making sure it’s safer and more comfortable to drive.

Frequently Asked Questions (FAQs)

Q: What factors should I pay attention to when choosing the right truck and bus tires for my fleet?

A: To select the specific truck and bus tires that best suit your fleet, pay attention to the vehicle type for fleet use, its mileage requirements, how much weight it needs to carry, and the terrain it will be operating on. Also, be sure to select commercial tires that can withstand wear and tear while still performing well in harsh conditions, especially when hauling heavy loads.

Q: How do commercial fleets benefit from using retread tires?

A: Commercial truck fleets benefit from retread tires as they are cost-efficient. Retreading extends the lifespan of the casing while maintaining the performance of new tires. The sustainable qualities of retreads can help lower overall tire expenses while curtailing waste.

Q: Why is selecting the correct sidewall design for truck and bus tires necessary?

A: As with all vehicle tires, the sidewall design for truck and bus tires determines a tire’s robustness. Changes to performance traits, such as durability, resistance to debris, and toughness, rely on the design choices made. Adequate sidewalls can mitigate blowout damage and improve a tire’s ability to maneuver when heavily loaded.

Q: What is the impact of a bus or coach tire’s performance on the installation of the tire?

For bus and coach tires, proper mounting is crucial. Improper fitting can result in uneven tread wear, increased fuel consumption, and even other mechanical failures. Optimal performance can only be achieved by properly installing the tire according to the manufacturer’s specifications.

Q: What is the determining factor of the correct ply rating of the bus and truck tires?

A: For the case of truck and bus tires, the correct ply rating depends on the axle load of the particular vehicle and its payload. The stronger, more durable plies are preferred due to increased demand and heavier loads.

Q: Are there off-road trailer-specific tires?

A: Yes, There is. These trailer tires, designed for off-road use, feature specially reinforced tires that can handle harsh off-road conditions. These off-road tires are designed to provide greater strength and durability for vehicles that work in rough terrains.

Q: What intervals of mileage do commercial truck tire manufacturers provide in their warranties for a truck’s warranty?

A: When purchasing commercial truck tires, a warranty seal ensures certain guarantees regarding their lifespan, as well as performance guarantees against manufacturing defects. Ensure that you carefully analyze the terms of the warranty, along with guarantees on relevant mileage.

Q: What steps should I take to increase the lifespan of light truck tires?

A: The answer to the previous question automatically follows – keep the tires properly balanced, correctly aligned, regularly rotated, and ensure they are not flat. Also, do not overload the vehicle. Routinely inspect the truck tires for damage and ensure tire rotation is done at regular intervals.