Ensuring product quality has become an utmost priority in today’s advanced industries, and it is here that the color sort machine comes in. Their unmatched precision has made these machines essential at every quality assurance stage, from food processing and material recycling to whatever niche you can think of. These machines build upon color-sorting technology and are crucial for maintaining industrial efficiency. As industries improve their automation, our expectations of machines have altered. These innovations have powered the development of modern quality control practices. The following article discusses the advantages of color sorter machines to quality control procedures. Read on to understand why these machines are truly groundbreaking.

What is a Color Sorter Machine?

How does a Color Sorter work?

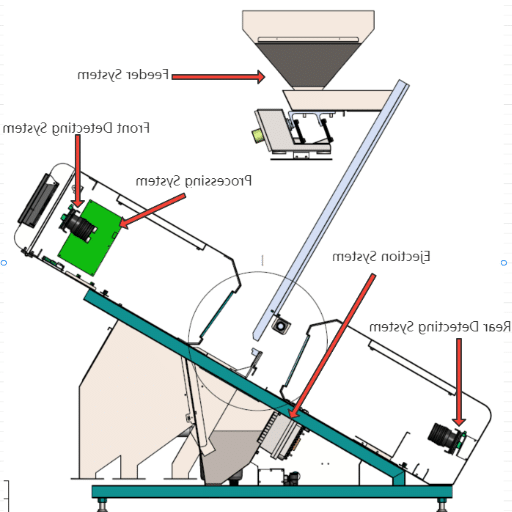

A color sorter machine works through a complex optical detection and precision scanning process. The process starts when raw materials are provided into the machine through a hopper. When the materials move down the chute, high-definition cameras check each material for differences in color, shape, and size. These sensors use high-end technology to detect even the slightest differences in quality.

After the discrepancies have been found, the machine uses a swift air jet or mechanical ejection system to eliminate the unwanted materials from the stream. This system ensures that only desirable materials pass through the machine. Such color sorters can adjust to different types of materials like grains, minerals, and even plastics and can do it with amazing speed and precision. These machines can be programmed to different settings so the operators can modify them according to the requirements in a planned production line, which increases efficiency and precision.

Anatomy of A Color Sorting Machine

Like most machines, a color sorting machine has different components that execute various functions for smooth operations and accuracy. The feeding system is often regarded as the core of the system, as its purpose is to funnel material evenly to prevent jamming. Following this is the Optical detection system, which employs cameras and sensors that detect color, shape, and imperfections in materials!

Illumination is provided by a light source, ensuring the sensors can analyze the materials efficiently. Defective or unwanted items from the stream can be sorted out by the ejection system utilizing mechanical devices, high-speed air jets, or swift air jets. Usually combined with intelligent software, a control system enables users to alter the parameters for sorting orders and review the machine’s performance. Chassis, conveyors, auxiliary hoppers, and parts of the machine’s primary structure provide support and functionality for efficient material flow, which, in conjunction with several other components, makes these machines ideal for many sorting tasks.

What are the types of products that can be sorted?

Modern Sorting Systems can cater to sorting numerous products across many industries. For instance, modern sorting devices automatically segregate plastics, metals, paper, and glass from commingled refuse streams in the recycling industry. The systems can recognize and classify materials based on their composition, size, and even color, which provides high-quality output that can be reused or recycled.

France’s agricultural sector utilizes sorting machines to classify different products, such as fruits, vegetables, grains, and nuts. These machines, equipped with high-tech sensors and cameras, can identify and extract defective products to ensure that only high-quality products reach the market for purchase.

Sorting systems are beneficial in industrial manufacturing, as they can classify pieces or constituents of a product into groups according to specific measurements like size, shape, or materials such as electronic scrap components, food products, and raw materials. Because of technological advancements, the range of products that can be sorted is growing, making these systems essential in modern manufacturing and waste treatment industries.

Why is Color Sorting Important in the Food Industry?

How does Color Sorting Mechanics improve Food Safety?

Color sorting plays a vital role in food safety by separating contaminants and ensuring food product uniformity. Color sorting machines are equipped with high-resolution cameras and optical sensors that swiftly and accurately sort a wide array of unwanted materials like glass, stones, plastic, and even discolored and defective items. These machines help manufacturers reduce contamination risks while protecting consumers from health hazards by separating impurities promptly.

Color sorting also helps improve market appeal by ensuring only high-grade items reach the market. For instance, in processing grains, nuts, fruits, and even vegetables, color sorting can isolate defective pieces for safer appeal. This Intermediary sorting procedure is strict to food industry laws, helping businesses avoid recalls and increasing consumer trust and compliance. This becomes more valuable from a marketing perspective, where color sorting becomes integral to food safety and brand reputation.

What is the significance of color sorting in maintaining good product quality?

We can achieve precision and consistency in sorting with AI and optical technologies. For instance, a modern color sorter in a factory employs high-resolution cameras and sensors to detect blocks of products that do not meet exact standards for size, color, and texture. In the food industry, color sorting machines can quickly remove discolored grains, blemished fruits, or other contaminates such as stones or plastic, which significantly helps in quality control.

Moreover, the reduction of waste is another advantage of color sorting. Industries like agriculture, recycling, and pharmaceutics have become more profitable due to increased precision and output quality. Elimination of borderline products increases resource efficiency and reduces cost. Color sorting increases brand image and builds customer trust by guaranteeing compliance with product requirements. This process is essential for brand value while ensuring consumer safety and satisfaction.

Which Color Defects can be identified using Color Sorters?

In terms of accuracy, color sorters are reliable machinery capable of identifying and sorting various types of color defects. Some common obstructions, as identified, are discoloration, contamination, and variation or inconsistency of colors. For example, in agriculture, color sorters can identify blemished, unripe, and overripe produce and foreign matter, such as soil and stones in grains and nuts. They also involve purposefully stained plastic, mixed polymer scrap, and non-recyclable waste plastic in recycling businesses to enhance the sorting accuracy of color sorters. These systems are also helpful in pharmacies for detecting tablets or capsules with incorrect color coating and those with an abnormal color indicating a defect during production.

The capabilities of color sorters are augmented by the adoption of new technologies like high-resolution cameras and artificial intelligence, which allow the detection of finer degrees of color and patterns that are impossible to see. This reduces wastage because only defective items are removed simultaneously, ensuring maximum throughput. With the recent developments, color sorters can now assist industries with stringent quality targets without suffering production delays or losses.

How Does Automation Enhance the Sorting Process?

What are the advantages of using Optical Sorters?

Every industry has its own unique challenges when it comes to sorting processes, but Optical sorters have been able to improve this for everyone. The first prototype showed how computers could perform sorting much more efficiently, and was later developed to utilize imaging technology for distinguishing colors and shapes along with multiple other parameters. Optical sorters reduce the chances of human mistakes significantly, making it easy to enhance system output with each run.

Another feature worth mentioning is precision, which shows a direct relationship to higher speeds. Manual precision could take years to achieve fine motor skills such as these, while Optical sorters can perform certain actions at a scale of magnitude ranging from 5 to 10 times quicker than a person. This is particularly important in agriculture and recycling, where these technologies can significantly aid biles.

Cost is always essential for a profitable business model, and integrating optical sorters pays for themselves with the reduction in expenses. With fewer hands needed for sorting comes saved labor costs, faster profit from investments, and a move towards greener business practices.

Lastly, optical sorting technology is versatile. Modern systems can handle an array of materials and products, from agricultural goods such as grains and fruits to plastics and glass containers. Such systems provide flexibility so that industries can constantly improve and enhance their processing lines to meet modern requirements and quality standards. Combining these benefits reinforces the notion that optical sorters will always be necessary to become more efficient, precise, and Eco-friendly.

In what ways can Automation cut down on Labor for Food Processing?

In the food processing industry, Automation comparatively diminishes the labor needed by making tasks more effortless, accurate, and less hands-on. Repetitive operations such as sorting, grading, or packaging can be done quickly and accurately using automated technology like robotic arms, automated guided vehicles (AGVs), and conveyor systems. For example, automatic sorting technologies can swiftly move through high quantities of products while controlling the quality of these products, thus lowering the need for manual labor and lessening the chances of mistakes.

As machines have become more sophisticated, robotic technologies can now be used in the portioning, slicing, and assembling of food products. These improvements allow facilities to maintain a high output with fewer workers, solving issues with understaffing while reducing costs. In addition, real-time process tracking and predictive maintenance can enhance efficiency even further due to integrated monitoring and data analytics tools.

Automated systems drive down costs and can contribute to workplace safety improvements. Using automated tools to replace physically demanding and riskier tasks enables food processing plants to make the workplace safer. This is essential for industries that desire to scale their output while still meeting quality, safety, and sustainability standards.

How does Automation affect Sorting Efficiency?

During the modern age of technology, automation has increased the sorting efficiency of industry manifolds as it has provided unparalleled accuracy while streamlining processes. Automated sorting systems with the latest sensors and machine learning capabilities can detect, recognize, classify, and sort products within astonishingly short periods. Such systems reduce the chances of human error, which guarantees the quality of work is the same even with massive-scale operations. For instance, automated systems in food processing can sort articles into several categories, like size, color, weight, and defects. These enable uniformity in production, which is hard to achieve with manual systems.

As earlier stated, automation utilizes advanced technology. As a result, it works significantly on the throughput, allowing a company to handle a significant volume of products without encountering bottlenecks. The data edited from industry-wide reports shows how automated sorting systems enable increases in processing speeds, surpassing the traditional methods by nearly 30%, which gives the most significant boost to productivity and automates everyday processes in a business. Not only does this work efficiently for managing operational expenditure, but it also delivers on the increased production cycles in competitive markets. Adopting automated sorting technologies is essential for quickly and efficiently meeting higher operational requirements.

What are the Benefits of Using a Color Sorter Machine?

How do color sorters reduce contamination from foreign materials?

Using a color sorter machine is crucial for maintaining the integrity of a product because it meticulously identifies and eliminates foreign materials. The color sorter uses high-resolution cameras to detect differences in color, shape, and texture using advanced imaging technology, which makes it easy to classify unwanted materials from the product. It is also able to separate products at very high speeds, employing the use of NIR or ‘near-infrared’ scanning and multi-spectral scanning to sort out contaminants such as stones, plastics, shattered glass, or anything that is colored wrong.

Moreover, color sorters have intelligent algorithms that enhance their precision, allowing the removal of even the tiniest particles of foreign material. Modern designs also come with adjustable parameters that allow for specific product and contamination level customization. This level of detail in sorting processes ensures a high level of cleanliness, thereby meeting strategic regulations in agriculture, food processing, and recycling industries while protecting the brand and consumers.

What is the cost-value benefit of adopting Color Sorting Technology?

Adopting color sorting technology is cost-effective because it provides savings and operational improvement over time. While these systems may require significant upfront investment, the labor, waste, and product loss savings often exceed the initial costs. For example, Automated sorting systems reduce the need for manual sorting, which tends to be labor-intensive and subject to mistakes. Companies can enhance their production line by improving quality while minimizing excess costs.

Another critical factor is the increase in product yield and quality. New Integrated color sorting systems have sophisticated sensors and detection mechanisms to ensure that only non-defective or contaminate items are removed. This results in higher usable output in many industries, especially agriculture and recycling. In addition, reduced waste increases profit and helps meet sustainability targets, which is becoming more critical across industries. Companies tend to notice that improved output quality makes them more competitive in the market, which leads to better profits.

Besides, compared to older technologies, these systems often use more modern designs that are energy-efficient and less costly to maintain in the long run. Even with regular calibration and infrequent updates, their maintenance costs remain comparatively high, meaning the savings generated exceed spending. Many organizations also state that they achieve payback in just a few years of use. Overall, color sorting technology guarantees positive economic outcomes and practically fulfills the rising needs for efficiency, sustainability, and high-quality products.

How do Color Sorters ensure consistency in production?

Color sorters consistently maintain production quality through sophisticated imaging and sorting technologies that systematically eliminate materials below a certain pre-determined quality threshold. High-definition cameras and other sophisticated sensors are fitted in these machines that can scan thousands of items per second for characteristics like color, shape, and size. Color sorters strive to increase accuracy while simultaneously decreasing the margin of error and ensuring consistency across batches by identifying and ejecting defective products or contaminants at a remarkably rapid pace. This is especially critical in agriculture, food manufacturing, and recycling, where there is little to no room for error in terms of quality.

Operators can configure color sorters with specific parameters that meet the needs of any given production process. From the food industry, where color sorters mark ripe and unripe fruits based on quality parameters, to many others, virtually every industry can benefit. This flexibility in adaptability helps reduce waste and improve productivity, as machines can efficiently sort many materials with different attributes. Furthermore, modern systems are equipped with self-learning algorithms that enhance performance over time, making the system far more reliable in the long run.

Color sorters play an integral part in assuring production accuracy through data-driven insights. Today’s models also have the capability of real-time monitoring and reporting, enabling operators to have precise control over the sorting procedure. These systems can generate valuable analytics, helping producers identify trends, address inefficiencies, and predict maintenance needs. Such systems are highly reliable and help minimize downtime while maximizing the sustainability of operations. Technologies like these make color sorters indispensable when it comes to achieving modern production standards.

What are the Key Features to Look for in Sorting Equipment?

What types of Optical Sensors are used in Color Sorters?

Modern optical sensors are employed in color sorters to detect materials with great detail and accuracy. These sensors are essential in detecting the color, dimension, shape, and smoothness of an item or an object to be able to sort it correctly. Some common optical sensors used in color sorters are:

RGB Cameras: RGB cameras are important parts of RGB sensors, which can gather wide-ranging visual information. They break down colors into red, blue, and green components and analyze them so that a color sorter can differentiate minute changes in color.

Near Infrared (NIR) Sensors: NIR sensors have moderate infrared vision and are very useful for distinguishing between different types of materials. They can help determine the presence of contaminants or objects that are undesirable but may look like acceptable materials.

Multispectral and Hyperspectral Sensors: These sensors are advanced because their imaging scope is not limited to RGB but several other wavelengths. In addition to a higher multispectral sensor used for better color distinguishing, there are even more advanced ones known as hyperspectral sensors that measure materials for more sophisticated tasks.

Ultraviolet (UV Sensors): UV sensors can discern materials with ultraviolet-induced fluorescence, which can detect coatings, impurities, or degraded materials of interest.

Laser Sensors: When it comes to identifying faults like cracks in surfaces, discoloration, or small defects invisible to cameras, laser-based optical sensors do the best job.

X-ray sensors: Though not often seen, X-ray sensors may be utilized in unique situations to check internal features and ascertain that the underlying content meets the requirements.

Thanks to these sophisticated optical technologies, modern color sorters allow industries to comply with quality requirements, increase productivity, and reduce wastage, achieving accuracy that was previously unattainable.

What is the Contribution of CCD Technology to Sorting Accuracy?

Sorting accuracy is enhanced by CCD (Charge-Coupled Device) technology through accurate image capture and sensitivity to light and color. CCD sensors process images at a much higher speed than cameras. They can feel tiny changes in the materials’ size, shape, and color while offering accurate separation of objects. They convert the light striking them into an electric signal while generating very little noise, giving sharp images necessary to identify defects or impurities during the sorting process.

Because this technology can function under different types of lighting, it guarantees reliable performance, especially in industrial applications. The machine also uses sophisticated algorithms to determine real-time sorting within captured data. CCD-based systems are particularly useful in agriculture, food processing, and recycling, where quality can have drastic repercussions. CCD technology helps reduce waste while increasing efficiency in many systems by ensuring accuracy.

Why are High-Capacity Sorting Machines Important?

High-capacity sorting machines are crucial in time-sensitive or labor-intensive processes. They can process, automate, and sort large amounts of materials much faster, making it more manageable in terms of the time and labor required for sorting manually. These systems can automate the sorting process to a great extent using advanced functionalities like artificial intelligence, machine learning, and even optical sensors, making it easy to sort materials based on shape, size, color, and composition.

The recycling industry allows for the faster separation of metals, plastics, and papers, making for a cleaner final product with lesser contamination rates. In agriculture and food processing industries, high-capacity sorting machines enable rapid sorting based on the product’s ripeness, defects, or size. This ensures compliance with the set quality standards. They help streamline workflows, reduce operational costs, lessen waste, and maximize resource utility. They offer cleaner and more effective solutions for industrial processing, meeting the demand for efficient, scalable solutions in the current pace-focused market.

Frequently Asked Questions (FAQs)

Q: How does a color sorting machine function?

A: A color sorting machine relies on sophisticated optical sorting technology. An optical system sorts out the products being processed due to their color differences while moving through a chute. The machine incorporates sensors like CCD or InGaAs that notice impurities and defects simultaneously. This allows for effective filtration of contaminants and foreign materials.

Q: How does a color sorter enhance the quality control sequence of a food sorting operation?

A: The contamination levels in food sorting operations are best managed with optical sorting machines, which remove impurities based on color discrimination. Those actions guarantee that only good-quality products like green coffee and pistachios will reach the production line.

Q: Is a color sorter suitable for sorting plastics?

A: Indeed, color sorters can sort out plastics due to color differences and types of plastics and, therefore, facilitate the attainment of higher-quality recycled plastic products.

Q: Which products are the most suited for optical color sorting?

A: Optical color sorting can be employed in an extensive range of products, including food like lentils, walnuts, and confectionery. It is also used in non-food products like plastic. This adaptability makes it useful for different sectors.

Q: In what ways does the sensor technology in a color sorter make it more effective?

A: The sorter’s sensor technology, such as RGB and NIR, makes the color sorters more efficient because it enables them to see the smallest color differences and specific defect sizes. These improvements aid greater processor line productivity and quality control.

Q: What benefits come with using a belt-type color sorter?

A: A belt-type color sorter has many benefits. For instance, less gentle treatment of products, which leads to more breakage, has increased throughput. This is ideal for removing well-handled delicate products like green coffee and confectionery items.

Q: How does deep learning technology improve optical sorting machines?

A: Optical sorting machines’ usability is enhanced with deep learning technology that allows the machine to learn and adjust to different sorting criteria. This feature enables the machine to produce greatly differing colors and varying defect sizes and ensure high-quality outcomes.

Q: What kind of assistance and support is offered regarding color sorter machines?

A: Most manufacturers have service and support contracts that cover the installation, maintenance, and troubleshooting of color sorter machines. This is important to guarantee machines work optimally while meeting the rigid food hygiene requirements.

Q: Does manual sorting still play a role in optical sorting?

A: Manual sorting can be used as a supplementary activity when checking the finished products for faults that the machine may not detect. Combining both aids in attaining the optimum quality requirements.

Q: In what manner does a color sorter remove diseased and contaminated products from the line?

A: A color sorter uses color recognition to find and eliminate unhealthy processed goods based on the distinct color that flaws such goods. This feature guarantees that only clean goods free of contaminants are dealt with subsequently.