Evaluating surface quality and characteristics often makes use of gloss. In manufacturing, design, or quality control, knowing the gloss level of a material sheds light on its finishing work, texture, and visual effect. Gloss meters—tools invented for measuring surface gloss—come into action at this stage. In this ultimate guide, we will walk you through everything you need to know about gloss meters—from how they function to their application in every field. By the end of this article, you will see the importance of gloss measurement, the details of choosing a gloss meter tailored to your requirements, and how these devices assist in achieving uniformity and precision in quality workmanship. Let’s shine a light on the enthralling world of gloss meters!

What is a Gloss Meter and How Does It Work?

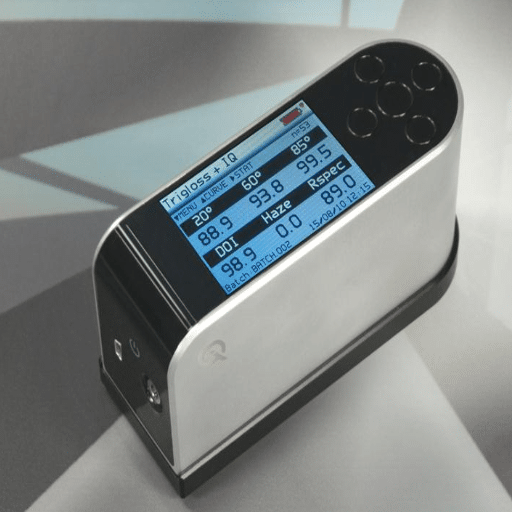

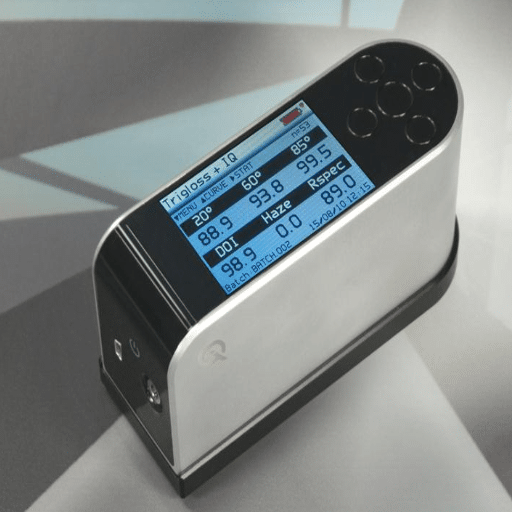

A gloss meter can measure the shininess of a surface, such as a car’s hood. It shows the gloss level as a number. The gloss level can then be determined by analyzing the surface, counting how much light gets reflected, measuring the angle projected, and shining a light at a specific angle. A variation from the expected value results in the surface finish being unacceptable. It is instrumental in the car and paint industry in maintaining the standard of uniformity in products.

Understanding Gloss Measurement

Gloss measurement is essential for evaluating surface quality and appearance in all industries. Measuring gloss indicates how light interacts with a surface, which is necessary for determining the surface’s aesthetic, durability, and functionality. Smooth reflective surfaces will have high gloss values, while matte surfaces will have lower values. Consistent and accurate gloss measurement enhances quality control, product consistency, and compliance with industry benchmarks. Gloss meters and measurement angles of 20°, 60°, and 85° are crucial in attaining reliable outcomes to ensure products are uniformly finished across production runs.

The Role of Specular Reflectance in Gloss Measurement

Measuring gloss relies heavily on surface specular reflectance, which measures the amount of light reflected off the surface at a specified angle. In the automotive, electronics, and packaging industries, reflectance is of paramount concern as the glossed surfaces of these products immediately affect the consumer’s impression of the product. A gloss meter is commonly used to assess reflectance, measuring the ratio of the light reflected to the intensity of light incident on the surface and reporting values in gloss units (GU) on a predetermined scale.

Studies have shown that measuring angle has a substantial impact on gloss assessment. For example, high-gloss surfaces are usually measured at 20° to capture slight differences, and high angles of about 60° are standard for mid-range gloss measurement. On the other hand, low-gloss surfaces are typically measured from an 85° angle to increase sensitivity for discerning slight changes. Industry studies suggest that standards for precise automotive coatings become critical because any deviation exceeding 5 GU can become detrimental.

Modern strategies incorporate specular reflectance data with surface topography data, providing a deeper understanding of the microstructural factors influencing gloss. Such integrations have proven helpful in making manufacturing processes visually uniform and meeting rigid compliance regulations. With precise gloss measurement protocols, industries can sustain quality standards and customer satisfaction in functionality and appearance.

Applications of Glossmeters in Different Industries

Glossmeters have applications in many industries requiring the utmost surface quality and appearance. Let’s explore some major industries and how gloss measurement influences their operations:

1. Automotive Sector

The need for aesthetic appeal and uniformity accentuates the automotive sector’s reliance on gloss meters. These devices determine whether vehicle parts’ painting and polishing processes, especially externally visible surfaces, are done seamlessly. For example, various gloss levels are controlled to produce the reflective coat of the exterior surfaces of luxury cars. The uniform gloss reinforces the enhanced aesthetic appeal of the product and conveys the perception of quality.

2. Printing and Packaging

Glossmeters are heavily utilized in the printing and packaging industries because the surface finish directly affects product marketing and perception. For instance, many high-rated products use glossy finishes for their packages to build a perception of elegance and superior quality. In the meantime, proper gloss is critical in producing high-quality images and sharp text in the printing business. Studies show that glossy-finished packages are more likely to grab consumers’ attention, increasing selling opportunities.

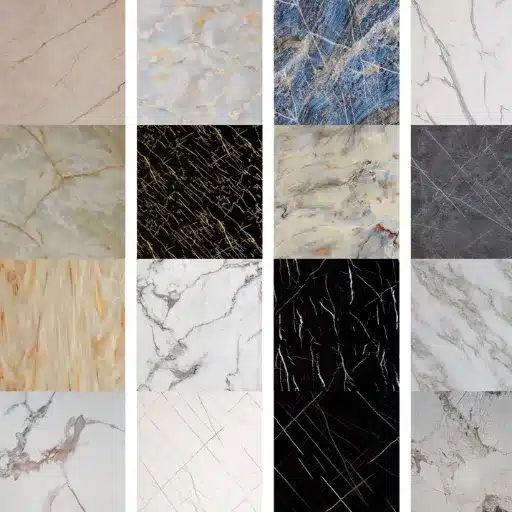

3. Furniture and Woodworking

Furniture manufacturers use glossmeters to measure the sheen level of wood finishes and coatings. They strive to accomplish uniform gloss to satisfy design requirements, whether modernist furniture pieces need high gloss or traditional ones require subdued finishes. Research has shown that high-gloss surfaces on furniture are becoming increasingly popular with contemporary design because of their sleek and attractive appeal.

4. Electronics and Mobile Devices

Like any other reputable business, mobile devices and electronics manufacturers need precise gloss measurements on product displays, casings, and touchscreens. Uniform gloss on the device’s surface beautifies the gadget and boosts its professional appearance. There is a high demand for glossmeters in the mass production of mobile phones and tablets because uniform gloss everywhere, even on the tiny details, significantly influences the user experience.

5. Construction Materials

Construction materials, like flooring and wall panels, use glossmeters to assess the finish of construction pieces. For instance, polished tiles must possess a gloss level free from inconsistencies that disrupt harmony within a space. Moreover, gloss measurement is essential for manufacturing paints and coatings designed for architectural use to ensure a dull surface reflectivity devoid of random rough spots.

6. Cosmetics and Personal Care Products

The reflective surfaces of cosmetic items such as lipsticks, gums, skincare containers, and compact cases greatly influence perceived quality. Glossmeters check that every surface is internally flawless and agate polished to brand imaging perfection. In addition, measurements for polish consistency and gloss in other products like nail polishes are also done.

With pinpoint gloss meters, these manufacturers can now balance visual aspects, functionality, and even customer expectations while standing up to the competition. Meeting regulatory standards has never been easier in these crowded markets.

How to Choose the Right 60° Gloss Meter for Your Needs?

When selecting which 60° gloss meter to purchase, pay attention to the following considerations:

Measurement Scope and Precision: Verify that the device’s gloss measurement range matches your application and meets the required accuracy and reliability.

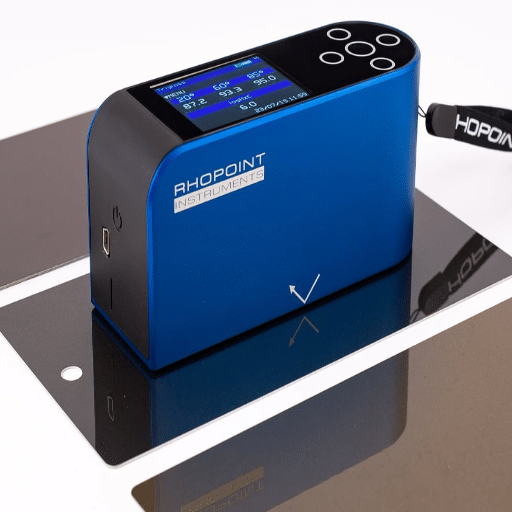

Portability: If regular measurements in multiple locations are required, ensure that the device you choose is lightweight and easy to operate.

Data Storage: Select a gloss meter with internal memory and external device connectivity for easy data assessment and efficient analysis.

Compliance with Standards: To maintain uniformity and quality in the measurements, you should ensure that the gloss meter complies with other industry standards.

Self-Sufficiency and Warranty: Invest in a durable device with a long warranty period to ensure its long-term performance.

These guidelines allow you to select the relevant gloss meter for your needs and tasks.

Comparing Single Angle and Three Angle Gloss Meters

A single-angle gloss meter will be functional for measuring gloss on very flat, simple surfaces, especially if the measurement is taken at 60°. However, a three-angle gloss meter is better for evaluating more complex surfaces and those with a wide range of finishes, enabling measuring gloss at 20°, 60°, and 85°. My selection ultimately depends on how complex my measurement needs are and the precision needed for the task.

Importance of Calibration in Gloss Meters

Using gloss meters entails measuring surfaces and checking their sheen levels, so calibration is key for reliable accuracy. Anyone calibrating gloss meters will ensure proper calibration for level readings with certified checks. Calibration aids manufacturers often provide tiles with known gloss units, 20GU for low-gloss surfaces and 85GU for high-gloss ones.

Proper acceptable furniture manufacturing standards must be observed to maintain tight gloss tolerances. Experts recommend that gloss meters be calibrated every day or before critical measurements. This ensures low bias and high precision. Progressively modern gloss meters are adding features such as automatic calibration alerts and strong chronological records of data for future reference, increasing the reliability of QC control processes. Emphasis on these guarantees mitigates the compromise of production standards which can be critical for industries like automotive where look, aesthetics and high levels of precision s are paramount and where strict gloss control must also accompany seamless user experience.

Evaluating Measurement Angle Options

For accurate gloss measurements, using a gloss meter requires the measurement angle to be carefully chosen. Gloss meter measurements are usually taken at 20°, 60°, and 85° angles, each serving a particular purpose in surface gloss level measurements. 60° is often termed the “universal standard” measurement and works best with most surfaces. Highly glossed surfaces like automotive paint or mirrors work best with a 20° angle because they are more sensitive and show better detail. Surfaces with low gloss or matte finish work best at 85° angle since subtle changes that would otherwise be very hard to detect are easily detected at this angle.

The newest technology includes dual or multi-angle gloss meters that take simultaneous measurements at different angles, which saves time without losing accuracy. For instance, modern devices measure both 20° and 60°. Existing information from comparative studies indicates surfaces with a gloss value above 70 GU need to be measured at a 20° angle, while surfaces below 10 GU perform best at an 85° angle. These enhancements underscore the accuracy level required for any field, such as paint production or quality control of packaging materials. Regarding data reliability, correct angle selection based on the surface type and gloss level is fundamental for achieving standard and repeatable measurements.

How to Measure Gloss Accurately?

For an accurate gloss measurement, determine the appropriate angle: 20° for high gloss surfaces, 60° for general gloss measurements, and 85° for low gloss finishes. The surface must be clean, dry, and free from any substances interfering with the reading. A gloss meter requires calibration, and the device must be positioned parallel to the surface while taking readings to avoid errors. Stick to one of the ASTM or ISO standards for industry verification and trustworthiness. Calibrate the gloss measurement device periodically to maintain accuracy and consistency in readings.

Steps for Using a Portable Gloss Meter

Preparation: Check if the gloss meter is charged or has new batteries. Also, clean the surface whose gloss will be measured to ensure no dust, grease, or other contaminants may impact the measurement. Check the gloss meter’s calibration using a tile calibration set by the manufacturer.

Calibration: Maintain the gloss meter on a provided calibration tile and synchronize gloss meter settings as per the instructions. This ensures that readings will be accurate and reflect industry expectations.

Measurement: With the surface to be tested, place the gloss meter with its face parallel to the surface. Ensure no rotation or free space between the gloss meter and the surface. Press the device’s measurement button or turn it on according to its specific model.

Recording Results: Observe the gloss reading on the screen. Multiple readings are spread across the surface to be measured, and their mean value is calculated for better assessment.

Data Analysis: Assess the gloss level by comparing these measurements against benchmarks like ASTM or ISO standards.

Maintenance: After use, clean the gloss meter with a soft cloth and store it away from dust and potential damage. Perform regular calibration and service checks as the manufacturer recommends for sustained accuracy.

Understanding Gloss Levels and Gloss Units (GU)

Gloss levels and Gloss Units (GU) are necessary measurements of surface reflection quality. Specific measurement angles, 20°, 60°, and 85°, are used to record gloss levels, and these values provide quantitative information regarding a surface’s reflection. Each angle corresponds with a particular surface type—20 ° is for high-gloss surfaces, 60° is a universal reference angle, and 85° is for low-gloss and matte finishes.

GU is the unit used to articulate the gloss level of any surface, and it is defined as the ratio of light reflected off a surface to the light reflected off a surface standard. To achieve perfect alignment a fully reflective black glass sample is set at 100 GU therefore a perfectly polished sample will be 100 GU. For example, high-gloss finished surfaces will record 70- 100 GU at 60° measurement angle, and matte finishes will be below 10 GU at the same angle.

Multiple industries need these measurements for quality control. For instance, GU checks conformity and consistency with aesthetic or functional shallow objectives for automotive finishes, furniture, and flooring. Particular aspects like surface preparation, application techniques, environmental factors, etc., influence the gloss level; therefore, measurement must be precise. Manufacturers and industry experts benefit from the highly reliable data these newly enhanced inspection tools and software provide.

Best Practices for Measuring Low-Gloss Surfaces

Proper techniques provide the most accurate information for low-gloss surfaces when working with technologically advanced instruments. An equally important component of measurements is the angle chosen. For low-gloss surfaces, an 85° gloss meter is more sensitive and better for differentiating because it emphasizes understanding the minor changes in reflection surfaces, which is critical for surfaces with gloss values below 10 GU.

Surface preparation is just as crucial. The region to be measured must be free of smudges, dust, fingerprints, or oil that could taint the readings. No direct sunlight and standard illuminating conditions also help improve the reliability of results.

With sophisticated software, modern gloss meters can generate visual data, compare surfaces, and perform overlaid surface analysis, enabling thorough evaluation with less effort. These devices often come with consistent calibration standards, which help eliminate long-term uncertainty caused by ever-changing environmental conditions.

Repeatable, standardized measurements are vital for the automotive and furniture industries. Controlled production quality demonstrates the need for said measurements. Uniform measuring protocols increase efficiency by reducing gloss adjustment undo work, one-time process, use time, and energy.

Lastly, gloss meters are accurately maintained through routine calibrations. Many devices now feature self-calibrating programs and can certify documents conforming to international regulations such as ISO 2813 or ASTM D523, meeting accepted industry standards and allowing for standardized reporting.

Understanding the Importance of Calibration in Glossmeters

Calibration in glossmeters is essential for ensuring accurate measurements of surface gloss. Without regular calibration, a glossmeter’s readings may drift over time, resulting in unreliable data and quality control problems. Certified calibration standards such as ISO 2813 or ASTM D523 must be used to ensure compliance with industry regulations and maintain precision. This process guarantees maintaining reliable measurement, which aids in supporting the consistency of product quality and enhanced reporting credibility. Simply put, regular glossmeter gloss calibration helps uphold trust in glossmeter readings.

How to Calibrate a Gloss Meter?

The process of gloss meter calibration is singular yet essential to ensure accuracy. Follow these detailed steps to calibrate successfully.

Prepare the Gloss Meter and Calibration Standard: Before calibration, make sure no dust or anything else is on the gloss meter’s surface. Approved standards, like black glass tiles provided by the manufacturer, should be used. These standards must also comply with ISO 2813 and ASTM D523, as these standards are tried and tested.

Check Environmental Conditions: Calibrating should occur in a still setting with no vibrations, cleanliness whisks, or uncontrolled marked humid regions. Ideal calibration should be at normal room temperature, 23°C or 73°F.

Verify the Standard’s Cleanliness: The Gloss’s calibration standard should be debris-free. It must be covered with a lint-proof piece of cloth to guarantee untarnished cloth and Isopropyl alcohol to guarantee thumb marks, grime, or any debris-free cloth. The standard loses its mark and clean value if even minor debris is present.

Align the Gloss Meter Properly: Do not lift the gloss off until the calibration process is complete. The calibration standards need to face the devices. Follow the user instructions to make sure the measurements are correct.

Begin Calibration: Activate the gloss meter’s calibration mode. During this step, calibration should display gloss measurements—and most devices should show the values measured as text—that conform to those provided on the calibration standard. In case some discrepancies arise, the device may need some adjustments.

Adjust if Necessary: Advanced Units often incorporate provisions for digital reconsideration of the gloss value if the readings are wrong. It is advisable to follow the manufacturer’s prescribed method alongside altering the device so that the readings can conform to the standard value.

Confirm and Repeat as Needed: After completing the initial calibration, it is vital to test the measurements by placing the devices on standard items to see if reliable repeat measurements can be obtained. Ideally, the value change upon subsequent measurements should be significant, but not too wide. This is the tolerance band, which is expected to be NO more than the range defined by the manufacturer (in this case, to be declared as ±1 GU).

Record Calibration Data: Logs tracking calibration dates, standards, and results are conducive to proper monitoring, so this log has to be kept active over time with regular intervals defined. These defined intervals can be monthly or before necessary measurements to maintain precision. Some industries will include this as a guiding document to form their compliance constitutions alongside the industry standard that is supposed to be met.

The thorough practices within these steps enable users to uphold the accuracy of their gloss meters while manipulating the manipulators that affect such readings to ensure reliable performance through consistent, accurate readings.

The Role of Calibration Tiles in Maintaining Accuracy

Gloss meters require gloss tiles for accurate performance calibration. Tiles are manufactured to have a specific gloss value, allowing them to serve as a calibration benchmark. Calibration tiles are constructed from glass or polished ceramic because these materials are durable and resistant to wear and environmental degradation over time.

Reviews suggest calibration tiles are carefully cleaned and maintained. Dust, fingerprints, or any foreign material must be removed as they may lead to incorrect readings, necessitating cleaning with a soft, lint-free cloth and non-abrasive detergent. Tiles also need to be periodically checked for gloss value recalibration, as frequent changes, even relatively minor changes, could jeopardize precision gaging in gloss meters.

Measuring gloss without reliable calibration can result in deviations ranging from 10% to 15%, and concerns are raised about whether the standards are met by the automotive, paints, and plastics industries. If those tiles are incorporated into routine calibrations of gloss meters, strict quality thresholds can be achieved.

Understanding International Standards like ISO 2813 and ASTM D523

ISO 2813 and ASTM D523 are two international standards describing procedures for measuring the gloss level of surfaces with a gloss meter. Both incorporate specific measurements for angles known as dihedrals—20°, 60°, and 85°. Each angle represents different levels of gloss and surface types. ISO 2813 is more internationally accepted, while ASTM D523 is primarily used in the United States.

Both standards apply controls to define how calibration and measurements should be made in controlled settings. This set of practices helps the automobile, paint, and plastics industry achieve symmetry when measuring gloss levels, which is very important for product quality. The appropriate gloss angle can be selected depending on a surface’s reflectivity. 60° is the default angle for all-purpose measurements, 20° for highly polished surfaces, and 85° for unpolished surfaces. Accurate global measurements can be made through the union of all these exacting methods.

Exploring the Features of High Precision Gloss Meters

Like any other measuring instrument, gloss meters are manufactured with different accuracy ranges and measuring techniques. Multi-angle measurement—with assessment levels of 20°, 60°, and 85° for different gloss reflection—improves accuracy. They are built with high-resolution sensors to ensure accurate gloss readings even from rough surfaces. Many modern gloss meters also have digital displays with gloss data storage calculators, which make it easy to record and analyze the results. Like other modern gadgets, gloss meters have attractive ergonomic designs with added light weight for convenient on-the-go use in the field and laboratory.

Advantages of Auto Calibration Features

The auto-calibration feature in gloss meters boosts performance while making work easier for users. One benefit is accuracy. With auto-calibration, accuracy alignment is ensured since the device is auto-calibrated to measurement criteria so that gloss assessments can be done with minimal errors and deviations. Studies show that auto-calibrated devices have a significantly reduced margin of error, up to only 1%, versus up to 5% from manually calibrated devices.

Furthermore, auto-calibration also reduces complexity and saves time, which is beneficial in environments with high throughput. Users no longer have to rely on making adjustments or checking calibration frequently, which improves workflows in industrial and lab settings. For example, some modern gloss meters with auto-calibration can recalibrate in less than 5 seconds, allowing them to carry on with work without interruption.

Another benefit is that auto calibration helps reduce maintenance costs and extend equipment lifespan because there is less need for mechanical adjustment, which would otherwise wear components over time.

Finally, automatic calibration helps ensure consistency in data collection. Discrepancies with a single gloss meter may arise with different users because each operator does manual calibration differently. As long as operators perform auto calibration, measurements will be consistent regardless of the operators, thus reproducibility in quality control will be achieved.

How LCD Displays Improve User Experience?

The introduction of LCD (Liquid Crystal Display) technology has improved interfaces in terms of clarity, readability, and efficiency. One of LCDs’ best features is their sharp resolution. Fine details become easily discernible because modern LCD panels have pixel densities exceeding 300 pixels per inch (PPI), ensuring crisp images and less eye strain during long periods of use.

Furthermore, advanced technologies like IPS (‘In Plane Switching’) granted even wider angles. These screens can be viewed from the sides while maintaining correct color brightness, which is helpful in workplaces where several users must simultaneously view the same screen. Alongside the various benefits, LCD screens also use less power, which helps increase the battery life of portable devices like smartphones and laptops. The durability of LCD screens is also something to take into consideration. Most modern panels come with scratch-resistant surfaces and anti-glare coatings, making them easier to use in different lighting environments. As per recent industry statistics, almost 90% of portable electronic devices now feature LCD screens because of their dependability and practical efficiency. This shift accentuates the overwhelming predominance of LCD technology in developing a convenient and effortless interface with users.

The Impact of Measurement Geometry on Results

Measurement geometry is fundamental to obtaining the accuracy and dependability of the data in scientific and industrial applications—the position and orientation of measurement tools about an object or surface under consideration impact measurement results. For instance, in spectrophotometry, the selection of 0°/45° or diffuse/8° geometries significantly impacts the precision of color measurement. Research suggests that 0°/45° geometries give better matte surface measurements, and diffuse/8° geometries are better for glossy or textured finishes.

Also, measurement geometry influences the identification of fine features in obtaining surface roughness parameters. Studies demonstrate that appropriately angled sensors can resolve details of 0.1 micron, which is critical in controlling the quality of mechanically worked parts. The scope of application of 3D geometry is increasing because it allows for measuring complicated surfaces in recording systems in automotive manufacturing and the production of medical instruments.

Benefits in technology today emphasize the attention given to customized geometric arrangements. One specific example is the alteration of angle measurements during inspection, which accounts for robotics movement or irregular shapes, now referred to as AI-integrated dynamic adjustment. Some innovations have boosted the accuracy to 25%, which in automated systems aids in meeting expectations to increase production while minimizing speed or automation errors. All these AI-inspired alterations make it evident how vital precision and measurement geometry are to quality in many domains.

Reference Sources

Studies on Gloss of Printed Surfaces

Development of an Image-Based Gloss Measurement Instrument

A Handheld Image-Based Gloss Meter for Complete Gloss Characterization

Frequently Asked Questions (FAQs)

Q: What is a gloss meter, and how does it work?

A: A gloss meter, also known as a glossmeter or degree gloss meter, is an instrument used to measure the specular gloss or the amount of reflected light from a surface. It uses a specific gloss range and works by projecting light at a specified angle, typically 60°, onto the surface and measuring the intensity of the light reflected at the same angle. This measurement helps determine gloss levels on various surfaces like automotive paint, ceramics, and plastic.

Q: Why is the 60-degree angle commonly used in gloss meters?

A: The 60-degree angle is commonly used in gloss meters because it provides a standard projection angle for measuring gloss across various surfaces. It is versatile enough to measure both low-gloss and high-gloss surfaces effectively. The 60° angle is a midpoint reference that accommodates various surface types in different industries, including the automotive industry.

Q: What is the difference between low gloss and high gloss surfaces?

A: Low-gloss surfaces reflect less light, resulting in a matte or non-shiny appearance, while high-gloss surfaces reflect a higher amount of light, giving them a shiny, mirror-like finish. The perception of gloss is determined by the amount of reflected light, which can be accurately measured using a gloss meter, such as the Elcometer 480.

Q: How do gloss meters measure film thickness?

A: While gloss meters are primarily used for gloss measuring, they do not directly measure film thickness. However, consistent gloss readings can indicate uniform film thickness. Specialized equipment is required for accurate thickness measurement. Gloss meters, like the Elcometer 480, can be part of a broader range of tools used for quality control in coatings and varnish applications.

Q: Can a gloss meter be used on all types of surfaces?

A: Gloss meters can be used on various surfaces, including non-metallic surfaces like ceramics, plastic, and automotive paint. The choice of projection angle, such as 60°, and the gloss range of the meter ensure it can adapt to different surface types and gloss levels to provide accurate measurements.

Q: What is the role of a gloss standard in gloss measurement?

A: A gloss standard provides a baseline or reference for calibrating gloss meters. It ensures that gloss measurements are consistent and comparable across different instruments and applications. Using a gloss standard allows testers to maintain quality control by ensuring that the gloss meter provides accurate and repeatable results.

Q: How does the Elcometer 480 enhance gloss measuring?

A: The Elcometer 480 is a sophisticated gloss meter designed for precise gloss measuring. It offers features like multiple projection angles (including the standard 60°), a wide measuring range, and connectivity options such as a USB cable for data transfer. Its advanced optical system ensures high accuracy and repeatability in various applications, from automotive to ceramics.

Q: What is the significance of using different geometries in gloss measurement?

A: Different geometries in gloss measurement, such as varying the projection angle (e.g., 20°, 60°, 85°), allow the tester to accommodate surfaces with different gloss characteristics. For example, low-gloss surfaces might be better measured with an 85° angle, while high-gloss surfaces might require a 20° angle. This flexibility ensures accurate gloss determination across various materials and finishes.

Q: Can gloss meters be used for automotive paint testing?

A: Yes, gloss meters are widely used in the automotive industry to test the gloss level of automotive paint. They ensure that the paint finish meets the required gloss standards and provides the desired aesthetic appeal. By using a gloss meter, manufacturers can maintain consistent gloss levels in car paint, enhancing the overall quality and appearance of the vehicle.