An electric water pump(Find more info now!), whether installed in a home, workplace, or garden, can make managing water flow much easier and efficient. Learning how to install each electric pump will further enhance its effectiveness and lifespan, saving time and money in the long run. This article is aimed at helping you with everything you need to know about electric water pumps, guiding you step by step through the process with ease that anyone can manage. Regardless of whether or not you are familiar with such tasks, this article will teach you all the necessary concepts and insights to ensure that the task is executed without added difficulty or problems. So, be prepared to gather the recommended tools and expert tips to make the process easy!

What are the Different Types of Water Pumps?

All You Need To Know About Submersible Water Pumps

Submersible water pumps are efficient and versatile devices designed to work fully underwater. They can be used in applications like draining flooded regions, providing water for irrigation systems, or managing wastewater in residential, commercial, or agricultural settings. Unlike conventional pumps, submersible ones are constructed to prevent water from entering their motor and electrical components, ensuring safe and durable operation underwater.

Submersible pumps can be distinguished from other types by their capacity to push water to the surface rather than pulling it out, allowing for lower energy consumption and higher efficiency. Additionally, they can be constructed from robust, harsh condition-resisting materials like thermoplastics and stainless steel. For example, some models of submersible pumps can handle high-pressure debris and other solids, making them ideal for use in septic tanks or drainage systems.

The most important features of a submersible water pump include the flow rate, head height (maximum lift), and pump power rating. The flow rate measures the amount of water the pump can move within a specified period (usually GPM or L/s). The head height tells us how much water the pump can lift, which is needed in tasks like groundwater harvesting. Understanding these factors helps one choose the best-suited submersible pump.

Exploring Sump Pumps and Their Uses

A sump pump is a specially designed device for preventing water from flooding basements and property depressions. Two primary types of sump pumps are pedestal and submersible.

The pedestal sump pump is easily recognizable from the rest by the elevated motor, which sits above the sump pit mounted to a column. This design keeps the motor dry, maximizing its life and making periodic maintenance easy. Pedestal models tend to be cheaper than their submersible counterparts and are best suited for use cases where water inundation is unlikely.

Submersible sump pumps, in contrast, are specifically designed to sit below the water line in the sump pit. Fully submerged in water, these pumps benefit from noise-dampening provided by the pump’s casing. These pumps are more efficient at removing large amounts of water, perfect for areas with heavy flooding.

Some essential performance indicators of sump pumps are their capacity (in gallons per hour or GPH), power (usually in horsepower or HP), and head height (the height water can be lifted). A household sump pump, for example, may be able to manage flow rates of 2,000-5,000 GPH, along with 25 feet of head height.

Efforts to improve the efficiency and reliability of modern sump pumps have led to the incorporation of advanced technologies. The ability to operate automatically with float switches means the pump engages only when necessary, and the backup battery systems protect the pump during outages. Innovative models even allow users to track the pump’s performance and water levels and get alerts for low levels or malfunctions, providing seamless monitoring.

Sump pumps serve commercial and residential properties. They protect basements from structural damage, safeguard crucial business documents and valuables, and prevent hefty losses associated with overflowing control. Choosing a specific type of sump pump necessitates careful considerations such as the amount of water expected, the size of the pit, and how frequently the pump will be utilized.

What are Utility Pumps and Their Applications?

Utility pumps are multi-functional pumps that involve moving water from one place to another for various uses. These pumps can remove water from flooded areas, empty heaters full of water, or transfer fluids from one tank to another. They serve a very important purpose regarding water management in homes and industries. Utility pumps come in two forms: submersible and non-submersible, and can be used for numerous water removal projects, including removing stagnant water from a basement or swimming pool.

Since utility pumps are easy to operate, adhere to compact structures, and have lightweight designs, they are suitable for occasional or temporary use. Most utility pumps handle clear water. However, some models can hold a small amount of dirt or debris, which increases their versatility. As with any equipment, the flow rate, head height capacity, and power source must be checked for adequate performance with a utility pump. These pumps provide convenience to users and serve as a reliable solution for draining water with little effort.

How to Choose the Right Water Pump for Your Needs?

Choosing the Right Water Pump

Choosing a water pump requires carefully considering many aspects to ensure maximum productivity and suitability to your preferences. To begin with, analyzing the flow rate which is the speed measurement of the pump’s movement through a given space usually in gallons per minute (GPM) or liters per second (L/s) is a good start. Consider the application requirements, whether low or moderate for household tasks and high for irrigation.

Then, evaluate the pump’s water-pushing capabilities, aka the ”head height,” which is the maximum height to which the pump can push water. This is extremely important for applications with large vertical distance spans, like pumping water from wells or to elevated tanks.

Moreover, look at the pump’s power source. Electricity, gasoline, diesel, and solar energy can provide a pump’s power source. Electric pumps work best in homes and city areas where power is stable and readily available. Gas or diesel-powered pumps are best for heavy-duty applications in remote locations without access to electricity. Solar provides a sustainable solution for off-grid locations.

Evaluating a water pump’s durability is equally important. A pump made from strong stainless steel or plastic materials will perform better during prolonged operations or when subjected to harsh conditions. In addition, consider what type of pump is the best fit for this specific task. For instance, submersible pumps are the best for removing water from flooded spaces or for drawing water from deep locations, while centrifugal pumps are the best choice for moving high quantities of water in a short time.

Lastly, the ease of operation and maintenance of the water pump should be considered. Choose the design that is easy to clean and maintain, with the lowest lead time needed to be achieved and downtime for servicing the water pump’s spare parts. Meeting these demands will allow a water pump to be selected for a specific task and guarantee the required performance.

Evaluating Your Water Source and Flow Needs

Evaluating the water source ahead is necessary to know what type of pump to use and guarantee it functions properly and efficiently. Water sources can be shallow wells, deep underground aquifers, rivers, lakes, or water collected from rainfall. Each of these sources has unique attributes like the water’s quality, depth, and the quantity available, all of which can affect the choice of the pump. Take, for example, a fountain; if a body of water has high sediment, a pre-filtration system or a pump that is resistant to abrasive materials will be necessary.

Evaluate flow requirements as equally critical. These requirements are defined by the water volume needed for your application, measured in gallons or liters per minute (GPM or LPM). Additionally, you must establish total dynamic head (TDH), which includes vertical lift and friction loss in the piping system. Accurate flow rate and TDH calculations not only guarantee peak operational efficiency for your pump but also prevent water delivery shortfalls, excessive energy costs, and other complications.

When dealing with deeper sources or more complicated systems, pump pressure capacity and efficiency ratings become additional concerns. Evaluating your water source alongside the flow parameters in a methodical, data-oriented manner makes it possible to tailor solutions to your needs reliably while ensuring reliable and sustainable system management over time.

Assessing Electric and Manual Pumps Side By Side

When choosing the two options, key features, capabilities, and applicability should always be considered for manual pump systems and their electric counterparts. Electric pumps are easily the most efficient because they rely on electricity and require little human effort, especially considering their ability to move large volumes of water. It can be used to run farms and for industrial processing where continuous delivery is needed. However, their power supply dependency means they face greater chances of failing, and their operational costs may worsen during harsher times.

Human-powered manual pumps are far easier to design, making them more practical in remote locations where power is not available and unreliable. These pumps are typically implemented at lower installation costs, with easier maintenance, and a lower environmental impact. However, operating these pumps can be strenuous and inconvenient during excessive use, which makes them in demand for large-volume applications.

In these cases, assessing budgetary and sustainability policies along with energy requirements makes the decision less difficult. Even though manual pumps are unmatched in off-grid and emergency scenarios, electric pumps surpass them in efficiency and scale.

What Tools and Accessories Do You Need for Installation?

Basic Equipment Needed for DIY Water Pump Installation

Copies of specialized tools are unnecessary; however, some generic tools may work in installing a water pump. These tools include, amongst others:

Pliers: Pipe wrenches and pliers are necessary when gripping or tightening movable pipes. The additional force required when gripping pipes is provided using these tools.

Drilling and Drill Bits: An equally reliable drilling machine is needed to guarantee the precise setting up of pumps.

Teflon Thread Tape: All threaded fittings require these items to ensure leak-proofness. Without these steps, work efficiency would be compromised due to leaks.

Tape Measure: Any spacing and alignment errors must be dealt with, so proper measurements must be checked during the installation process.

Vulcanizing Hose Cutter or Hacksaw: Cutting pipes to length is necessary when dealing with setups involving plastic piping systems.

Voltmeter or Multimeter (only for electric pumps): Before work can begin, both these items confirm that all the power wires are connected appropriately and ensure all safety procedures have been adhered to.

Adjustable Wrench: These enable the tightening of the nuts and bolts regardless of their size, which may be used when mounting the pump to the various parts of the piping system.

Installation Gloves: The process is actually dangerous, so ear protection, gloves, and safety goggles must be worn.

A well-equipped toolset enhances the installation accuracy and equipment longevity while reducing potential errors on the water pump system.

Essential Accessories For Enhancing Water Pumps’ Functions Include:

In the pursuit of increased reliability and performance of the water pump system, acquiring the right accessories is vital. Some valued water pump accessories will improve operational flexibility and functions.

Pump Control Switches: These accessories help control the operational functions of the water pump to increase its running efficiency. Options include pressure switches that automatically turn on and off, while float switches allow for water level monitoring.

Check valves: These accessories are placed in the pump piping systems to prevent the backward flow of water or leakage, which protects the pump from damage while maintaining balanced pressure.

Priming Kits: These simple yet effective kits enable easy priming and starting airless pumps by providing water and removing air from the systems.

Pump covers: These simple yet effective covers protect the external pumping units from factors such as rain, UV rays, and dirt, thereby increasing their lifespan.

Hoses and fittings: Proper and adequate connection in the water transferring systems is ensured through the usage of good, durable hoses and adequate fittings, which all help reduce the chances of leaks.

Water Filters and Strainers aside, cleaning up debris and particles helps protect the pump’s efficiency and shields it from clogs and possible damage.

Flow Meters: These instruments enable real-time water usage monitoring, improving system operational data, and supporting conservation efforts for energy and water.

These accessories enable proper functioning and increase the longevity and effectiveness of the water pump system.

Choosing the Right Hose for Your Pump

A few essential considerations must be kept in focus when picking the right hose for your pump in order to achieve maximum performance and longevity. One of the most important factors is the size of the hose. Selecting an appropriate hose diameter corresponding to the pump will help maintain correct flow rates while preventing unwanted pressure drops. The material selection is also critical. Depending on the application and environmental conditions, materials can vary from tough rubber to flexible PVC to heavy-duty reinforced hoses. If the pump deals with abrasive or corrosive materials, consider a hose with a specially designed liner that improves resistance and increases lifespan.

Length is another one of the most important considerations. Longer hoses facilitate extended reach; there is a hose length threshold that must be observed, going beyond which can cause friction losses and increased efficiency loss. Checking the hose pressure rating is also essential to ensure it can withstand the pump output pressure without failing explosively. If a pump operates in extreme hot or cold temperatures, the capability to withstand high temperatures during pumping needs to be checked. Considering all these factors will facilitate the selection of a hose that enhances the efficiency and reliability of the pumping system.

How to Properly Install a Water Pump?

Complete the Installation of Electric Water Pumps in a Few Steps

Clear the Installation Area: All locations where the pump will be placed should be arid, well ventilated, and clean. Avoid survey areas that are prone to deep flooding and areas with moisture, as these will greatly affect the electrical parts of the pump. Make sure sufficient space for maintenance or adjustments is conveniently available as well.

Check if the Power Supply is Adequate: Check if the power supply is compatible with the pump’s power voltage and amperage settings. The pump’s power supply must have its individual circuit breaker and a ground Fault Circuit Interrupter (GFCI) to minimize the risk of live wire issues. Always adhere to local electrical rules and regulations.

Position the Electric Water Pump Properly: The electric water pump should be placed on a concrete or mounting base pad to absorb any vibrations. It must also be placed on a stable surface and secured with proper fasteners to avoid movement caused by wear or damage during operation.

Join the Piping System: Use proper fittings to attach the inlet and outlet pipes to the pump with clamps. If possible, use flexible connectors that can readily absorb vibration or thermal expansion, which increases the durability of both the pump and pipes.

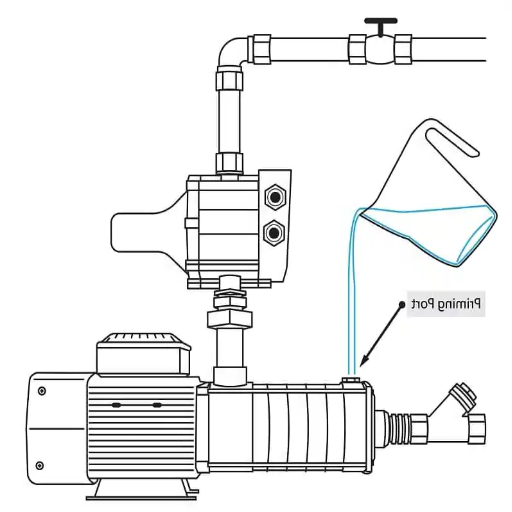

Priming the pump: Priming the pump involves cleaning the pump casing by expelling air from the system. If the pump is not self-priming, fill the casing with water. The pump casing must be filled. Skipping this step can lead to disastrous dry runs, damaging the pump.

Check the alignment and sealing: Inspect all pipes and fittings in accordance with the alignment order and seals. Misaligned seals and components result in reduced efficiency and increased leaking.

Testing the system: Set up electrical power and activate the pump. Monitor water flow and pressure discharge gauge to determine expected results. Always shut down electrical power if malfunctions occur. Listen for unwanted sounds and check for unusual vibrations as well.

Now, you can install electric water pumps with a low risk of damage, failure, or operational complex issues. Following the manufacturer’s maintenance checklist, together with the operational guidelines, will enhance the system’s effectiveness and extend its service life.

Connecting the Pump with the Water Source

Connecting the electric water pump to the water source requires excellent attention to guarantee precision and efficiency. Like any other task, you need to locate the correct inlet and outlet ports on your pump. The manufacturer labels these parts, and good-quality and strong parts must be used for compatibility with the setup. These connections are critical to ensure no leaks or pressure drops take place.

Seal all threaded connections with plumber’s tape for enhanced watertightness. Always ensure the pump is placed where the inlet pipe is fully submerged to prevent air from entering the system, which can cause cavitation. Achieving a balance between direct and short positioning of the suction line will assist in reducing friction loss. Additionally, appropriate pipe diameters must be utilized for the pump specifications.

Also, installing a strainer or foot valve at the water source is important to prevent debris from entering the pump and causing damage. A non-return valve can be added to maintain steady water pressure and prevent backflow when the pump is off. Confirm that the system functions properly after all connections are made. Look for a smooth flow of water without leaks, constant pressure, and no abnormal sounds. Establishing these connections properly will extend the lifespan of your pump while improving efficiency.

Check Your Installation Work For Performance Purposes

Its performance must be tested to ensure that it prevents future complications and keeps the pump installation working smoothly. First, make careful checks on the water pressure within the system to ensure it is not reading below or above the recommended range. If the water pressure fluctuates, your system may have misalignment issues, leaks, or blockages. After this, you may also want to check how much energy is being consumed, detailing the electric usage of the pump, for comparison to other pump models. Reduction of excessive energy consumption indicates parts inefficiency due to internal wear, worn-out motor, and so on.

All joints and connections should also be checked for leaks. Small snippets of water don’t seem like much, but over time, they can degrade the performance of the entire installation or result in excessive wear and tear. Also, listen for other unusual sounds like grinding or vibrating noises, which might indicate deeper-seated mechanical issues such as worn bearings or a misaligned impeller.

Lastly and most importantly, record the working temperature of the pump on sustained operation and how long it has been running at a stretch. Constant overheating is one of the most damaging long-term risks to any system, and its long-term unrestricted water flow or lubrication sufficiency issues. Performance testing ensures catching all the measurable problems preemptively before major repairs are vital to the system’s maintaining functionality.

What Maintenance is Required for Water Pumps?

Regular Checks and Maintenance Tasks

So that the water pumps work optimally, I have created a set of routine checks and maintenance tasks. These help postpone expensive repairs and increase the water pump’s life. To begin with, I check the pump physically for any obvious signs of damage, such as cracks in the housing, loose bolts, or corrosion, which are the primary indicators of wear and tear. Moreover, I scrub off any dirt or acts that may lead to clogging, especially around the seals and the impeller, as these areas are highly susceptible to blockages. This practice alleviates undue burden on the pump and guarantees its proper functioning.

Next, alignment and lubrication take the forefront. Bearings greatly influence friction and overheating, so proper lubrication of these components is vital. The manufacturer has specific instructions on how much and what type of lubricant to use. Also, I check that there is no excess, which might result in component damage. Finally, I check that the pump and motor shafts are accurately aligned to eliminate vibrations that will cause mechanical strain.

Lastly, I track the electrical interfaces and system functioning as monitor checks or control analyses, academic. Monitoring for electrical fires, component looseness, and corrosion helps mitigate power-related risks. I also perform periodic performance evaluations to assess relative pressure outputs, flow, and temperature compared to accepted operating norms. Routine checks such as these have helped me achieve sustained operational efficiency of the pump and system-wide confidence in when the pump is called upon to become less reliant on minimal settings.

Fundamental Problems and Problem-Solving Strategies

One fundamental problem that frequently arises is the drastic reduction of pump performance, which is often associated with obstructed filters and flow systems. In this case, I investigate the intake and discharge of all inflow and outflow pipes for possible obstruction. Pumping the obstruction out or cleaning the filters usually restores the pump’s functionality. Cleaning these components must be done more regularly to become treated as a form of confusion inhibition.

There could be unusual noise or vibrations during the pumps, which might be surprising. Cavitation is often a result of air entering the pump system or a pump being run at the wrong pressure values. To fix this, I look for any leakage in the suction line while confirming that the pump is primed to avoid dry running. Operating parameters like flow rate and pressure also influence the smoothing out of cavitation and are thus a solution, too.

Overheating is another thing I sometimes deal with. This comes from an over-lacking lubrication on moving components or too much friction due to general wear and tear. As for the seals and bearings, I replace them as needed and check their respective cooling counterparts. Maintenance on these parts decreases the pump’s chances of overheating while concurrently extending its service life. Adhering to a methodological systematic approach makes resolving these issues straightforward, allowing the pump to be dependable for more extended periods.

When to Seek Professional Help for Repairs

I seek professional help when a certain repair job looks difficult because of the required expertise, tools, and spare parts. Some complex issues are severe electrical malfunctions, damage to an impeller, or leaks in the internal system. These advanced issues often involve diagnostic equipment and technical knowledge that only a trained technician possesses. Without the necessary expertise, attempting to fix these problems may lead to more damage and safety hazards.

If the troubleshooting steps performed show that the pump still operates poorly or the system is not routinely maintained, then that is enough reason to call a professional. Those nagging issues are likely symptoms of more complicated system problems that require evaluation and partial reconstruction. They are best solved by professional repair services, whose experts are trained to manage these problems while making the pump safe and efficient.

In the end, even though I’m sure I can manage many routine repairs and diagnostics, I appreciate recognizing my limitations. In this instance, the right kind of help is brought in exactly at the right time. This helps deliver a more dependable solution and keeps the pump lasting longer by solving problems before they evolve into far greater issues.

Reference Sources

- Rural Water Supply Systems – Penn State University

- Installing Hand Pumps – Technical Note – Penn State University

- Domestic Water Pumps Installation Guide – Michigan State University

- Sump Pump Questions – North Dakota State University

- Water Pump Replacement Guide – Ford Powerstroke Diesel Forum

Frequently Asked Questions (FAQs)

Q: What are the basic essentials when installing a water pump?

A: To set up a water pump, an operator should have a pump unit, a tank, piping, a shaft seal, gaskets, and some form of electrical connection. Depending on the type of pump to be installed (this could be the centrifugal or a well pump), a timing belt or drive shaft may also be included.

Q: What factors must I consider while purchasing a water pump?

A: As a rule of thumb, it is essential to consider the water to be handled (for instance, potable or sewage water), the intended flow rate (gpm), the lift height, and whether this will be for irrigation, dewatering, or frequent transfer. Also, the power output (HP), material(e.g., stainless steel), and overall design should be considered for the dependability and effectiveness of the water pump.

Q: What steps can I take so as not to overheat the water pump?

A: To ensure consistent optimal temperatures, avoid overheating by confirming the appropriate plumb and coolant levels, ensuring the pump’s overall settings are close to the desired temperature, and periodically checking the windows for signs of wear. In a washing machine, this could be the radiator and shaft seal. Allowing the pump to run without water and keeping the housing chamber clean and devoid of grime enhances the optimal performance temperature.

Q: How do well pumps differ from other types of pumps?

A: Well pumps, such as shallow well pumps, jet pumps, and deep well submersibles, will always be tailored to draw water from subsurface sources. Their design is typically robust to withstand the lift needed to raise water from a well to the surface. They are built differently from other types of pumps, whose operations are more of a transfer or sewage of water without lifting it very high.

Q: What is the role of the engine in a water pump system?

A: The engine in charge of the water pump system operates the pump by turning its crankshaft, forcing water through it. The engine is electrically powered for electric pumps, but for other types, it may be belt-driven. In this case, the engine’s functioning is critical in providing a constant flow and discharge while preventing the pump from stalling.

Q: Can a water pump be used to dewater a flooded basement?

A: Yes, water pumps, such as trash or heavy-duty water pumps, are very effective in removing water from a flooded basement. They are specifically made to deal with refuse and effectively move large quantities of water. Just make sure that the pump you use is appropriate for removing debris and water from the site.

Q: What measures can I take to guarantee the long-term reliability of the operation of water pumps?

A: Water pumps must be routinely checked and maintained like every other machine. Inspect and renew gaskets, seals, and timing belts as necessary. Pay attention to the cleanliness of the housing and components of the pump. Clean and lubricate all moving parts, and check electrical connections as well. Ensure that the pump is working optimally and check for any problems proactively.

Q: What advantages do stainless steel water pumps have?

A: Stainless steel water pumps are water—and corrosion-resistant, making them suitable for safely transporting drinking water and other fluids in hostile conditions. They are also reliable and sustained without deformation, functioning properly for long periods without failure.

Q: Can you explain how a centrifugal pump works?

A: Centrifugal pumps are used to move water or other liquids. They utilize a motor-driven impeller (which looks like a fan) to suck water in through a pipe, achieving movement by rotation. The water then moves towards the center of the impeller due to centrifugal force. The high kinetic energy water in the outlet transforms into pressure when it enters the discharge pipe. It’s designed so that pumps can move and raise water over different distances and heights.

Q: What safety precautions must I take when installing a water pump?

A: As with any electrical equipment, ensure the pump is grounded and does not pose an electrical hazard. Also, remember to take all possible steps according to the described procedures, such as using the needed equipment and safety garments. In addition to those, pay attention to the device’s working power, don’t get too close to its moving components while it is on, and don’t forget to check the system periodically for any leaks or degradation or damage.